Scanner for ultrasonic scanning detection and locking-adjusting method thereof

A technology of ultrasonic scanning and scanner, which is applied in the direction of material analysis, instruments, and measuring devices using sound waves/ultrasonic waves/infrasonic waves. The effect of convenient adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

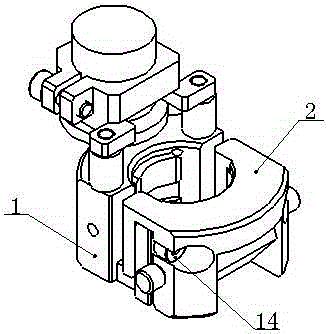

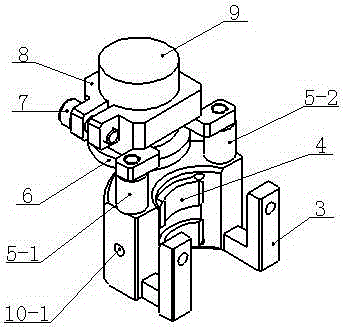

[0043] like figure 1 , figure 2 , image 3As shown, the scanner for ultrasonic scanning detection includes a left lock ring unit 1 and a right lock ring unit 2 connected with the left lock ring unit 1, and the left lock ring unit 1 includes a left outer lock ring 3 and a fitting The left inner lock ring 4 on the left outer lock ring 3 inwall, the left inner lock ring 4 can carry out the linear movement of the vertical direction with respect to the left outer lock ring 3, and the left outer lock ring 3 is provided with a vertical bar parallel to each other 5-1 and pole two 5-2, the bottom end of pole one 5-1 and the bottom end of pole two 5-2 are all fixed with left outer lock ring 3, the top of pole one 5-1 and pole The top of the two 5-2 is connected with the encoder swing seat 8 at the same time, the encoder swing seat 8 is provided with the encoder 9 and the fastening screw 7, the bottom end of the encoder 9 is provided with the encoder runner 6, and the encoder rotates ...

Embodiment 2

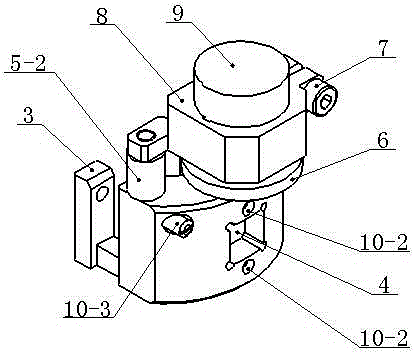

[0045] like Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, the left inner lock ring 4 is provided with a boss 4-1, and the boss 4-1 can move linearly in the centripetal direction relative to the stepped inner cavity 3-6 in the left outer lock ring 3, and the left outer lock ring 3 is provided with two threaded holes 3-4, and the stepped inner cavity 3-6 is arranged between the threaded holes 3-4, and the threaded holes 3-4 are provided with a plunger 10-2, and the plunger 1 10-2 Push the left inner lock ring backing surface 4-2 on the left inner lock ring 4 as a drive for linear movement of the boss 4-1 relative to the stepped inner cavity 3-6 in the left outer lock ring 3 in the centripetal direction force, the left outer lock ring 3 is provided with threaded hole 2 3-3, the threaded hole 2 3-3 is provided with plunger 2 10-1, the encoder swin...

Embodiment 3

[0047] The locking adjustment method of the scanner used for ultrasonic scanning detection: select the suitable scanner type for the outer wall 15 diameter of the small-diameter tube to be detected as required; align the inner cylindrical surface 4-4 of the left inner locking ring in the left locking ring unit with the Fit the outer wall 15 of the small-diameter tube, and keep this state; fit the inner cylindrical surface 12-3 of the probe wedge in the right locking ring unit to the outer wall of the small-diameter tube, and be in an up-down position with the left locking ring unit; make the right locking ring unit The right outer lock ring surface 2 11-5 of the probe wedge corresponds to the left outer lock ring surface 3-7 in the left lock ring unit; hold the right lock ring unit and push the left lock ring unit until it is close; pass The inner cavity of the right outer lock ring in the right lock ring unit 2 penetrates the locking screw 14, and is screwed in through two thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com