An Ultrasonic Phased Array Inspection Technology for Welds of Building Steel Structures

A technology of ultrasonic phased array and structural welds, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems that have not yet been applied, and achieve the effects of reducing safety accidents, shortening the detection cycle, and enriching non-destructive testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

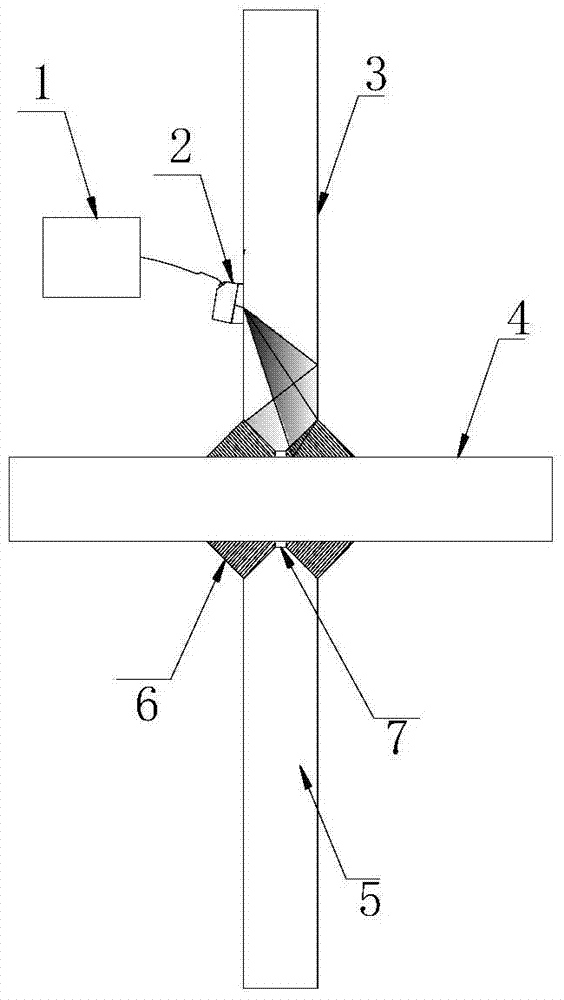

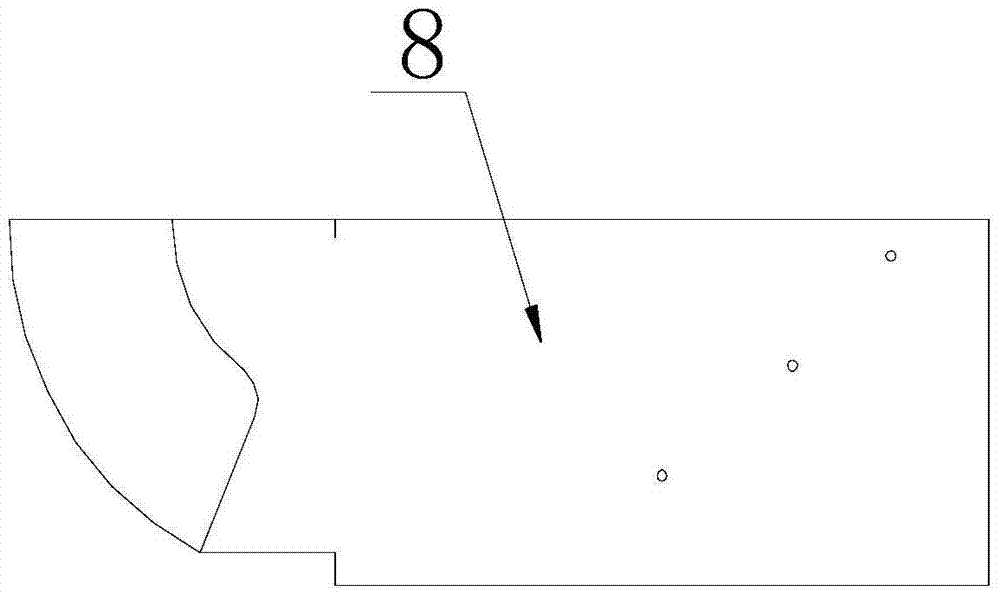

[0041] see Figure 1 to Figure 5 Shown: an ultrasonic phased array detection process for welds in building steel structures, the process uses an ultrasonic phased array detector 1 and an ultrasonic phased array probe 2 to detect welding defects 7 in the weld 6 of the weldment; The CSK-ID standard test block is used to calibrate the ultrasonic phased array detector, the RB-1A comparison test block is used to calibrate the detection sensitivity, and the RB-1B comparison test block is used to calibrate the size of vertical incomplete penetration and unfused defects.

[0042] Among them, the phased array instrument should at least have the functions of A, S, B, and C display, and have the functions of locating, quantifying and analyzing defects on the scanned image; it can store and recall A, S, B, and C images, and The stored detection data can be copied to the external storage space; the instrument software should have the functions of focal law calculation, angle gain calibrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com