Method for evaluating influences of double rotary tables on space errors of five-axis machine tool

A space error, double turntable technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult evaluation, weak influence of dynamic errors of rotating shafts, and no physical meaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing of description, the present invention will be further described.

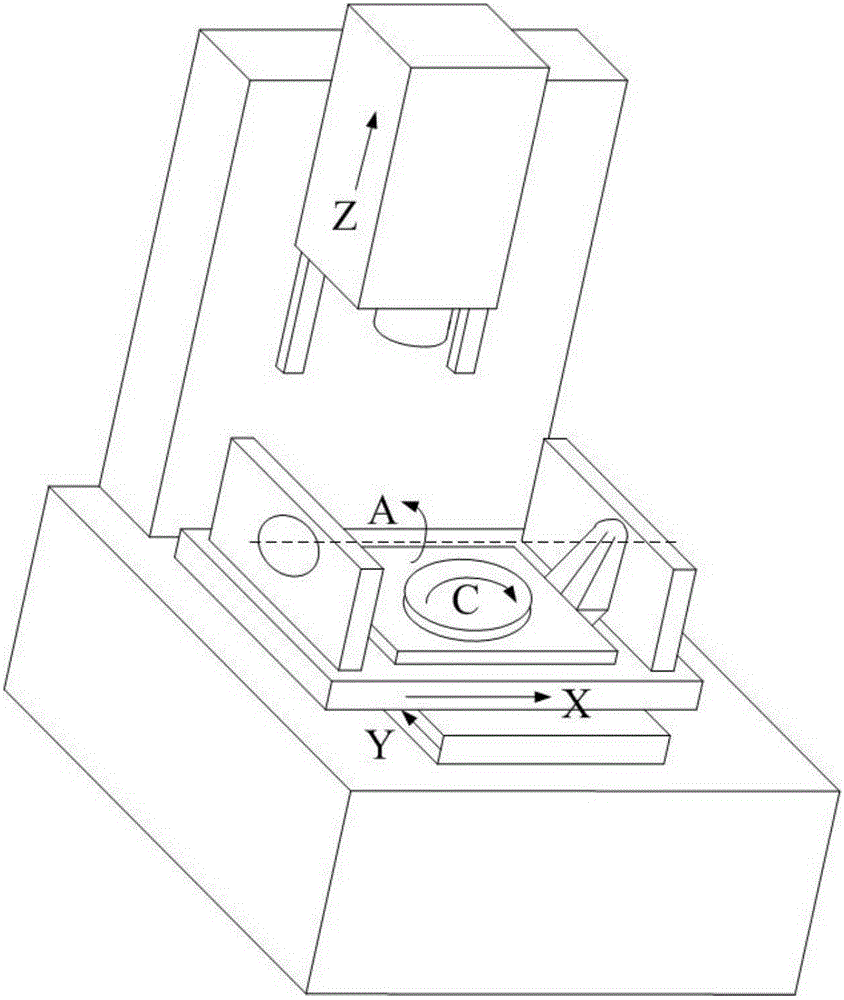

[0060] Such as figure 1 As shown, the embodiment of the present invention provides a schematic structural diagram of a vertical double turntable five-axis machine tool. The linear axes of the machine tool are X axis, Y axis and Z axis respectively, and the rotation axes are A axis and C axis respectively.

[0061] For ease of understanding, the process and effect of the present invention will be described below by taking the MCV850 vertical five-axis machining center (the numerical control system is iTNC530) as the specific implementation object.

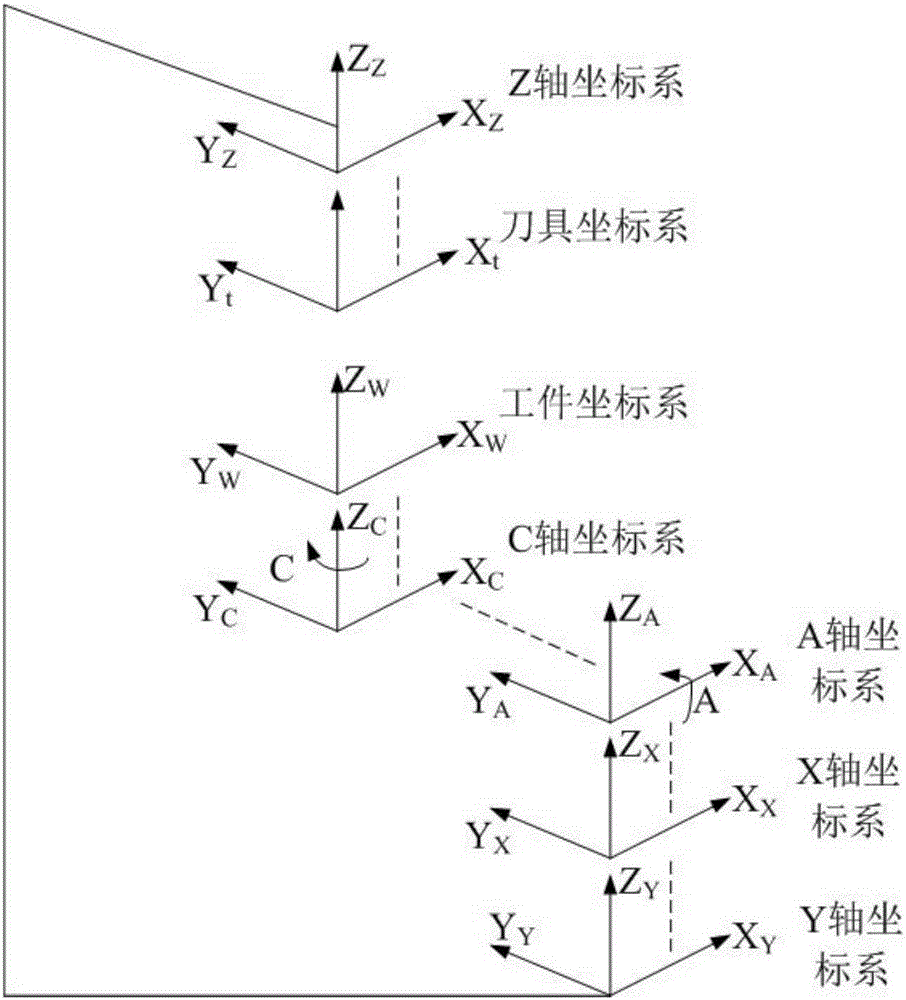

[0062] The A-axis stroke of the machine tool is -100°~120°, and the C-axis stroke is 0°~360°; after the detection of the ballbar and laser interferometer, β AX =0.002°, γ AX = 0.009°, α CA =-0.006°, β CA = 0.008°, δ xAX =0.002mm, δ yAX =-0.004mm, δ zAX =0.003mm, δ yCA =0.004mm, α YZ =-0.003°, β ZX =0.006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com