Composite efficient low-phosphorus corrosion-inhibiting and scale-inhibiting agent for low hardness water, and preparation method thereof

A technology of corrosion and scale inhibition, low hardness, applied in chemical instruments and methods, complex/solubilizer treatment, scale removal and water softening, etc., can solve the problems of water eutrophication, high total phosphorus content, and polluted water , to achieve the effect of stable performance, good stability and easy compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: test raw water water quality is: PH7.78, Cond179 μ s / cm, total calcium hardness 90mg / L (as CaCO 3 Calcium hardness 50mg / L (calculated as CaCO 3 count), Cl - 60mg / L, total alkalinity 80mg / L (as CaCO 3 count).

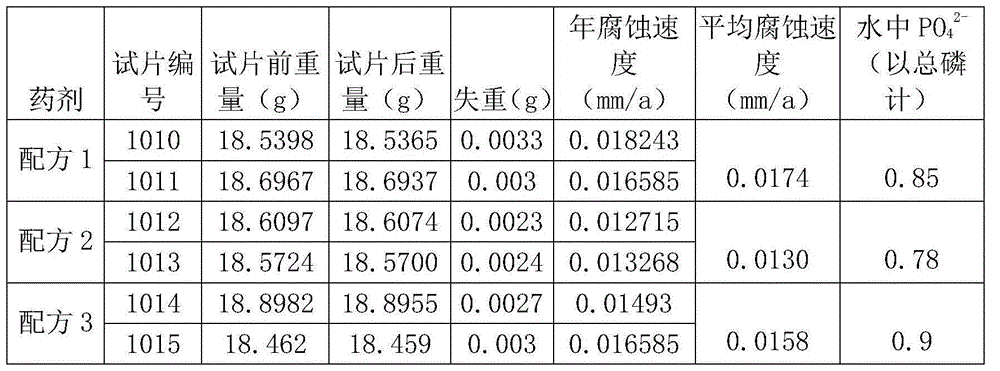

[0034] According to the test raw water quality of 2.5 times of concentration, the experiment was carried out, and the calcium hardness 125mg / L (as CaCO 3 count), Cl - 150mg / L, total alkalinity 200mg / L (as CaCO 3 The water temperature is 40°C, each compound agent is added at 30mg / L, and the test is carried out according to the standard "Determination of Corrosion and Scale Inhibition Performance of Water Treatment Agents--Rotary Hanging Plate Method" (GB-T18175-2000), the test results are as follows .

[0035]

[0036] According to the experiment, the corrosion rate of the carbon steel coupon meets the requirements of the industrial circulating cooling water treatment design specification (GB50050--2007) at the concentration of 2.5 times. 4 ...

Embodiment 2

[0038] The raw water quality of the test is: PH7.82, Cond140μs / cm, total calcium hardness 60mg / L (calculated as CaCO 3 Calcium hardness 40mg / L (calculated as CaCO 3 count), Cl - 35mg / L, total alkalinity 61mg / L (as CaCO 3 count).

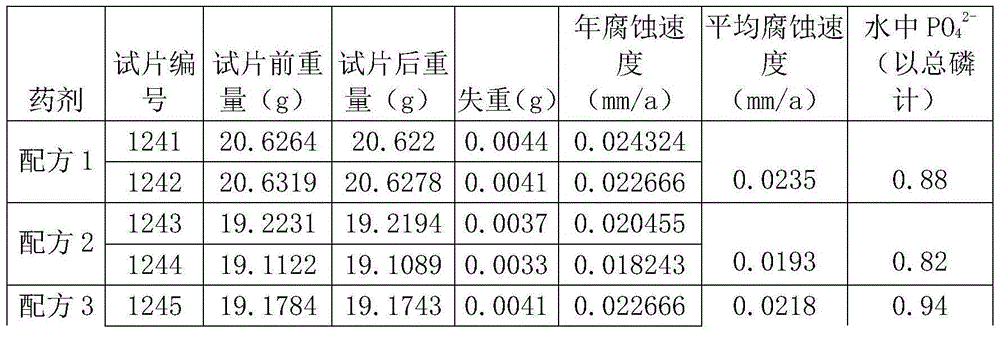

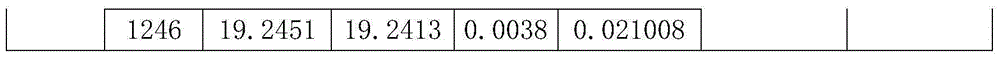

[0039] According to the test raw water quality of 5 times of concentration, the experiment was carried out, and the calcium hardness was prepared to be 300mg / L (in the form of CaCO 3 count), Cl - 175mg / L, total alkalinity 305mg / L (as CaCO 3 meter), the water temperature is 40°C, each compound agent is added at 30mg / L, and the test is carried out according to the standard of "Determination of Corrosion and Scale Inhibition Performance of Water Treatment Agents--Rotating Plate Method" (GB-T18175-2000), and the test results are as follows.

[0040]

[0041]

[0042] Experiments show that the corrosion rate of carbon steel coupons still meets the requirements of industrial circulating cooling water treatment design specifications (GB50050--200...

Embodiment 3

[0044] Formula 2 is selected and applied to a circulating water station of a factory, and the water volume of the system is 6800m 3 , the circulating water volume is 6500m 3 , the system water quality is: PH8.72, Cond877μs / cm, total calcium hardness 360mg / L (calculated as CaCO 3 Calcium hardness 280mg / L (calculated as CaCO 3 count), Cl - 155mg / L, total alkalinity 275mg / L (as CaCO 3 count). The dosage of composite low-phosphorus corrosion and scale inhibitors is 30mg / L, and after one month of operation, the corrosion rate of carbon steel coupons is 0.0203mm / a, and PO in circulating water 4 2- (calculated by total phosphorus) the total phosphorus detected every day is ≤1.0mg / L, and the system cooler has no carbonate scale deposition, which has achieved good application results.

[0045] A composite high-efficiency low-phosphorus corrosion and scale inhibitor suitable for low-hardness water of the present invention has the following advantages:

[0046] 1. There is a good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com