A hardware-in-the-loop performance test bench suitable for automotive c-eps system

A C-EPS and test bench technology, applied in the automotive field, can solve problems such as poor effect, poor repeatability, and no consideration of steering resistance motor mechanical system compensation, etc., to achieve the effect of reducing the effect of torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

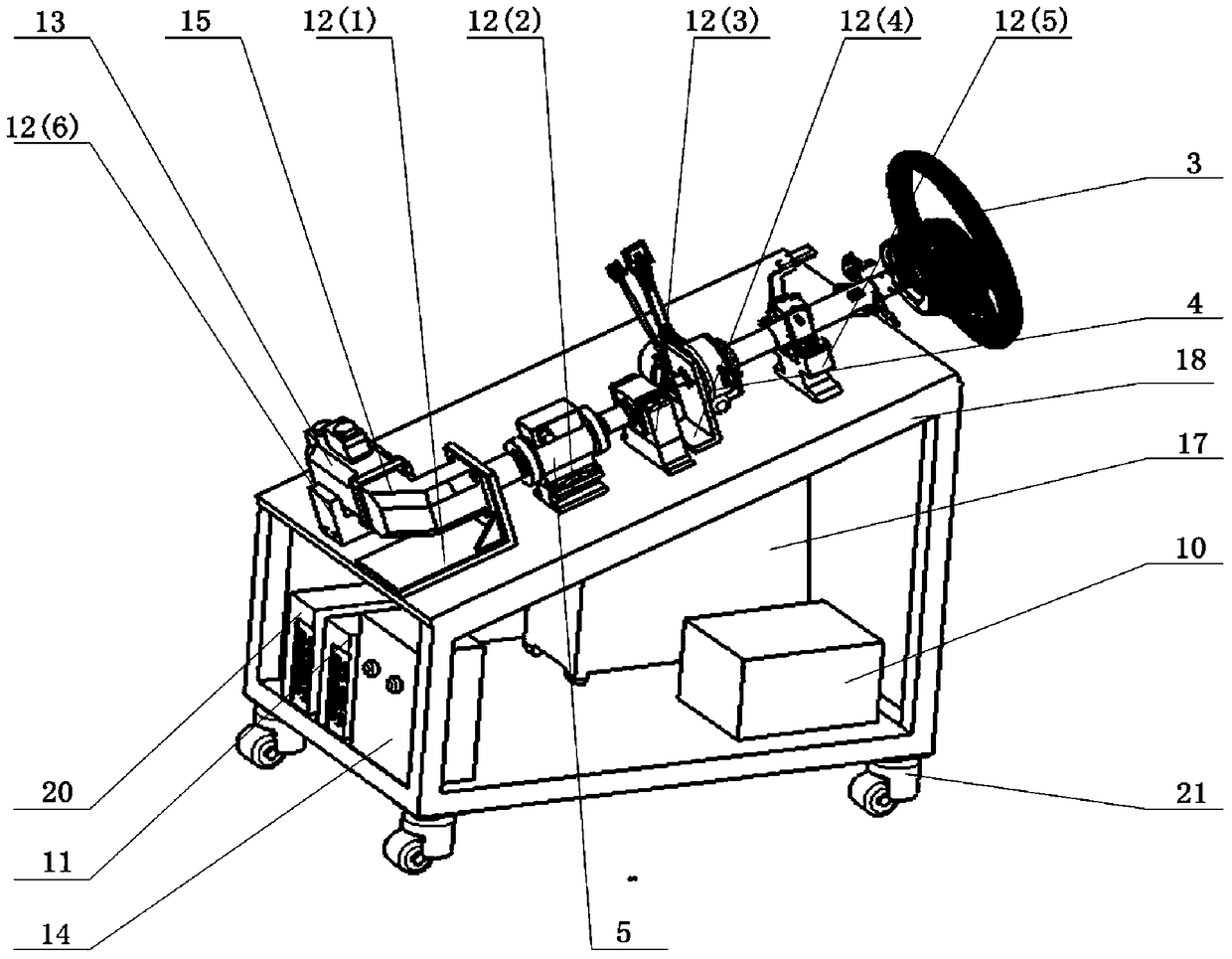

[0030] In order to illustrate the technical solution of the present invention more clearly, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

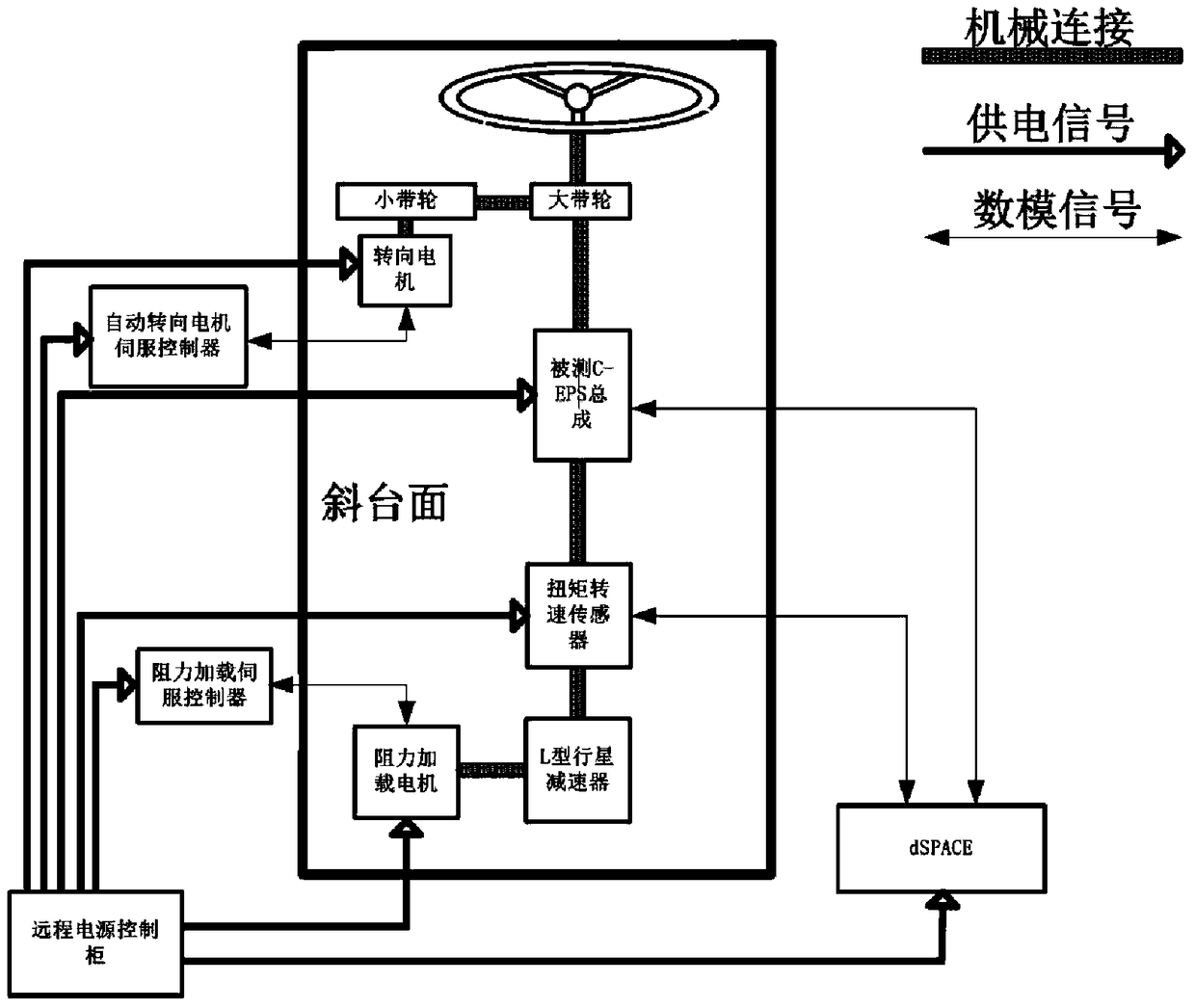

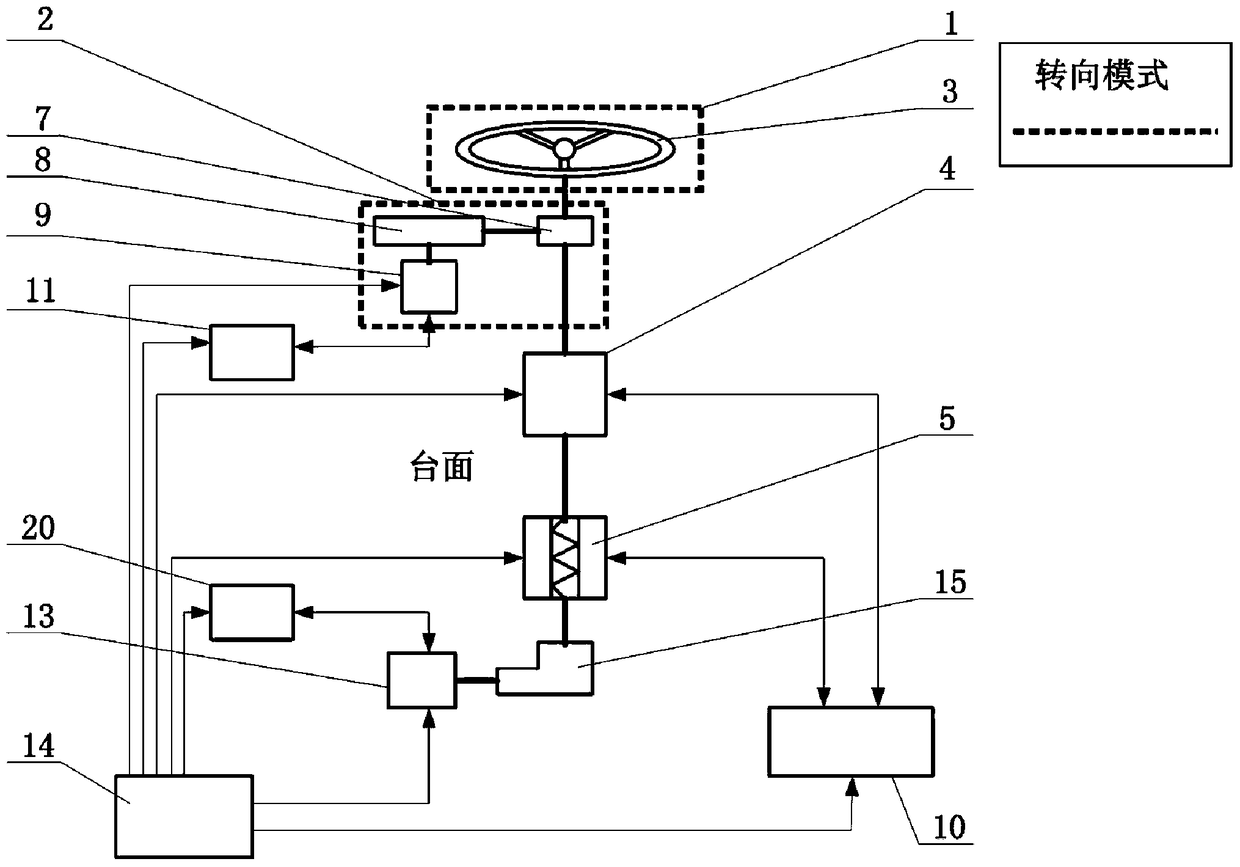

[0031] as attached figure 2 , attached image 3 , attached Figure 4 As shown, the present invention comprises: 1, the assembly of manual steering mode, 2, the assembly of automatic steering mode, 3, steering wheel, 4, tested C-EPS steering column assembly, 5, torque speed sensor, 6, Elastic coupling, 7. Automatic steering small pulley, 8. Automatic steering large pulley, 9. Automatic steering motor, 10. Real-time simulation platform dSPACE, 11. Automatic steering servo controller, 12. Position adjustable bracket, 13. Resistance Analog motor, 14. Remote control main power box, 15. L-type planetary reducer, 16. Connecting flange, 17. Industrial computer host, 18. Inclined aluminum alloy platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com