Organic semiconducting blend

A technology of semiconductors and blends, applied in the field of organic semiconductor blends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

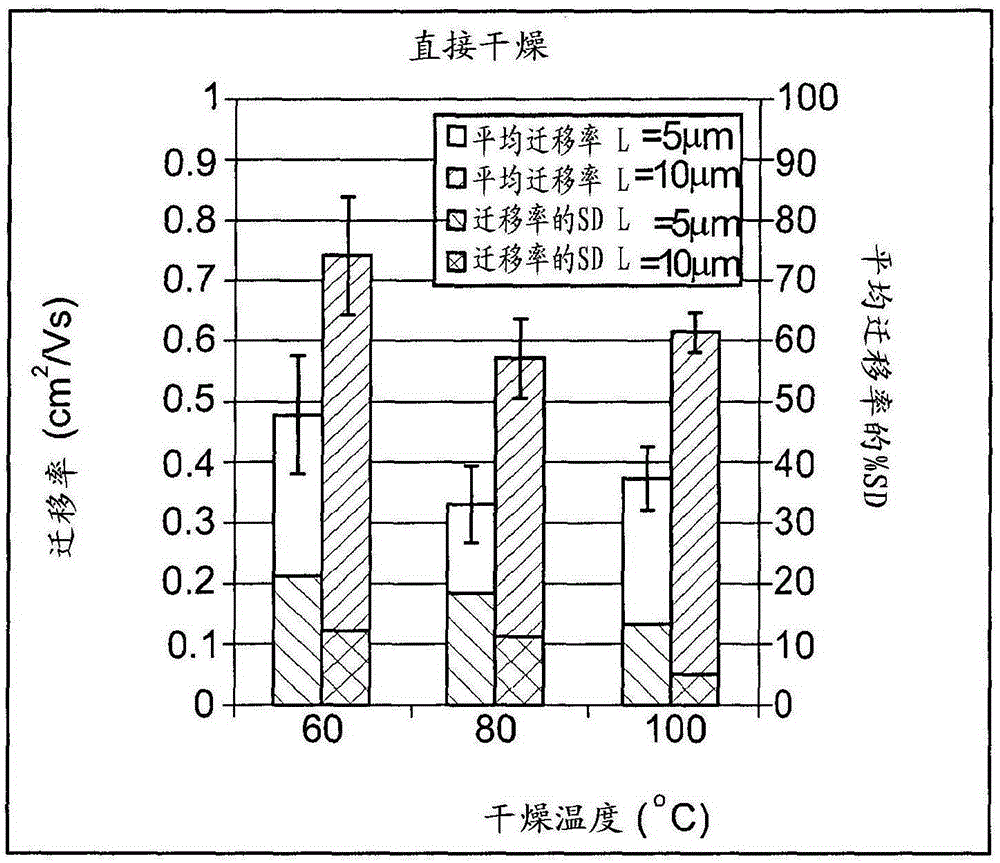

[0234] Material

[0235] Toluene and tetralin from Sigma-Aldrich

[0236] Fabrication Example of Organic Thin Film Transistor

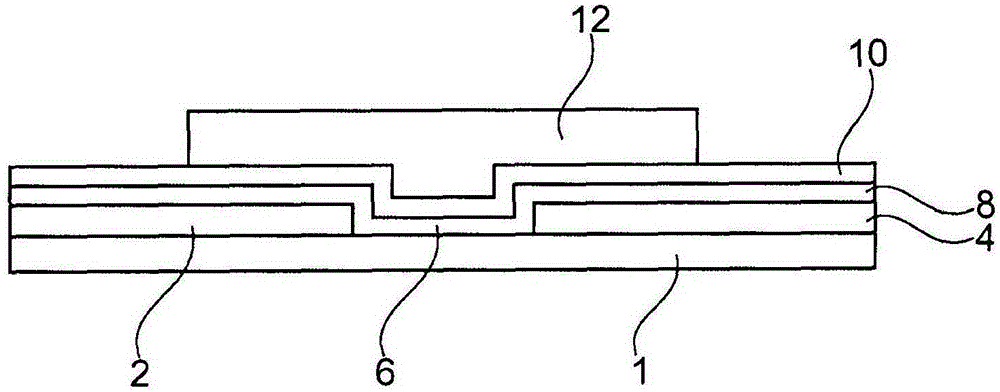

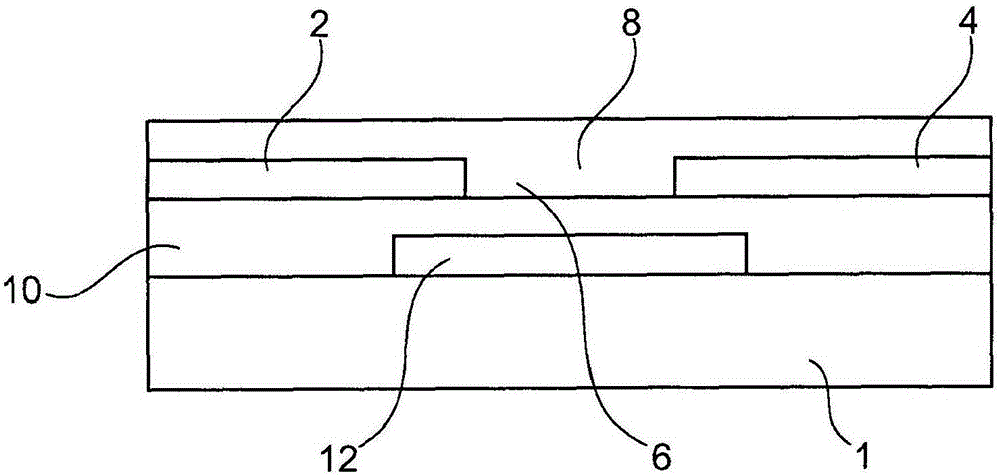

[0237] (i) Pre-cleaning of OTFT substrate and self-assembled monolayer (SAM) pre-treatment:

[0238] The first steps in device fabrication require pre-cleaning of the device substrate and application of surface treatment materials on the source and drain electrodes in order to ensure that contact resistance is minimized. The substrate consisted of gold source and drain electrodes (5 / 40 nmCr / Au) on top of a chromium adhesion layer on the glass surface. The substrate was cleaned by oxygen plasma to ensure removal of any remaining photoresist material (for source-drain definition).

[0239]After the plasma treatment, the electrode surface modifying compound (C 60 f 36 ). The solution was removed by spinning the substrate on a spin coater, which was then rinsed in toluene to remove any unreacted material that did not adsorb to the source and drain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com