Anti-sedimentation joint structure of buried heat preservation steel pipes and construction method of anti-sedimentation joint structure

A joint structure and construction method technology, which is applied in the direction of pipes/pipe joints/fittings, heat preservation, and protection of pipes through heat insulation. and other issues, to achieve the effect of improving building construction quality, prolonging service life and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

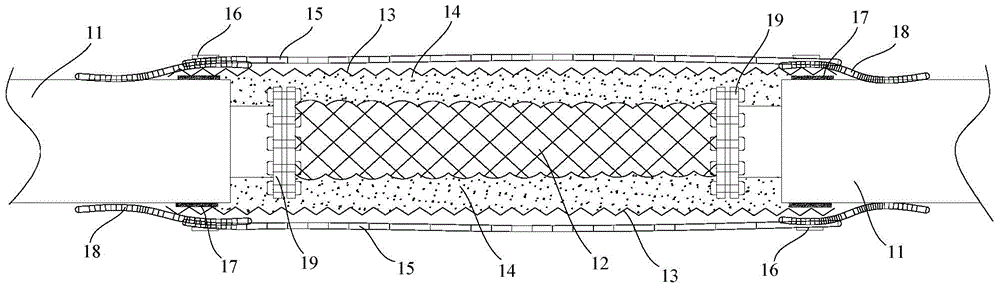

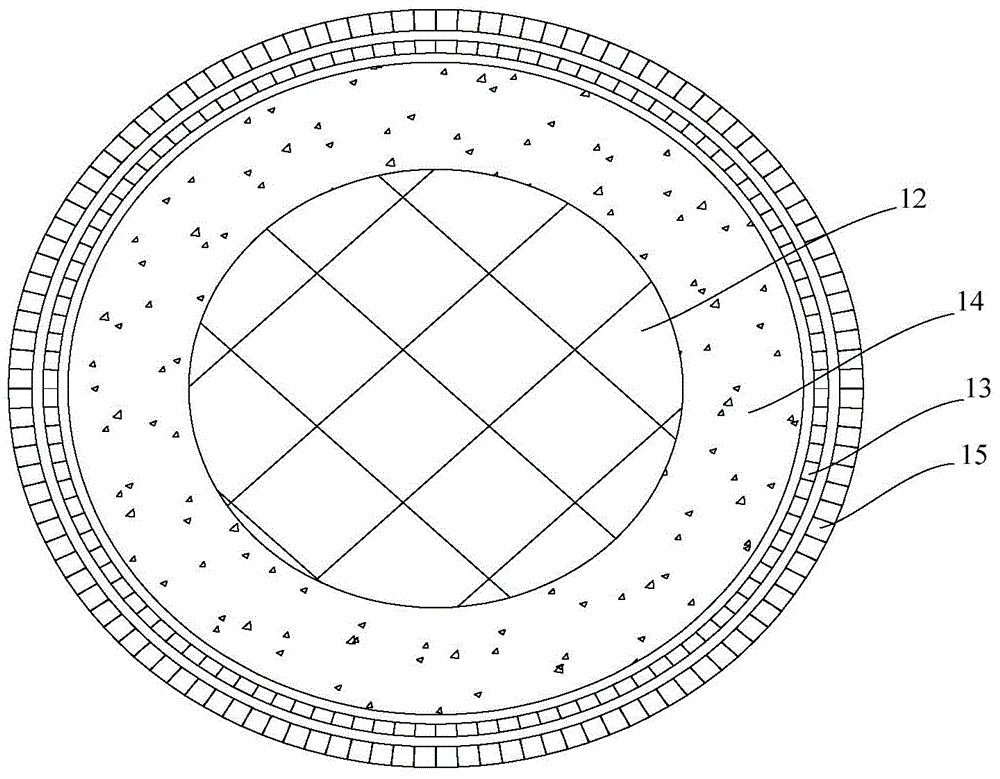

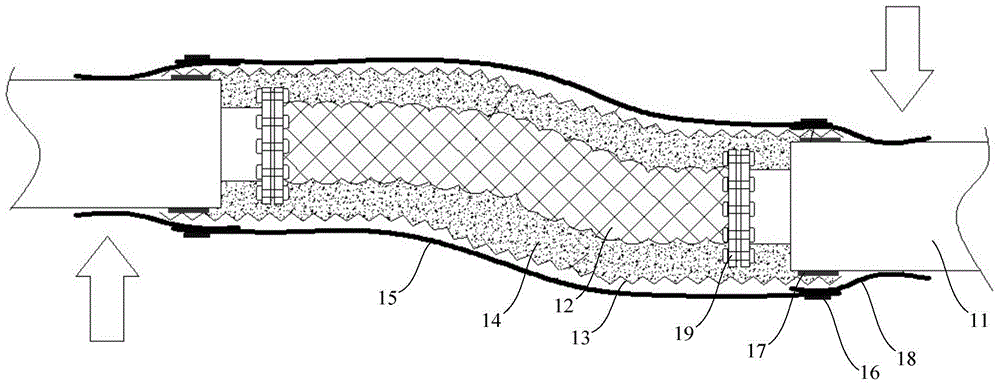

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] The invention provides an anti-subsidence joint structure of buried thermal insulation steel pipes and a construction method thereof. The anti-subsidence joint structure not only has the function of absorbing building subsidence, but also has the function of heat preservation and waterproof, reduces energy loss, and prolongs the service life of the product , Improve the quality of building construction. Wrapping glass wool on the outside of the anti-sedimentation pipe plays a role of thermal insulation for the anti-settling joint; a bendable water-proof stainless steel bellows is arranged on the outside of the glass wool, and the bellows plays a waterproof role. The bellows has a certain rigidity, which can prevent the glass wool from being compressed and protect the glass wool. Wrap the waterproof heat-shrinkable sleeve outside the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com