Exquisite natural vermicelli machine with long whiskers

A pure natural, dragon beard noodle technology, applied in the direction of food science, etc., can solve the problems of short service life of stainless steel belt, large error in cutting length, uneven products, etc., and achieve less slag, high authenticity rate and high product quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment describe in detail:

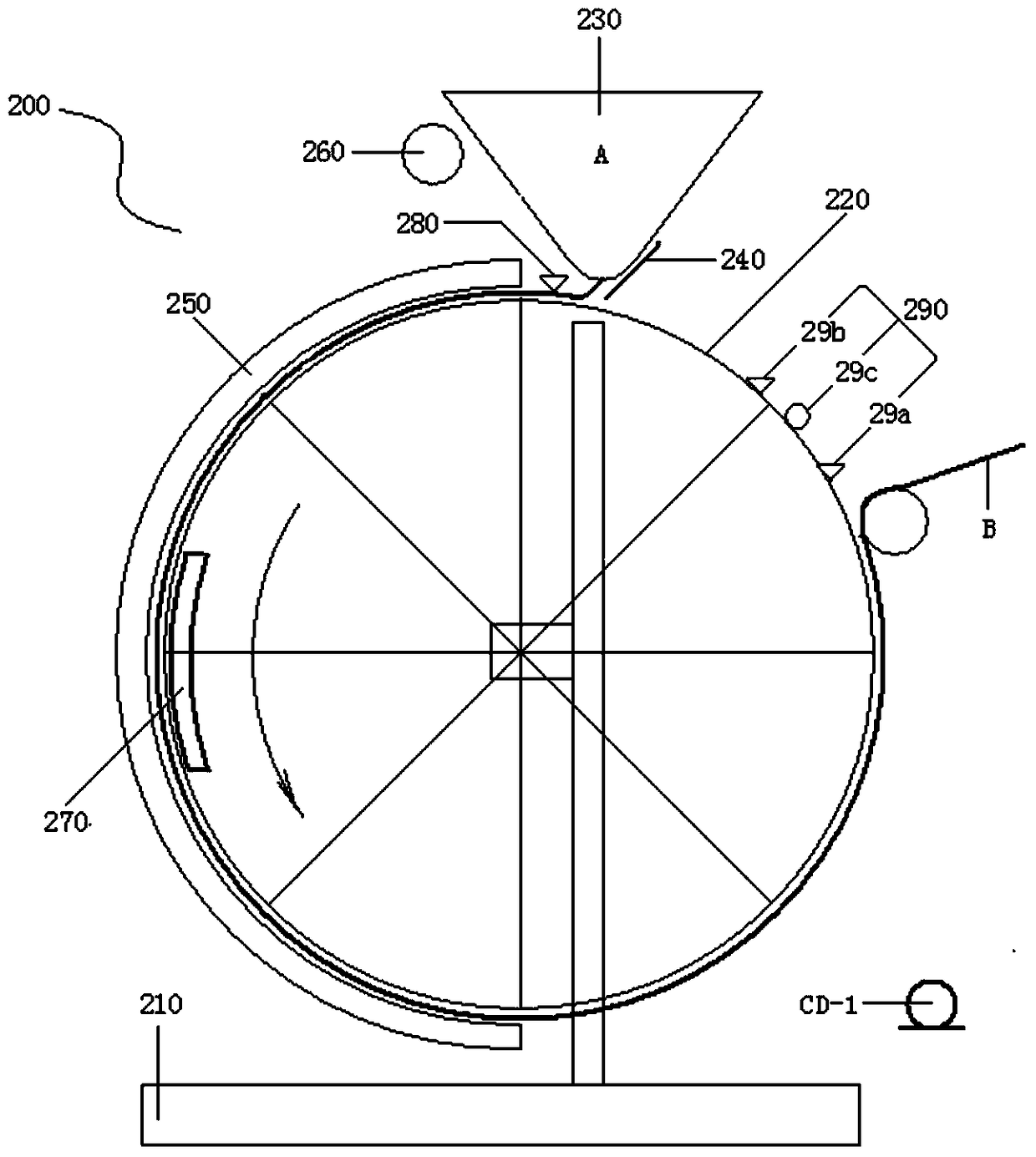

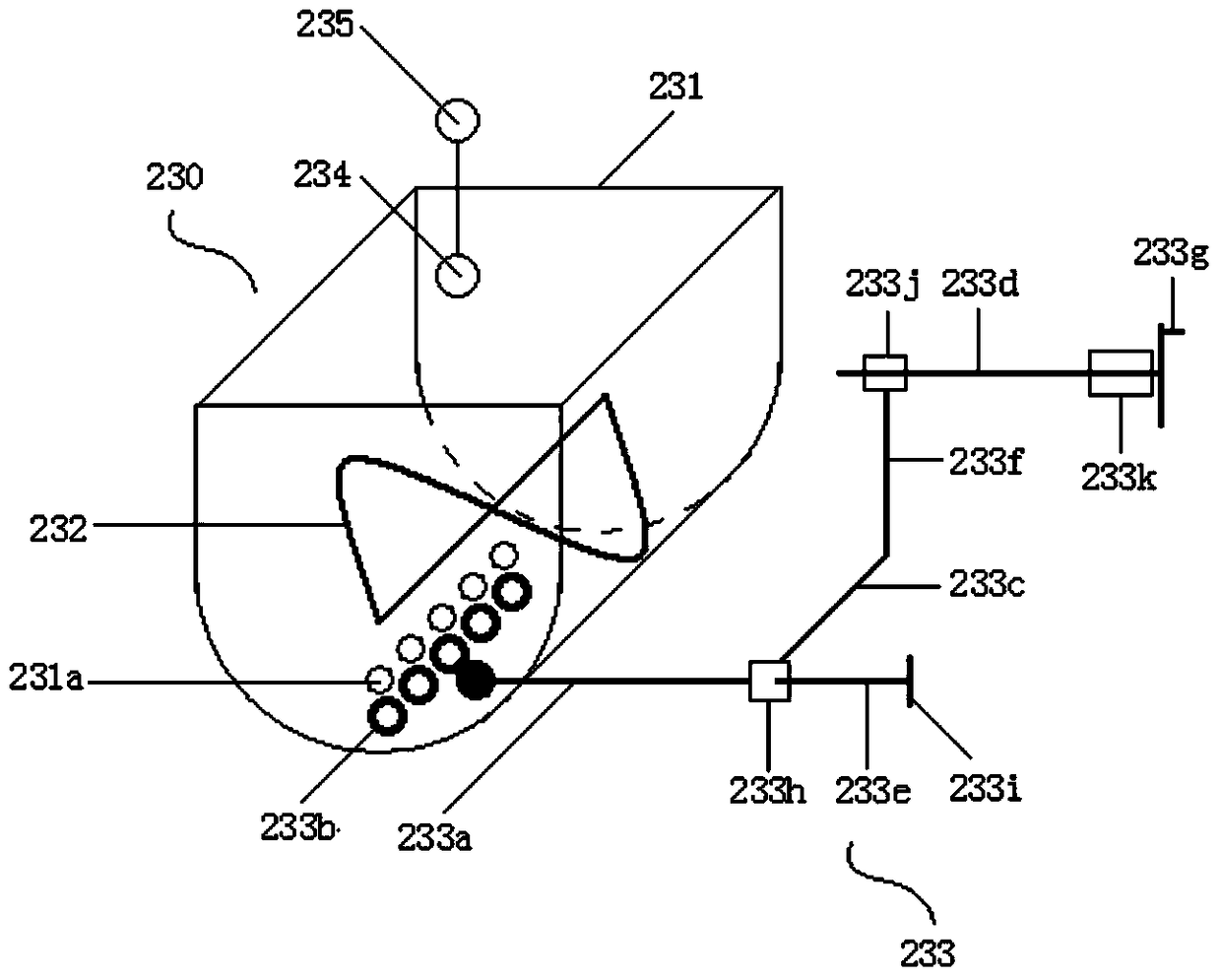

[0050] 1. The structure of the fan machine

[0051] 1. Overall

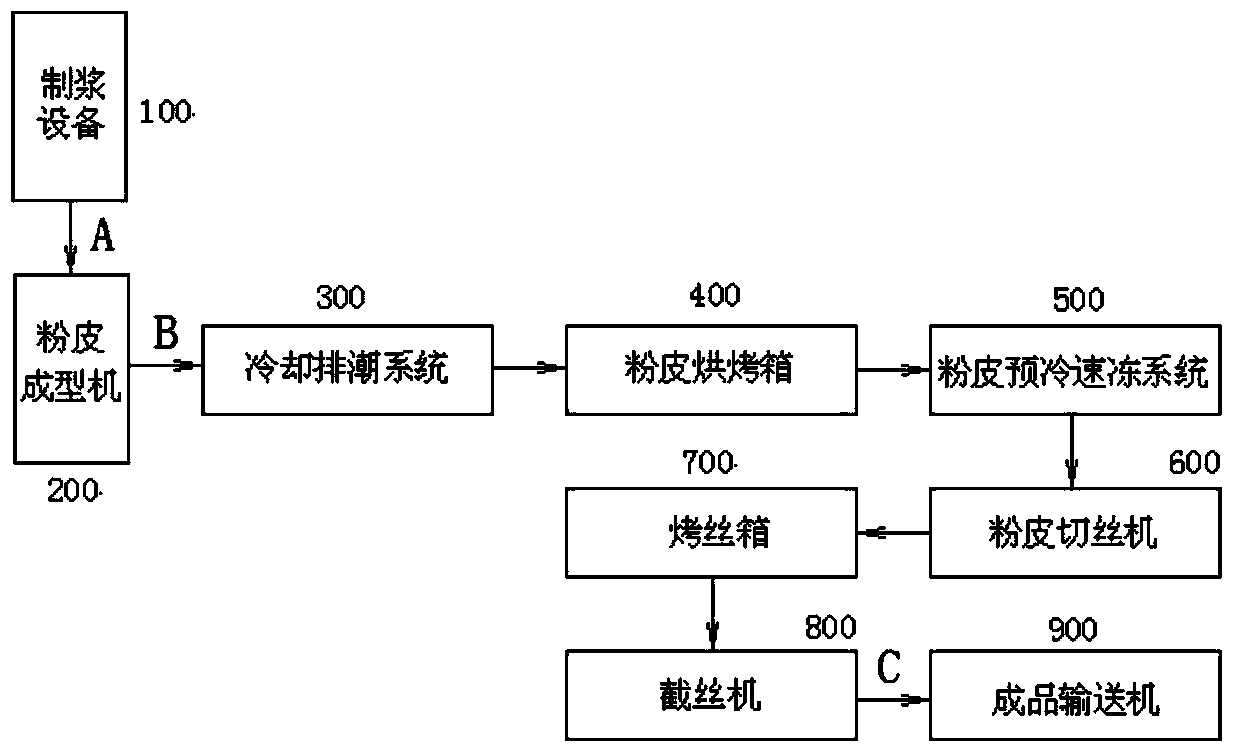

[0052] Such as figure 1 , the present invention includes existing pulping equipment 100, cooling and moisture removal system 300, vermicelli baking oven 400, vermicelli pre-cooling and quick-freezing system 500, vermicelli shredding machine 600, shredded oven 700, shredded shredded machine 800 and finished product conveyor 900;

[0053] A vermicelli forming machine 200 is provided;

[0054] Its connection relationship is:

[0055] Pulping equipment 100, vermicelli forming machine 200, cooling and moisture removal system 300, vermicelli baking oven 400, vermicelli pre-cooling and quick-freezing system 500, vermicelli shredding machine 600, shredded baking box 700, shredding machine 800 and finished product conveyor 900 in sequence connect.

[0056] Process flow of product processing:

[0057] Mixing slurry (water, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com