Limestone water-containing layer grouting reconstruction material suitable for superlong-distance pumping

A distance and pumping technology, applied in the field of material science, can solve the problems of difficult to achieve long-distance transportation, the influence of water glass temperature, and easy to block the grouting pipe, so as to achieve high-efficiency utilization, improve density, improve slurry and ease of use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] 1. Components and mass ratio: 68 parts of coal gangue, 20 parts of sulphoaluminate cement clinker, 12 parts of steel slag micropowder, and 9.5 parts of composite active initiator. Active initiator components and mass ratio are: 17 parts of alum, 24 parts of talcum powder, 11 parts of guar gum, 6 parts of hydroxypropyl methylcellulose, and 42 parts of gypsum powder.

[0031] 2. Preparation method: coal gangue and sulphoaluminate cement clinker grinding fineness 385m 2 / kg, according to the water-cement ratio 1.2:1, mix and stir evenly.

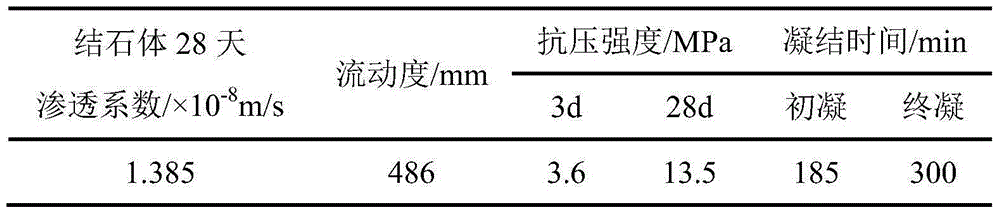

[0032] 3. The index parameters are as follows in Table 1:

[0033] Table 1

[0034]

[0035] The grouting reconstruction material prepared above was used to transform the limestone aquifer of the coal seam floor, and the long-distance pumping from the ground to the buried depth of -960 meters was realized, and the ambient temperature difference was 20°C, effectively transforming the aquifer into an aquifer .

specific Embodiment 2

[0037] 1. Components and mass ratio: 68 parts of coal gangue, 20 parts of sulphoaluminate cement clinker, 12 parts of steel slag micropowder, and 9.5 parts of composite active initiator. Active initiator components and mass ratio are: 14 parts of alum, 20 parts of talcum powder, 9 parts of guar gum, 8 parts of hydroxypropyl methylcellulose, and 46 parts of gypsum powder.

[0038] 2. Preparation method: coal gangue and sulphoaluminate cement clinker grinding fineness 383m 2 / kg, according to the water-cement ratio 1.2:1, mix and stir evenly.

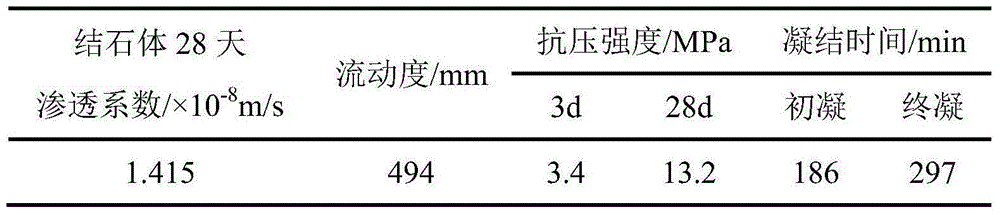

[0039] 3. The index parameters are as follows in Table 2:

[0040] Table 2

[0041]

[0042] The grouting reconstruction material prepared above was used in the grouting reconstruction of the aquifer of the tunnel floor. The stone body formed after the grout injection has high strength and good impermeability. Pulp management effect.

specific Embodiment 3

[0044] 1. Components and mass ratio: 66 parts of coal gangue, 24 parts of sulphoaluminate cement clinker, 10 parts of steel slag micropowder, and 11 parts of composite active initiator. Active initiator components and mass ratio are: 17 parts of alum, 24 parts of talcum powder, 11 parts of guar gum, 6 parts of hydroxypropyl methylcellulose, and 42 parts of gypsum powder.

[0045] 2. Preparation method: coal gangue and sulphoaluminate cement clinker grinding fineness 395m 2 / kg, according to the water-cement ratio 1.2:1, mix and stir evenly.

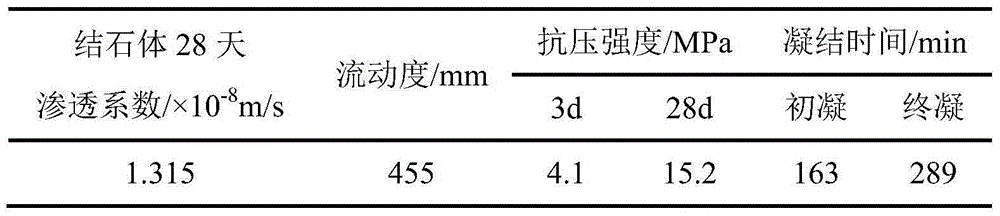

[0046] 3. The index parameters are as follows in Table 3:

[0047] table 3

[0048]

[0049] The grouting reconstruction material prepared above is used for the grouting reconstruction of the floor aquifers of subways, etc., and the stone body formed after the grout injection has high strength, which has a good effect of grouting treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com