Preparation method of single-layer graphene oxide modified waterborne polyurethane composite material

A water-based polyurethane and graphene modification technology is applied in the field of preparation of single-layer graphene oxide modified water-based polyurethane composite materials, which can solve the problems of thick GO layers, difficulty in exerting graphene oxide properties, and easy agglomeration. The effect of mechanical advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

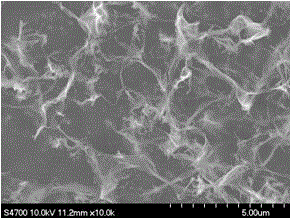

[0027] (1) Preparation of single-layer graphene oxide: using a new type of iron-based strengthening agent, potassium ferrate, to oxidize and exfoliate flake graphite. Take flake graphite with a particle size of 40 μm and 98% concentrated sulfuric acid and stir, mix and infiltrate at -10°C for 0.5h , Potassium ferrate and periodic acid were added, and then the reaction solution was raised to 0° C. for 1 h. After the reaction, the reaction solution was centrifuged at 4000r / min to discard the strong acid. Slowly pour the sediment at the bottom into deionized water at 2°C to dilute, let it stand still for 0.5h, wash the sediment repeatedly with 1mol / L dilute hydrochloric acid and deionized water, wash each 15 times in turn, and centrifuge until the centrifuged supernatant The pH value was close to 7, and the final product was freeze-dried at -40°C for 48 hours to obtain a single-layer graphene oxide. During the reaction, the ratio of strong acid to graphite is 10mL: 1g, and the r...

Embodiment 2

[0034] (1) Preparation of single-layer graphene oxide: using a new type of iron-based strong oxidant, potassium ferrate, to oxidize and exfoliate flake graphite, take flake graphite with a particle size of 10 μm and 98% concentrated sulfuric acid and stir, mix and infiltrate at -10°C for 0.5h , Potassium ferrate and periodic acid were added, and then the reaction solution was raised to 0° C. for 1 h. After the reaction, the reaction solution was centrifuged at 4000r / min to discard the strong acid. Slowly pour the sediment at the bottom into deionized water at 5°C to dilute, let stand for 0.5h, wash the sediment repeatedly with 1mol / L dilute hydrochloric acid and deionized water, wash each 15 times in turn, and centrifuge until the centrifuged supernatant The pH value was close to 7, and the final product-50 was freeze-dried for 48 h to obtain a single-layer graphene oxide. During the reaction, the ratio of strong acid to graphite is 50mL: 1g, and the ratio of potassium ferrat...

Embodiment 3

[0039] (1) Preparation of single-layer graphene oxide: using a new type of iron-based strong oxidant, potassium ferrate, to oxidize and exfoliate flake graphite, take flake graphite with a particle size of 40 μm and 98% concentrated sulfuric acid and stir, mix and infiltrate at -10°C for 0.5h , Potassium ferrate and perchloric acid were added, and then the reaction solution was raised to 0° C. for 1 h. After the reaction, the reaction solution was centrifuged at 4000r / min to discard the strong acid. Slowly pour the sediment at the bottom into deionized water at 10°C to dilute, let stand for 0.5h, wash the sediment repeatedly with 1mol / L dilute hydrochloric acid and deionized water, wash each 15 times in turn, and centrifuge until the centrifuged supernatant The pH value was close to 7, and the final product was freeze-dried at -30°C for 48 hours to obtain a single-layer graphene oxide. During the reaction, the ratio of strong acid to graphite is 80mL: 1g, and the ratio of pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com