Heat pipe type impinging stream grain dryer

A grain dryer and collision flow technology, applied in the direction of dryers, drying, drying chambers/containers, etc., can solve problems such as uneven temperature and humidity, uneven temperature field, large steel consumption, etc., to achieve The temperature field is uniform, the drying effect is excellent, and the effect of less structural steel is used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail

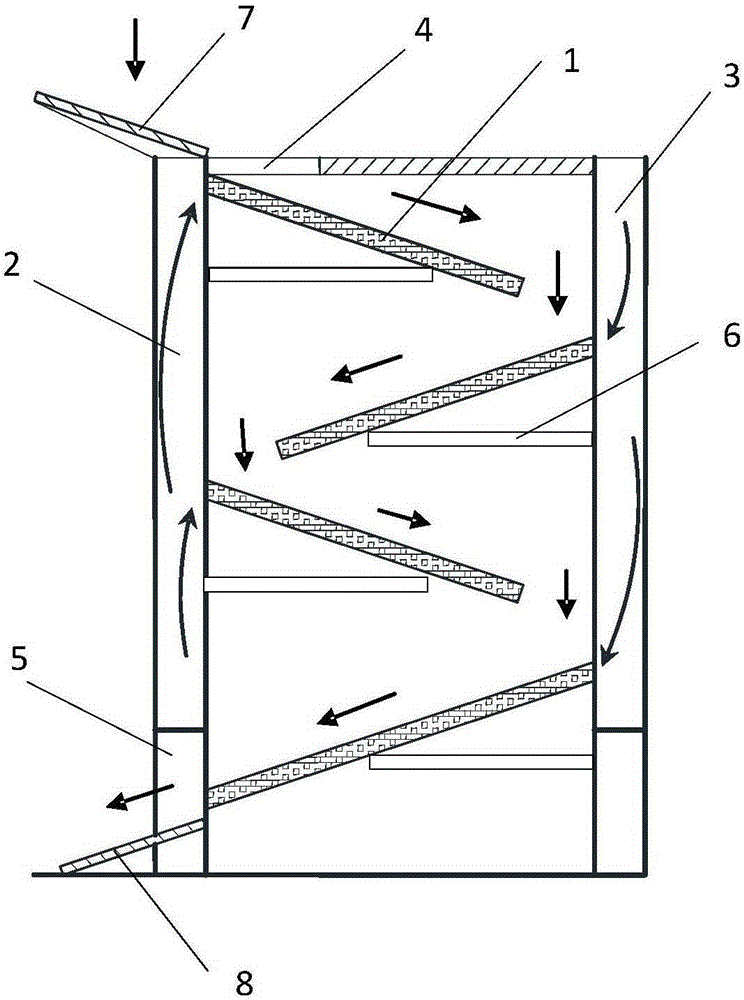

[0039]The heat pipe type collision flow grain dryer of the present invention adopts the new principle of collision flow drying, the hot air flows upward and the grain flows downward to form a collision flow. The arranged wind field produces the best drying effect on the passing grain, and the temperature field is more uniform and efficient. Utilizing the principle of impinging flow drying, the grain can make full use of the path during the traveling process, and the dryer can be more compact due to the baptism of the uniform wind field. Grain falls by gravity, which saves the motor and chain transmission mechanism, and saves mechanical parts.

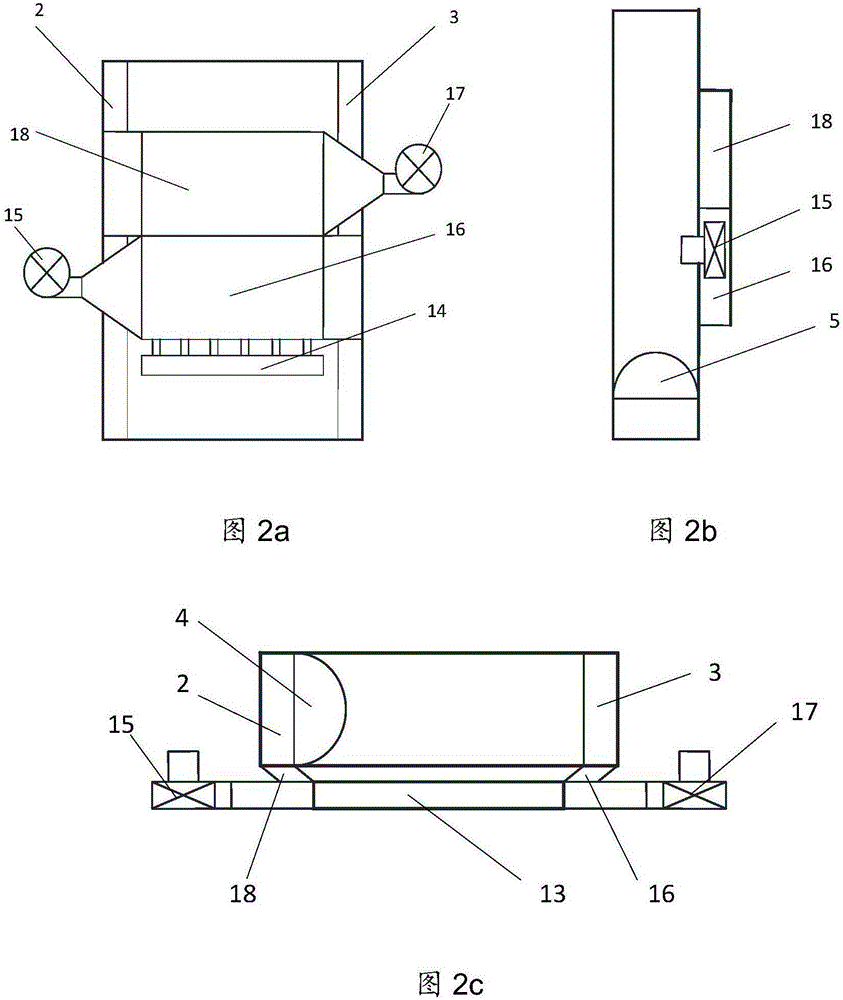

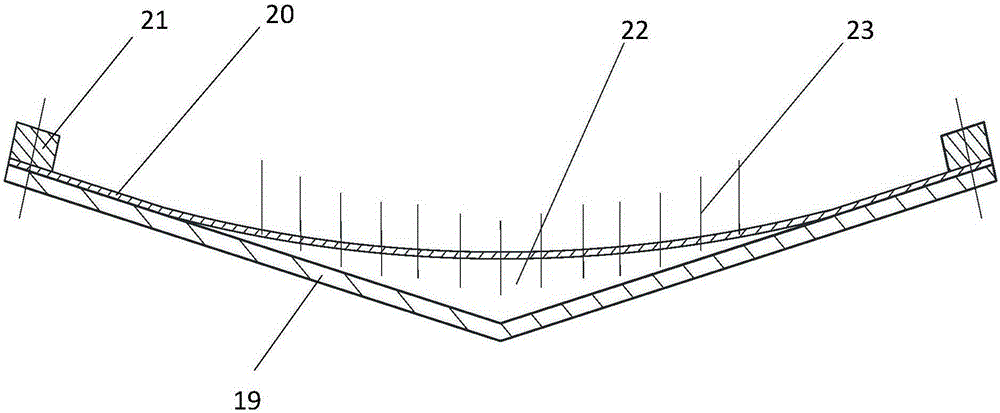

[0040] The drying machine of the present invention includes a material inlet, a material outlet, a slideway, an air chamber, a heat pipe heat exchanger, an air duct and a fan, and the slideway includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com