Electric parking brake (EPB) control method for electric car

An electronic parking and control method technology, applied in the direction of brakes, vehicle components, brake transmission devices, etc., can solve the problems of small parking effect, easy to reverse, abnormal noise, etc., to improve reliability and avoid stuck phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The EPB parking system used in the present invention is a parking device that utilizes frictional force to compress the wheel or the rotating shaft of the wheel, such as brake pads, brake shoes, mechanical calipers and the like.

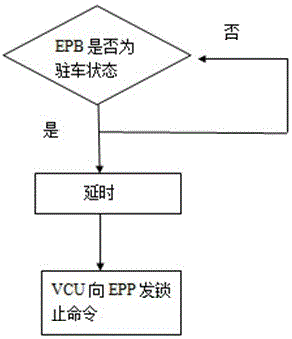

[0020] Such as figure 1 As shown, an electric vehicle electronic parking control method, the vehicle includes two sets of parking control systems EPB and EPP, the EPB parking system and the EPP parking system are controlled by the vehicle controller, and the delay time is set Afterwards, the following control is carried out. In the present invention, preferably, the delay time is 0.5 to 2 seconds;

[0021] In this embodiment, the delay time is set to 0.5 seconds, specifically divided into the following two situations:

[0022] Such as figure 2 As shown, from the driving state to the parking lock state, that is, when the vehicle is in P gear, the EPB parking system is used to lock the vehicle first, with a delay of 0.5 seconds, and the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com