Preparation process and products of glazed tiles capable of forming patchy random crystallization effects

A preparation process and technology for glazed tiles, applied in the field of architectural ceramics, can solve the problems of good antifouling effect, uneven distribution of crystals, high flatness, etc., and achieve the effect of improving the suspension dispersion effect and clear crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

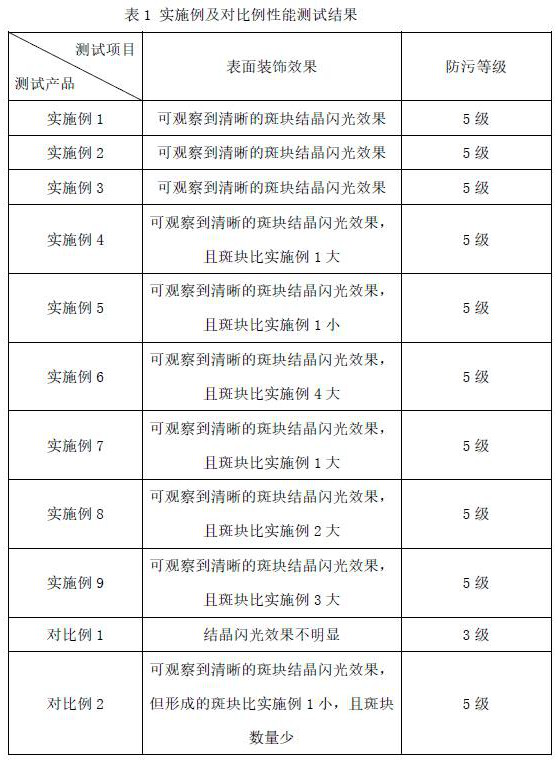

Embodiment 1

[0063] A preparation process for glazed tiles capable of forming plaque-like random crystallization effects, comprising the following steps:

[0064] A. Apply glaze on the surface of ceramic tiles, and then inkjet printing;

[0065] B, drenching the dry granular slurry on the surface of the ceramic tile (the specific gravity of the dry granular slurry is 1.55g / cm 3 , the slurry amount of the dry granular slurry is 600g / m 2 ), the raw materials of the dry granule slurry are crystalline dry granules, mixed transparent dry granules, suspending agent and transparent glaze, and the quality of the mixed transparent dry granules, the crystalline dry granules, the suspending agent and the transparent glaze The ratio is 25:15:25:10, the mesh number of the mixed transparent dry particles is 100-200 mesh, the crystal dry particles are zircon flash dry particles, and the chemical composition of the transparent glaze is SiO 2 60%, Al 2 o 3 18%, K 2 O 5%, Na 2 O 1%, CaO 6%, MgO 2%, ...

Embodiment 2

[0071] A preparation process for glazed tiles capable of forming plaque-like random crystallization effects, comprising the following steps:

[0072] A. Apply glaze on the surface of ceramic tiles, and then inkjet printing;

[0073] B, drench dry granule slurry on the surface of ceramic tile adobe (the specific gravity of described dry granule slurry is 1.45g / cm 3 , the slurry amount of the dry granular slurry is 600g / m 2 ), the raw materials of the dry granule slurry are crystalline dry granules, mixed transparent dry granules, suspending agent and transparent glaze, and the quality of the mixed transparent dry granules, the crystalline dry granules, the suspending agent and the transparent glaze The ratio is 30:15:30:15, the mesh size of the mixed transparent dry particles is 100-200 mesh, the crystallized dry particles are zircon glitter dry particles, and the chemical composition of the transparent glaze is SiO 2 60%, Al 2 o 3 18%, K 2 O 5%, Na 2 O 1%, CaO 6%, MgO ...

Embodiment 3

[0079] A preparation process for glazed tiles capable of forming plaque-like random crystallization effects, comprising the following steps:

[0080] A. Apply glaze on the surface of ceramic tiles, and then inkjet printing;

[0081] B, drench dry granular slurry on the surface of ceramic tile adobe (the specific gravity of described dry granular slurry is 1.5g / cm 3 , the slurry amount of the dry granular slurry is 600g / m 2 ), the raw materials of the dry granule slurry are crystalline dry granules, mixed transparent dry granules, suspending agent and transparent glaze, and the quality of the mixed transparent dry granules, the crystalline dry granules, the suspending agent and the transparent glaze The ratio is 20:10:30:10, the mesh size of the mixed transparent dry particles is 100-200 mesh, the crystallized dry particles are zircon flashing dry particles, and the chemical composition of the transparent glaze is SiO 2 60%, Al 2 o 3 18%, K 2 O 5%, Na 2 O 1%, CaO 6%, Mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com