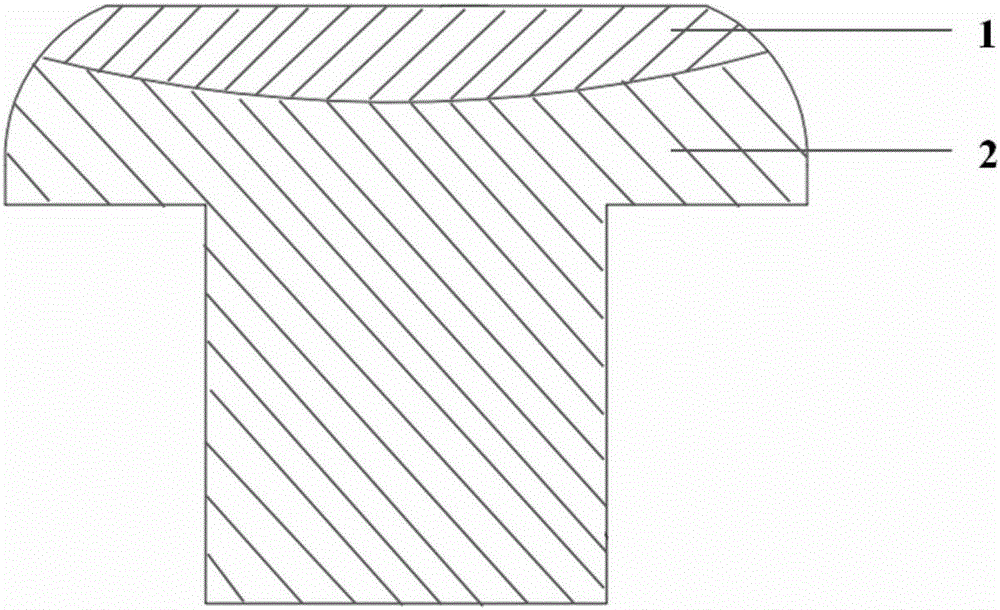

Copper-coated-with-silver graphene composite rivet contact and preparation method therefor

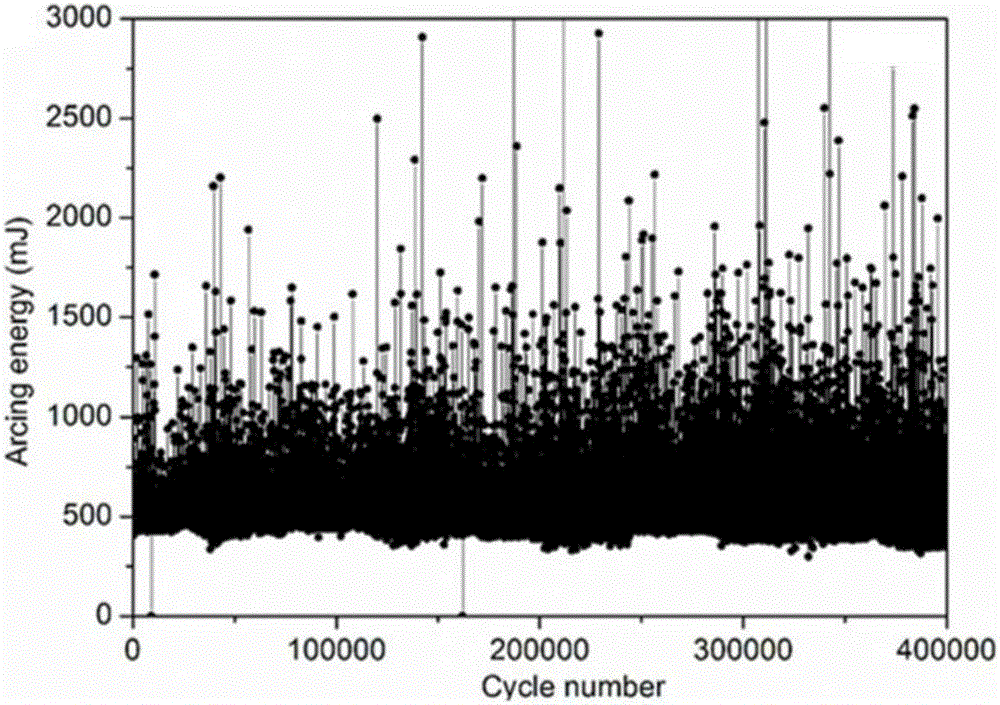

A silver-graphite, contact technology, applied in the direction of contacts, electrical components, electrical switches, etc., can solve problems such as upper damage, and achieve the effects of high electrical life, simple method and obvious electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The steps for preparing the AgGR / Cu double composite rivet contact in Example 1 are as follows:

[0047] Ⅰ) Material composition of silver graphene filaments

[0048]The material components of the silver graphene wire are mainly metallic silver and graphene, wherein the content of graphene is 0.5wt%-5wt%. Of course, in other embodiments, specific material components of the silver graphene filament can also be selected according to actual needs, and are not limited to those listed in the embodiments of the present invention.

[0049] Ⅱ) Steps for preparing AgGR / Cu double composite rivet contacts

[0050] 1) After the silver graphene powder was prepared by the chemical reduction method, the silver graphene wire with a diameter of 4mm was prepared by powder metallurgy and hot extrusion technology; the performance test of the obtained wire was found to have a resistivity of 1.53Ω· m×10 -8 ;The density is 10.31g / cm 3 ; Tensile strength of 190MPa; elongation of 42%.

[0...

Embodiment 2

[0054] The main difference from Example 1 is that this Example 2 increases the thickness of the silver-graphene composite layer.

[0055] The basic steps for preparing AgGR / Cu double composite rivet contacts in Example 2 are as follows:

[0056] Ⅰ) Material composition of silver graphene filaments

[0057] The material composition of the silver graphene filament is mainly metallic silver and graphene, wherein metallic silver accounts for 98wt%; graphene accounts for 2wt%.

[0058] Ⅱ) Steps for preparing AgGR / Cu double composite rivet contacts

[0059] 1) After the silver graphene powder was prepared by the chemical reduction method, the silver graphene wire with a diameter of 4mm was prepared by powder metallurgy and hot extrusion technology; the performance test of the obtained wire was found to have a resistivity of 1.53Ω· m×10 -8 ;The density is 10.31g / cm 3 ; Tensile strength of 190MPa; elongation of 42%.

[0060] 2) The silver graphene filament is placed in a hydrogen...

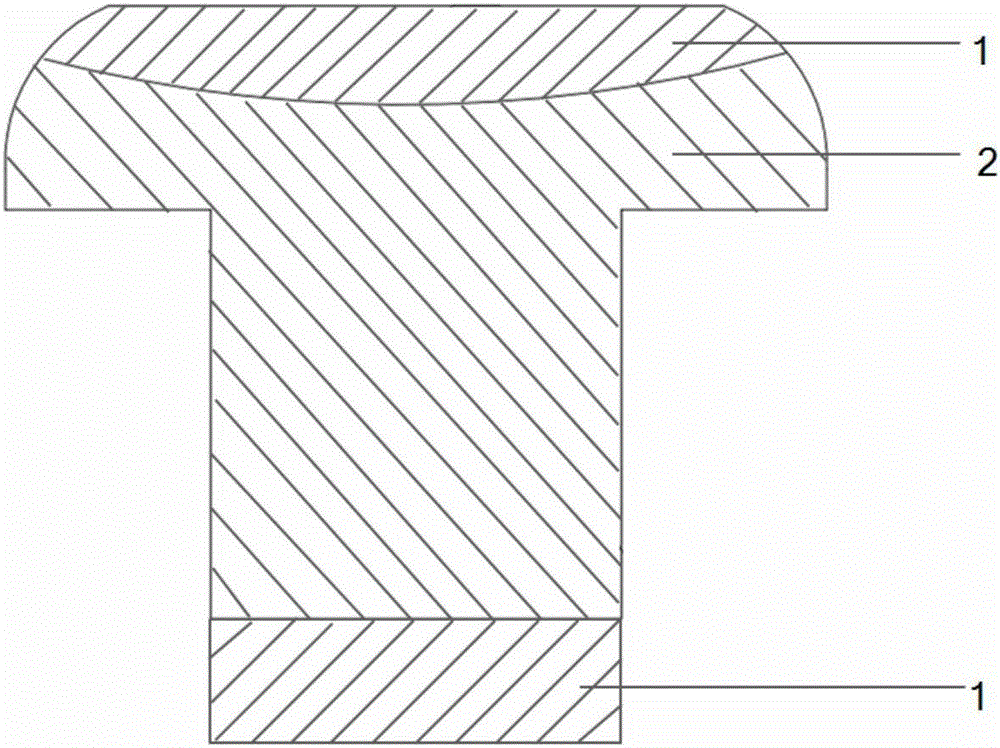

Embodiment 3

[0066] The steps for preparing the AgGR / Cu / AgGR three-composite rivet contact in Example 3 are as follows:

[0067] 1) After the silver graphene powder was prepared by the chemical reduction method, the silver graphene wire with a diameter of 4mm was prepared by powder metallurgy and hot extrusion technology; the performance test of the obtained wire was found to have a resistivity of 1.53Ω· m×10 -8 ;The density is 10.31g / cm 3 ; Tensile strength of 190MPa; elongation of 42%.

[0068] 2) The silver graphene filament is placed in a hydrogen environment, and annealed at 500° C. for 3 hours. Using a wire drawing machine, the silver graphene wire with a diameter of 4 mm is drawn into a silver graphene wire with a diameter of 2.5 mm.

[0069] 3) Using a three-composite rivet machine, the AgGR / Cu / AgGR three-composite rivet contact is prepared by compounding the silver graphene wire and the copper wire. The thickness of the silver-graphene composite layer on the upper surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com