Floating oil passing pipe supporting structure for integrated type hydraulic servo mechanism

A technology of hydraulic servo and support structure, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of seal failure, external leakage, oil leakage, etc., to improve the sealing reliability , Prevent external leakage, eliminate the effect of not easy to seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

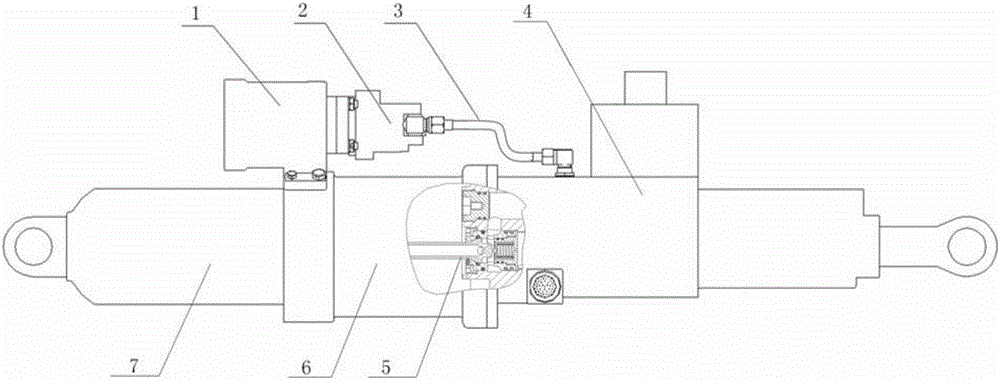

[0018] Such as figure 1 The installation layout of the integrated hydraulic servo mechanism and high-pressure floating oil pipe shown: the hydraulic servo mechanism includes a fuel tank 6, an accumulator 7, and an actuator 4, and the servo mechanism fuel tank 6 carries an electric pump, which includes an intermediate frequency motor 1 and a hydraulic pump 2. The high-pressure oil at the outlet of the hydraulic pump is introduced into the actuator 4 through the high-pressure oil pipe 3, and the high-pressure oil is directly introduced into the accumulator 7 from the actuator 4 by using the floating high-pressure oil pipe 5.

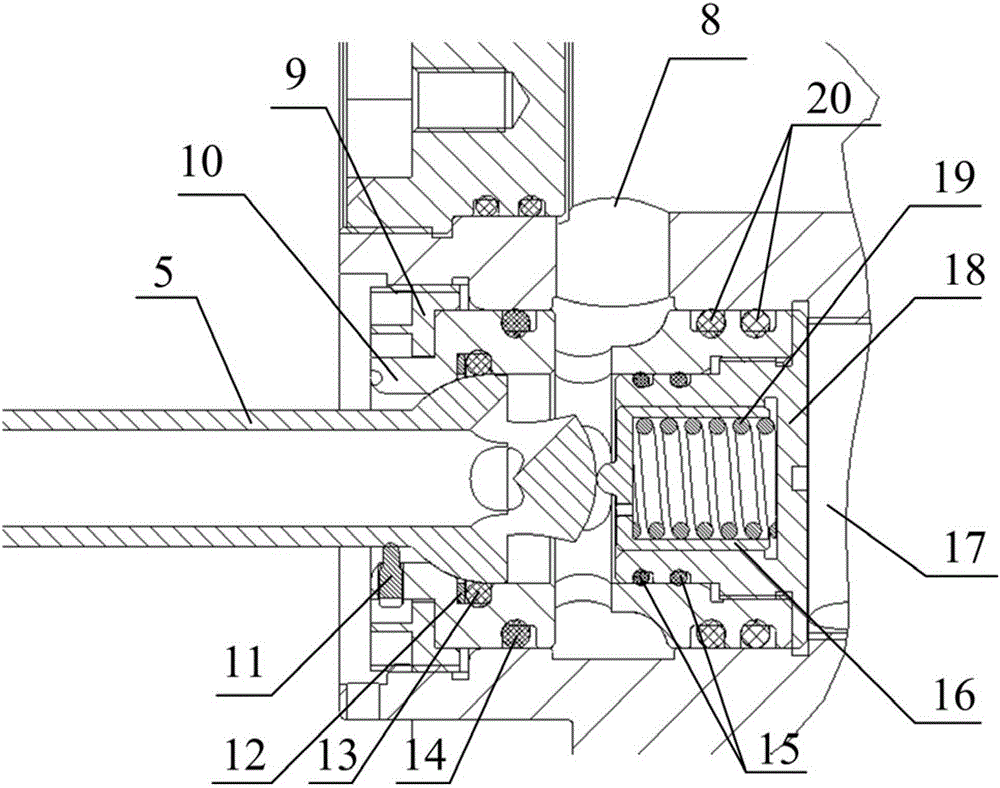

[0019] Such as figure 2 The floating oil pipe support structure for the integrated hydraulic servo mechanism shown includes an oil pipe 5, a support seat 10, a nut 9, a spring seat 18, a spring guide sleeve 16, a spring 19, a first sealing ring 13, and a second sealing ring 14 , the first double redundant structure 15 , the second double redundant struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com