Motor and connection structure of end covers and bearings thereof

A connection structure and bearing technology, applied in the direction of casing/cover/support, electromechanical device, electrical components, etc., can solve the problems of motor noise and vibration, deformation of bearing inner hole, motor stuck in operation, etc., to reduce working noise and Vibration, ensure coaxiality, avoid the effect of stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

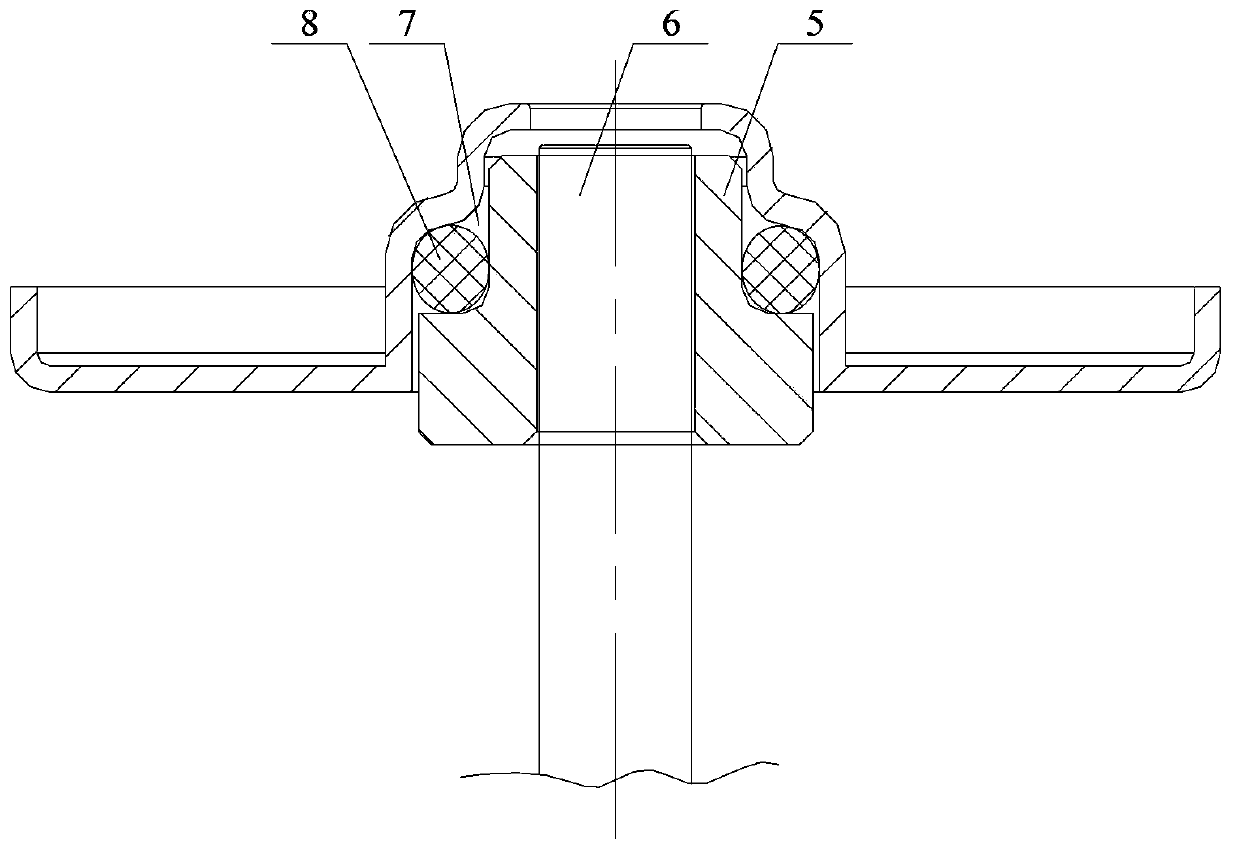

[0033] Please also see image 3 , which shows a schematic diagram of a connection structure between a bearing and an end cover.

[0034] In this solution, the radial cross-sections of the bearing cavity on the bearing 5 and the end cover are all in the shape of an inverted "T" shape with a small upper part and a larger lower part, and the steps on the bearing 5 are located below the steps on the inner wall of the bearing cavity; the aforementioned The annular accommodation portion 7 for accommodating the elastic support member 8 is formed between the small diameter section of the bearing 5 and the large diameter section of the bearing cavity between the two steps.

[0035] Here, the elastic support member 8 is preferably made of rubber material, which can meet the requirements of load bearing and self-adaptive deformation on the one hand, and at the same time, the manufacturing cost is controllable. The elastic support member 8 can be designed according to the external dimens...

Embodiment 2

[0039] See Figure 4 , which is a schematic diagram of the connection structure between the bearing and the end cover in the second embodiment. In order to clearly show the difference between this embodiment and the first embodiment, the same components are marked with the same symbols. The following examples are the same.

[0040] In this solution, the radial sections of the bearing 5 and the bearing cavity are both in the shape of a "T" shaped step with a large upper part and a smaller lower part, and the step on the bearing 5 is located above the step of the bearing cavity; the aforementioned is used to accommodate the elastic support The annular housing portion 7 of the member 8 is formed between the small diameter section of the bearing 5 and the large diameter section of the bearing cavity between the two steps.

Embodiment 3

[0043] See Figure 5 , which is a schematic diagram of the connection structure between the bearing and the end cover described in the third embodiment.

[0044] In this solution, the radial section of the bearing 5 is in the shape of "I"; the aforementioned annular accommodation part 7 for accommodating the elastic support 8 is formed on the outer surface of the bearing 5 in the "I"-shaped recess and the bearing cavity between the cylindrical inner walls.

[0045] Compared with the first and second embodiments, when the O-ring is used as the elastic support member 8, it is fitted in the inner recess of the outer surface of the bearing 5, and the relative position of the two will not be shifted axially, and the assembly operation is facilitated .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com