Denim printing and dyeing method

A technology of denim and printing and dyeing auxiliaries, which is applied in the field of printing and dyeing, can solve the problem of high steaming temperature, and achieve the effect of not easy to fade and fast color fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

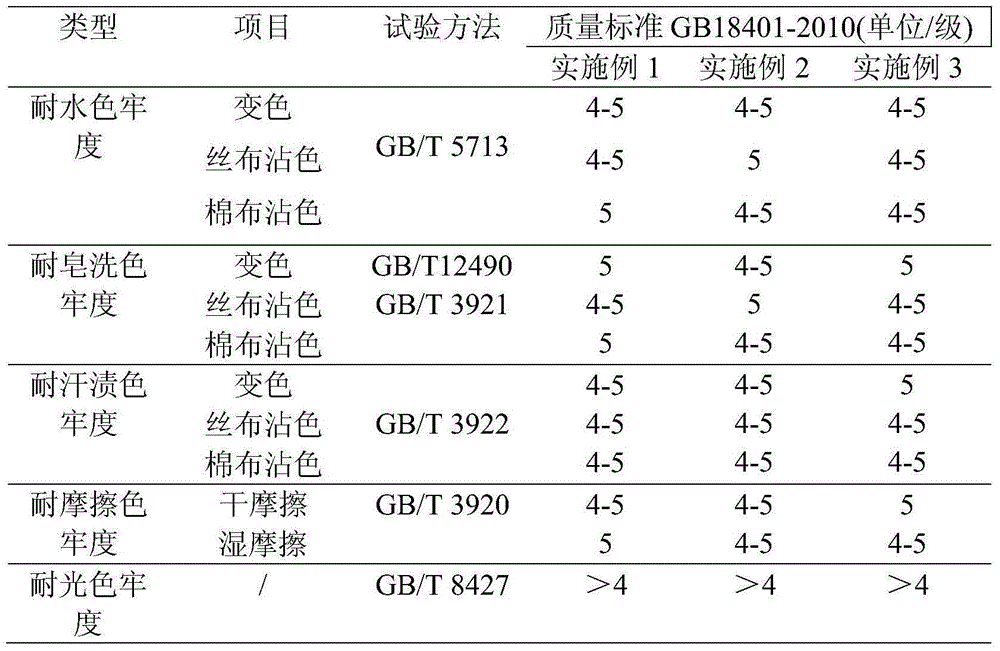

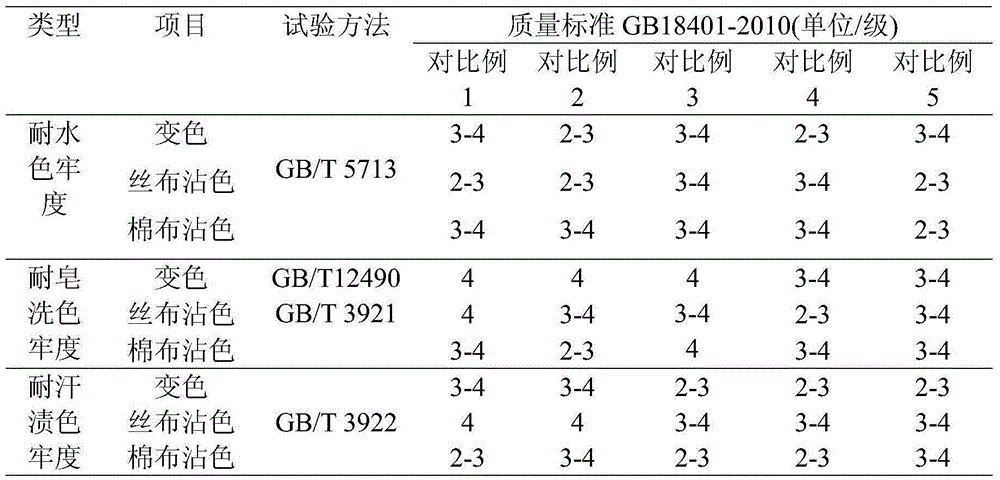

Examples

Embodiment 1

[0032] Carry out denim printing and dyeing through the following steps in the present embodiment:

[0033] (1) Preparation of printing and dyeing paste: get 30 parts by weight of etherified starch paste, 9 parts by weight of sodium carbonate, 3 parts by weight of white powder, 15 parts by weight of glycerin, 10 parts by weight of indigo vat dyes and 22 parts by weight of deionized water to prepare A Part of printing paste; get 8 parts by weight of glycerin, 30 parts by weight of sodium carbonate, deionized water of 13 parts by weight, starch paste of 70 parts by weight, 15 parts of carved white powder and 3 parts by weight of sulfur dyes to prepare B part of printing paste; Mix parts A by weight of printing paste and 50 parts by weight of B printing paste, add 5 parts by weight of printing and dyeing auxiliaries to make printing and dyeing paste, and control its viscosity at 13000-15000 Pa·S. Net filter, and then filter with 60 mesh screen;

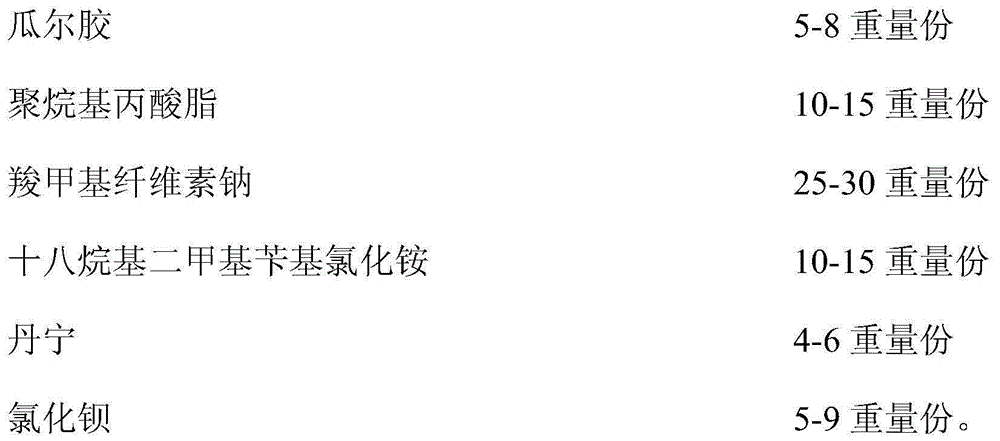

[0034] Wherein the preparation of...

Embodiment 2

[0040] Carry out denim printing and dyeing through the following steps in the present embodiment:

[0041] (1) Preparation of printing and dyeing paste: get 35 parts by weight of etherified starch paste, 10 parts by weight of sodium carbonate, 4 parts by weight of white powder, 12 parts by weight of glycerin, 13 parts by weight of indigo vat dyes and 15 parts by weight of deionized water to prepare A Part of printing paste; get 5 parts of glycerin, 28 parts of sodium carbonate, 9 parts of deionized water, 65 parts of starch paste, 10 parts of carved white powder and 1 part of sulfur dye to prepare B part of printing paste; Part A of the printing paste by weight is mixed with 50 parts of the printing paste of B by weight, and 8 parts by weight of the printing and dyeing auxiliary agent are added to make a printing and dyeing paste. The viscosity is controlled at 13000-15000 Pa·S. Mesh screen filter, and then filter with 60 mesh screen;

[0042]The preparation of the printing a...

Embodiment 3

[0048] In this embodiment, the denim printing and dyeing is carried out by the following steps:

[0049] (1) Preparation of printing and dyeing slurry: get 32 parts by weight of etherified starch slurry, 8 parts by weight of sodium carbonate, 3 parts by weight of cartilage powder, 18 parts by weight of glycerin, 15 parts by weight of indigo vat dyes, 18 parts by weight of deionized water to prepare A Part of printing paste; get 7 parts by weight of glycerin, 25 parts by weight of sodium carbonate and 15 parts by weight of deionized water, 60 parts by weight of starch pulp, 12 parts by weight of white powder and 2 parts by weight of sulfur dyes to prepare B parts of printing paste; 50 parts by weight of printing paste; A part by weight of printing paste is mixed with 50 parts by weight of B part of printing paste, and 10 parts by weight of printing and dyeing auxiliaries are added to make printing and dyeing paste. Mesh filter, and then filter with 60 mesh wire mesh;

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com