Steel plate energy-dissipating wall with internally reinforced steel cylinders

A technology for strengthening steel plates and steel cylinders, which is applied to walls, building components, and shockproofing, etc., can solve problems such as unfavorable energy consumption and concentrated plastic distribution of energy-consuming steel plate walls, and achieve strong energy dissipation capacity, large lateral stiffness, and improved The effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

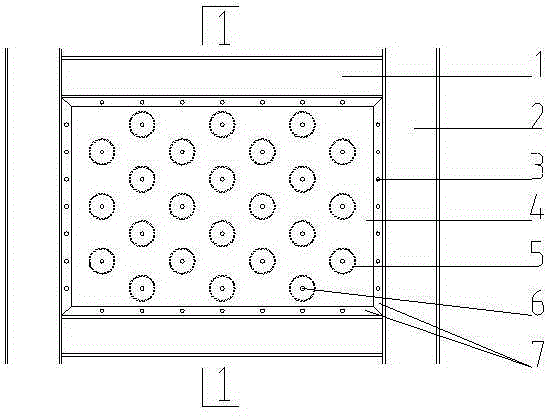

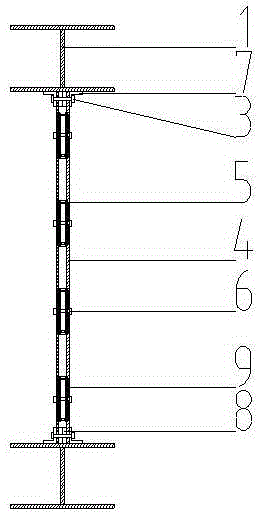

[0016] The reinforced steel plate energy-dissipating wall in the steel cylinder proposed by the present invention is as follows: figure 1 , figure 2 shown.

[0017] The whole device is composed of steel beam 1, steel column 2, energy-dissipating steel plate 4, inner reinforced steel cylinder 5, outer corner plate 7, inner backing plate 8, hard rubber non-adhesive layer 9.

[0018] First, determine the size of the energy-dissipating steel plate 4 and the arrangement and quantity of the inner reinforcing steel cylinder 5, that is, the position and quantity of the screw holes of the restraining bolts 6, according to the actual situation of the project. Determine the size of the inner backing plate 8 and the outer corner plate 7 according to the size of the energy-dissipating steel plate 4 and the height of the inner reinforci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com