Oil pipe inner coating leak point detection device

A technology for detection devices and inner coatings, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as non-coating, missed detection, and limited water content of conductive sponges, and achieve high accuracy and detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

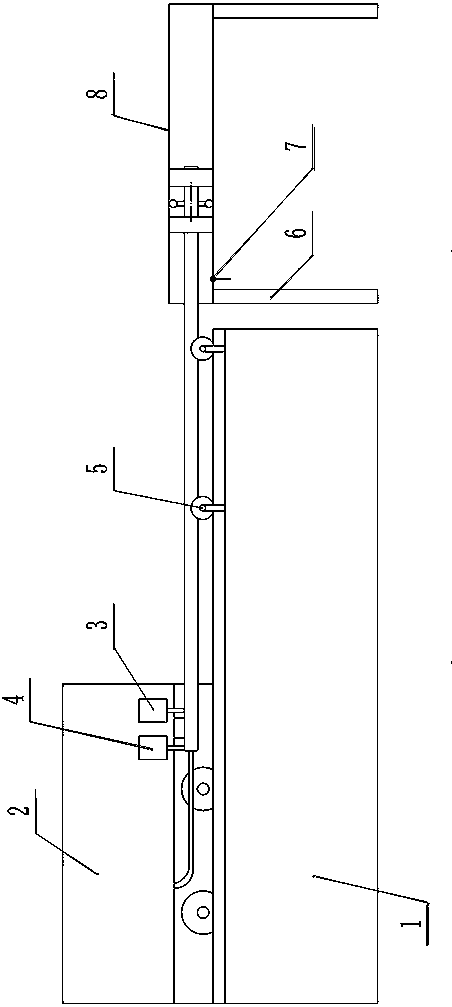

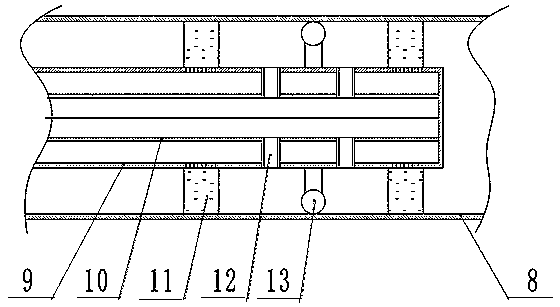

[0015] As shown in the figure, the oil pipe inner coating leak detection device includes a slide rail frame, a pulley is arranged on the slide rail frame, a detection tube is fixedly installed on the slide rail frame, and rollers are also arranged on the slide rail frame to support the detection tube , one side of the slide rail frame is provided with a bracket at the position opposite to the detection tube for placing the oil tube, and the terminal connected to the oil tube is connected to the detection computer; the detection tube includes an outer tube and an inner tube, and the inner tube is connected to the detection liquid pump. The outer tube and the inner tube form a ring space, the ring space is connected to the negative pressure absorption pump, the inner tube is connected to the space outside the outer tube with a through tube, the outer tube is equipped with a detection head, and the two sides of the detection head are provided with water-absorbing cotton, A hole is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com