Shoe sole cleaning machine

A shoe sole cleaning machine and screw technology, applied in the field of cleaning appliances, can solve problems such as waste of manpower, material resources and financial resources, dirty soles, troubles, etc., and achieve the effects of energy saving, ingenious design, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

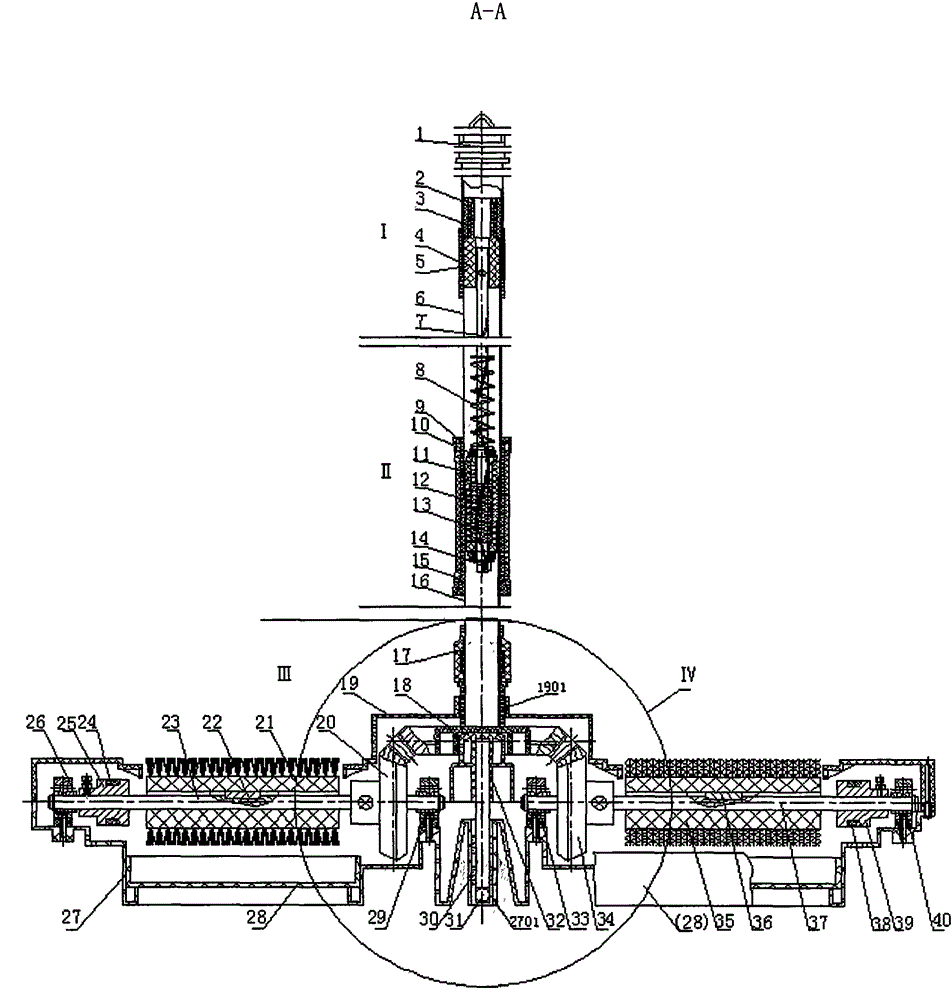

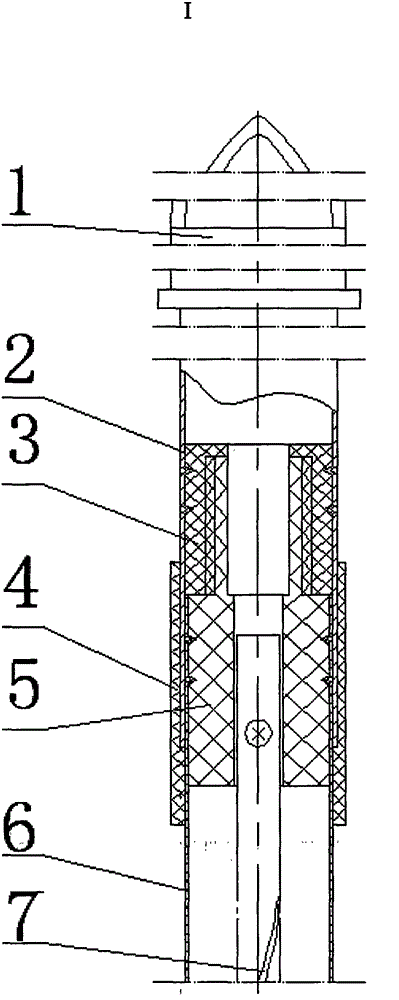

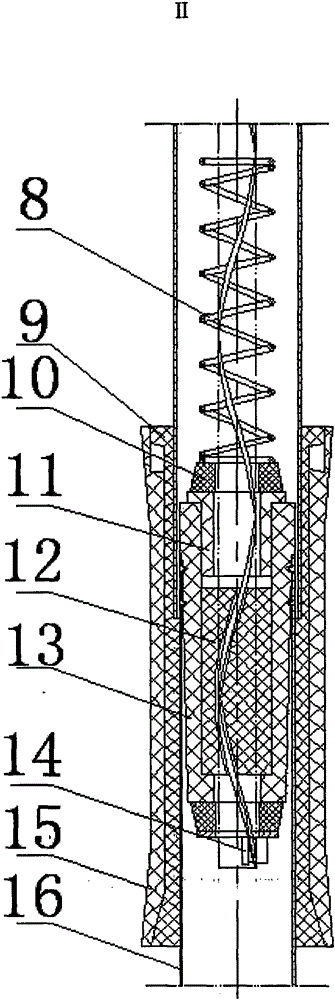

[0044] Figure 1 to Figure 3 Shown a preferred embodiment of the present invention, as shown in the figure, a kind of shoe sole cleaning machine of the present invention mainly is made of base, rotating shaft, main shaft body, bevel gear, roller brush and a screw rod mobile rotation device.

[0045] Base 27 is positioned at the lowermost end of this device, see figure 1 , Figure 1-04 , in the illustrated embodiment, the middle part is a conical cylinder that protrudes upwards, and there is a cylinder 2701 with a hole in the middle of the conical cylinder, leaving an installation space for installing the steel ball 31 and the main shaft body 32. A bearing 30 is installed in the cylinder 2701 .

[0046] On both sides of the middle part of the base 27, two pairs of left and right rear axles 23, right rear axles 37, left front axles 42, and right front axles 47 arranged in the same row, front and rear, are mounted on the base 27 by four pairs of bearing blocks respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com