Rotary shaft crusher capable of intelligent overload control and overload control method of rotary shaft crusher

An intelligent control and crusher technology, applied in the field of hydraulic system control, can solve problems such as easy interruption of production continuity, production line shutdown, and low production output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

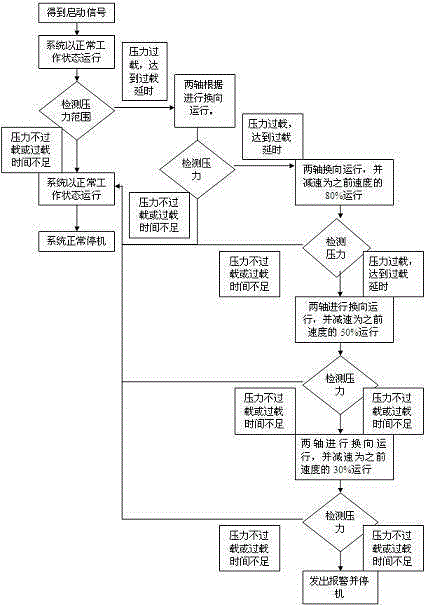

[0029] The hardware part of the rotary shaft crusher described in the present invention includes related electrical components equipped to realize the whole set of procedures: PLC controller, pressure sensor, reversing component controller (such as electromagnetic proportional reversing valve), hydraulic system, at least two rotating shafts Wait.

[0030] The system software part is a pressure segment control module, including a pressure detection unit, a main cycle mode control segment unit, a pressure overload information storage unit, and a shaft mode control unit.

[0031] The pre-set operating mode information of each rotating shaft and its corresponding reversing state information and speed information are implanted in the pressure overload information storage unit.

[0032] The pressure detection unit is used to control the pressure sensor to detect the pressure value analog signal of the hydraulic system, and transmit the pressure value analog signal to the PLC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com