Production method of artificial experimental sample imitating natural crack rock sample

A technology for making natural cracks and samples, applied in the field of rock and soil mechanics experiments, can solve the problems of high production cost, long production cycle, pollution, etc., and achieve the effect of improving molding quality and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with specific embodiment the present invention is described in further detail:

[0044] The flow process of artificial experimental sample manufacturing method of the present invention is as figure 1 As shown, it includes five steps of natural fracture rock sample estimation, 3D scanning, pouring mold modeling, 3D printing, and pouring molding. These 5 steps are described below with examples.

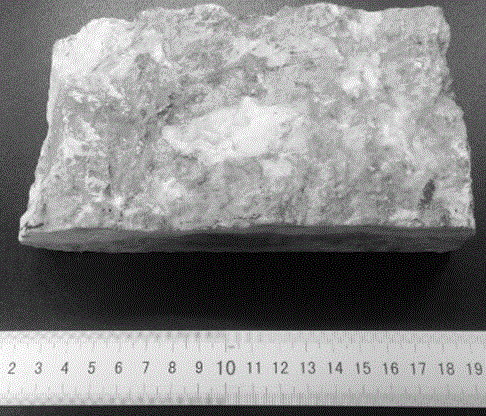

[0045] (1) for figure 2 The natural fracture sample shown has an estimated length of 172 mm and a width of 105 mm. As used in this example image 3 The FDM35-2525 3D printer shown can make casting molds with a maximum length and width of 250 mm and a maximum height of 350 mm, and the size of natural fracture rock samples is within the range allowed by the 3D printer. The length and width of the artificial experimental samples required for the experiment in this embodiment are both 50 mm, and the height is required to be about 50 mm. Therefore, it is onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com