Method for reinforcing recycled concrete fine aggregate by using carbon dioxide

A technology of recycled concrete and recycled fine aggregate, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of limited strength improvement, low content of carbonizable substances, limited effect, etc., to reduce Aggregate crushing value, reduction of aggregate water absorption, and improvement of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] (1)Ca(OH) 2 Solution treatment: spread the regenerated fine aggregate on the tray, and spray Ca(OH) whose parameter C is 0.01mol / kg 2 aqueous solution and stir evenly, and control its water content to 5%.

[0029] (2) CO 2 Strengthening treatment: will be treated with Ca(OH) 2 The regenerated fine aggregate after aqueous solution treatment was placed in a closed carbonization box, the temperature was controlled at 30°C, the relative humidity was 50%, and the CO 2 The concentration is 75%, carbonization treatment until the surface carbonization is complete.

[0030] (3) Preparation of recycled mortar: the recycled mortar with a substitution rate of 100% was prepared by using the treated recycled fine aggregate.

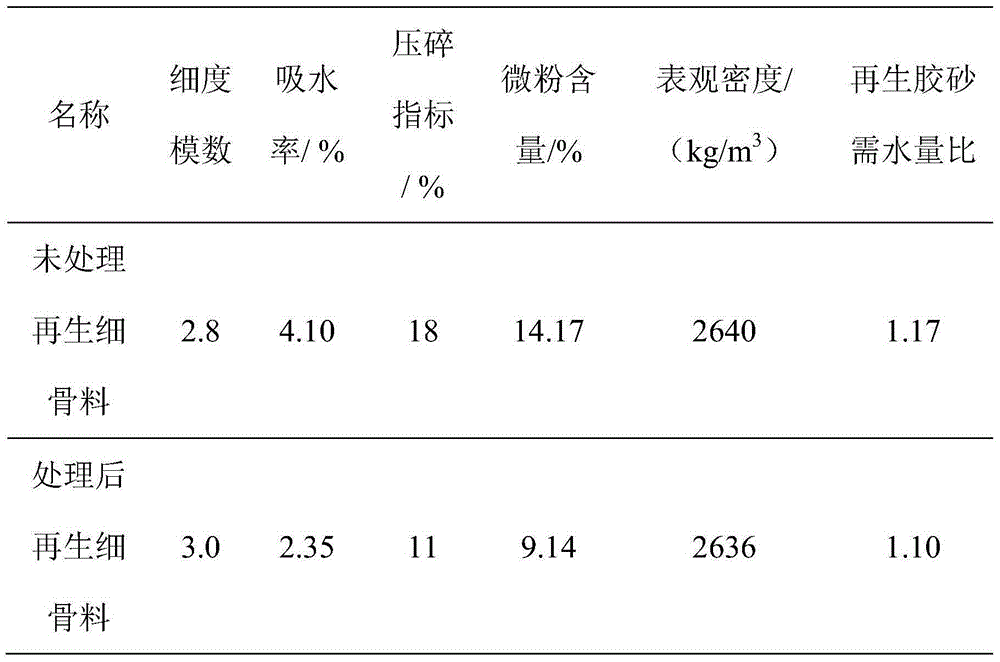

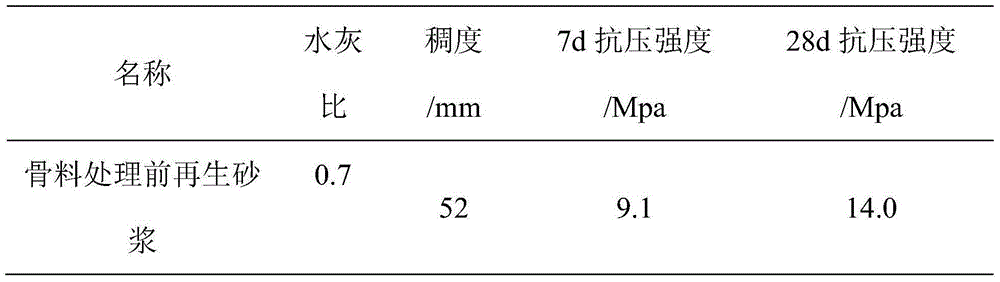

[0031] Refer to the standard GB / T25176-2010 "Recycled Fine Aggregate for Concrete and Mortar" and GB / T14684-2011 "Sand for Construction" to investigate the basic properties of aggregates before and afte...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] (1)Ca(OH) 2 Solution treatment: spread the recycled fine aggregate on the tray, and spray Ca(OH) whose parameter C is 0.05mol / kg 2 aqueous solution and stir evenly, and control its water content to 0.2%.

[0041] (2) CO 2 Strengthening treatment: will be treated with Ca(OH) 2 The regenerated fine aggregate after aqueous solution treatment was placed in a closed carbonization box, and the temperature was controlled at 10 °C, CO 2 The concentration is 100%, carbonization treatment until the surface carbonization is complete.

[0042] (3) Preparation of recycled mortar: the recycled mortar with a substitution rate of 100% was prepared by using the treated recycled fine aggregate.

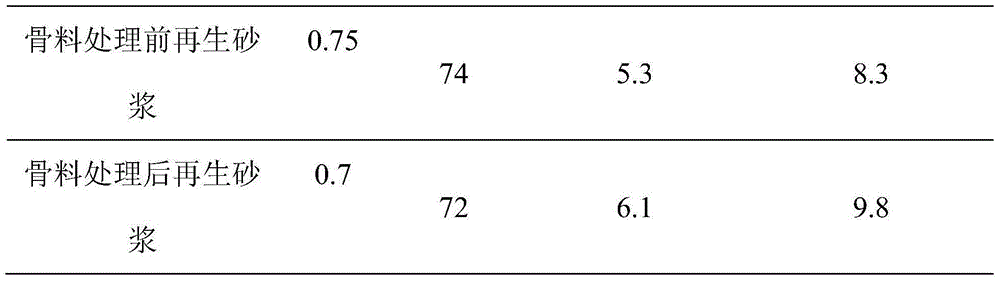

[0043] The results show that carbonation treatment after adding calcium can effectively reduce the water absorption and crushing value indicators of recycled concrete fine aggregate, as shown in Table 3.

[0044] Table 3 Properties of ...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] (1) Calcium chloride solution treatment: spread the regenerated fine aggregate on the tray, spray the calcium chloride aqueous solution whose parameter C is 0.01mol / kg and stir evenly, and control the moisture content of the regenerated aggregate to 10%.

[0052] (2) CO 2 Strengthening treatment: put the regenerated fine aggregate treated with calcium chloride aqueous solution in a closed carbonization box, control the temperature at 50°C, relative humidity at 20%, CO 2 The concentration is 20%, carbonization treatment until the surface carbonization is complete.

[0053] (3) Preparation of recycled mortar: the recycled mortar with a substitution rate of 100% was prepared by using the treated recycled fine aggregate. As shown in Table 5.

[0054] Table 5 Properties of recycled aggregate before and after carbonization

[0055]

[0056] The CO obtained in this example 2 The recycled concrete aggregate after st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com