Preparation method for after-treatment hydrocracking catalyst

A hydrocracking and catalyst technology, which is applied in the field of catalysis, can solve the problem that the active metal cannot reach a high accumulation layer, and achieve the effects of high selectivity, high hydrogenation activity, and high hydrogenation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

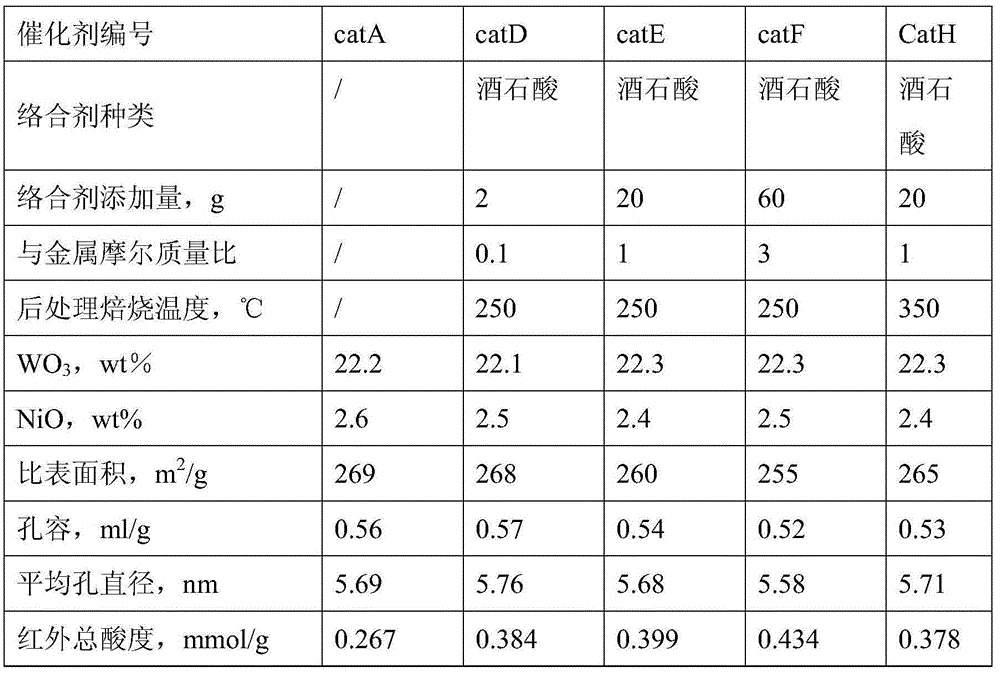

Embodiment 1

[0030] (1) Carrier preparation

[0031] The method is the same as the preparation method in Comparative Example 1.

[0032] (2) Catalyst preparation

[0033] Take 10g of nickel nitrate and 29g of ammonium metatungstate, dissolve them in 70ml of aqueous solution, and then use the equal volume dipping method to immerse the W-Ni co-dipping solution on 80g of carrier A for 2 hours, dry at 110 °C for 6 hours, and bake at 350 °C for 2 hours. hours, the catalyst catC was prepared.

[0034] (3) Catalyst post-treatment

[0035] Dissolve 2g of tartaric acid in 15ml of water, then dilute to 70ml, and impregnate it onto 110g of catalyst catC by the equal volume dipping method, dry in the shade after 2 hours, dry at 100°C for 2 hours, and calcinate at 250°C for 2 hours to obtain catD.

Embodiment 2

[0037] (1) Carrier preparation

[0038] The method is the same as the preparation method in Comparative Example 1.

[0039] (2) Catalyst preparation

[0040] The method is the same as the preparation method in Example 1

[0041] (3) Catalyst post-treatment

[0042] Dissolve 20g of tartaric acid in 15ml of water, then dilute to 70ml, and impregnate it onto 110g of catalyst catC by the equal volume dipping method, dry in the shade after 2 hours, dry at 100°C for 2 hours, and calcinate at 250°C for 2 hours to obtain catE.

Embodiment 3

[0044] (1) Carrier preparation

[0045] The method is the same as the preparation method in Comparative Example 1.

[0046] (2) Catalyst preparation

[0047] The method is the same as the preparation method in Example 1

[0048] (3) Catalyst post-treatment

[0049] Dissolve 60g of tartaric acid in 15ml of water, then dilute to 70ml, and impregnate it on 110g of catalyst catC by the equal volume dipping method, dry in the shade after 2 hours, dry at 100°C for 2 hours, and calcinate at 250°C for 2 hours to obtain catF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com