A preparation method of silver-based composite nanomaterial with surface-enhanced Raman activity and its products and applications

A technology of nanomaterials and silver-based composites, applied in nanostructure manufacturing, Raman scattering, nanotechnology, etc., can solve the problems of difficult to guarantee detection repeatability, shortened service life, high preparation cost, etc., achieving remarkable SERS effect and easy control , the effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

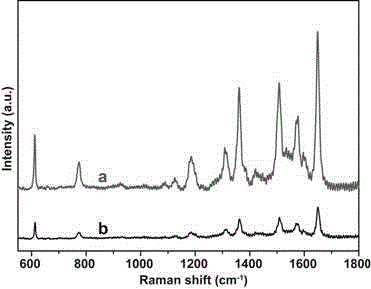

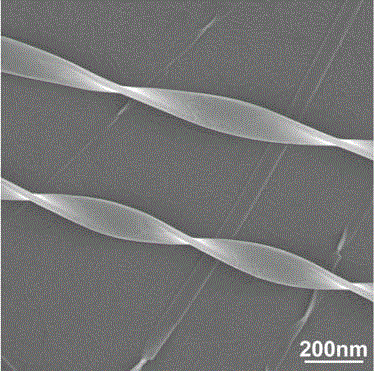

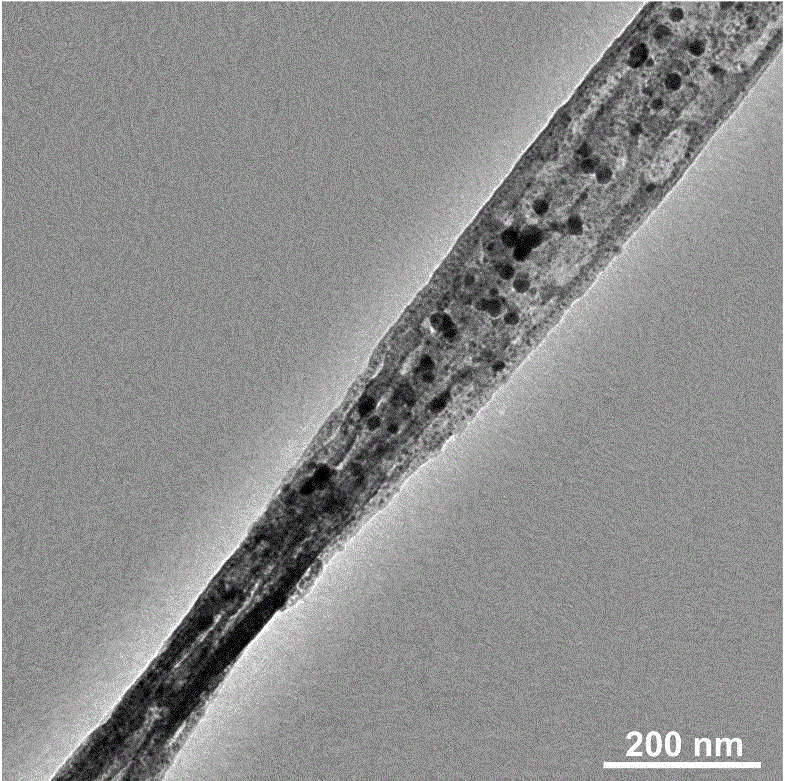

[0056] Weigh 160 mg of melamine and 68 mg of silver nitrate with an electronic analytical balance, and dissolve them in 55 mL and 5 mL of water, respectively. Then, the newly prepared silver nitrate solution was slowly added dropwise to the melamine aqueous solution under stirring at room temperature, and continued to stir for 30 minutes to obtain a white nearly gelatinous substance, and the supernatant was discarded by centrifugation to obtain an intermediate product. The obtained intermediate product is a solid one-dimensional helical nanoribbon, and its microscopic morphology is shown in figure 1 with figure 2 , the surface of the nanobelt is smooth, the length is submillimeter, the width is about 100 nm, and the thickness is about 40 nm.

[0057] The obtained intermediate product was re-dispersed ultrasonically with 5 mL of absolute ethanol, evenly drop-coated on a glass plate with a clean surface, and dried in an oven at 45 °C. After drying, the glass plate containing t...

Embodiment 2

[0059] Weigh 160 mg of melamine and 30 mg of silver nitrate with an electronic analytical balance, and dissolve them in 55 mL and 5 mL of water, respectively. Then, the newly prepared silver nitrate solution was slowly added dropwise to the melamine solution under stirring at room temperature, and continued to stir for 30 minutes to obtain a white nearly gelatinous substance, and the supernatant was discarded by centrifugation to obtain an intermediate product. The obtained intermediate product is a solid one-dimensional helical nanoribbon, and its microscopic morphology is shown in Figure 4 , the surface of the nanobelt is smooth, the width is 100-200 nm, the thickness is 30-50 nm, and the length is submillimeter.

[0060] The obtained intermediate product was re-dispersed ultrasonically with 3 mL of absolute ethanol, evenly drop-coated on a glass plate with a clean surface, and dried in an oven at 45 °C. After drying, the glass plate containing the intermediate product was ...

Embodiment 3

[0062] Weigh 160 mg of melamine and 48 mg of silver nitrate with an electronic analytical balance, and dissolve them in 55 mL and 5 mL of water, respectively. Then, slowly drop the newly configured silver nitrate solution into the melamine solution under stirring at room temperature, and continue to stir for 30 minutes to obtain a white and nearly gelatinous substance. The supernatant was discarded by centrifugation to obtain a solid one-dimensional helical nanoribbon. intermediate product, its microscopic appearance is shown in Image 6 , the surface of the nanobelt is smooth, the width is 50-200 nm, the thickness is 40-50 nm, and the length is submillimeter.

[0063] The obtained intermediate product was re-dispersed ultrasonically with 5 mL of absolute ethanol, evenly drop-coated on a glass plate with a clean surface, and dried in an oven at 45 °C. After drying, the glass plate containing the intermediate product was immersed in 0.5 mmol / L boron Sodium hydride aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com