Carrier device and inkjet printer having the same, and carrying method

An inkjet printer and conveying device technology, which is applied in the directions of printing device, transportation and packaging, printing, etc., can solve problems such as inability to perform transfer processing properly and transfer position deviation of printing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

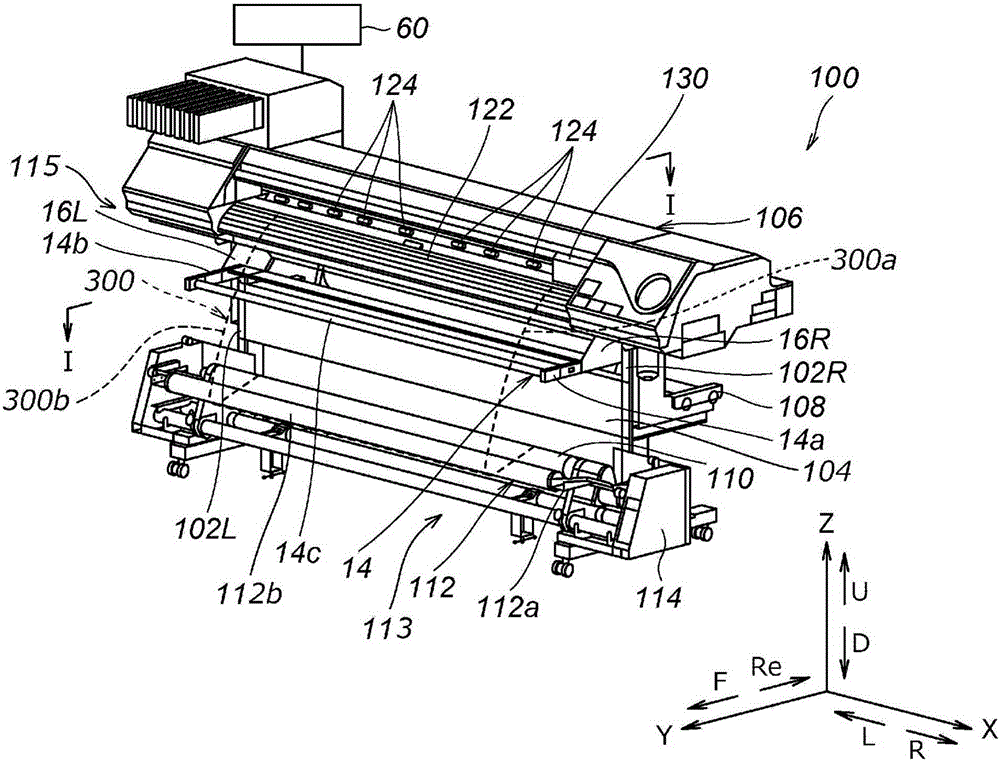

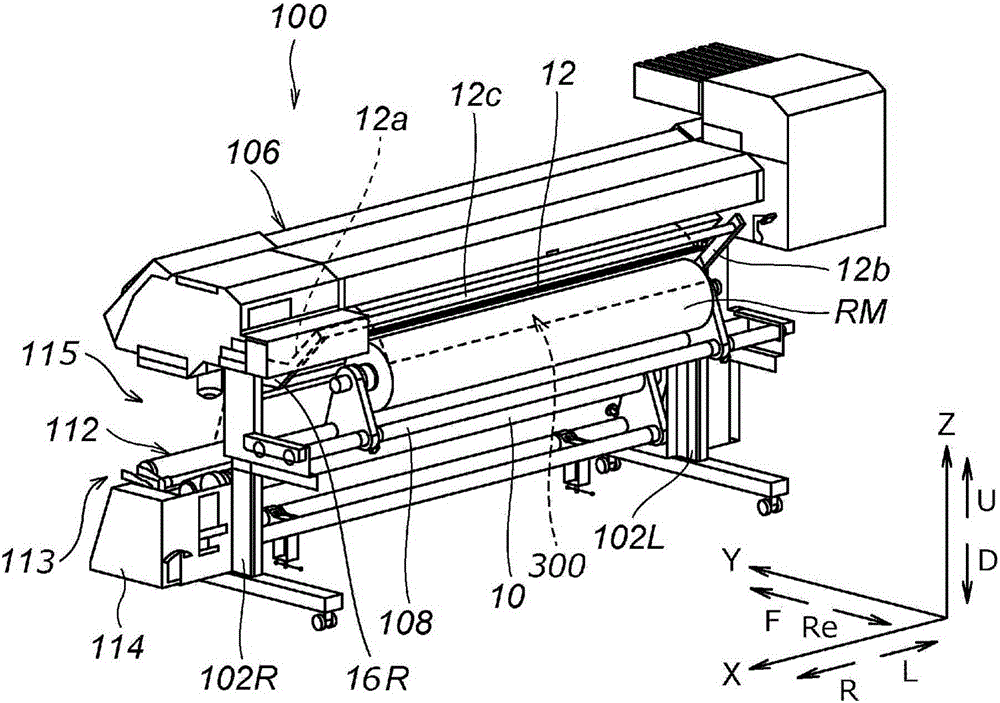

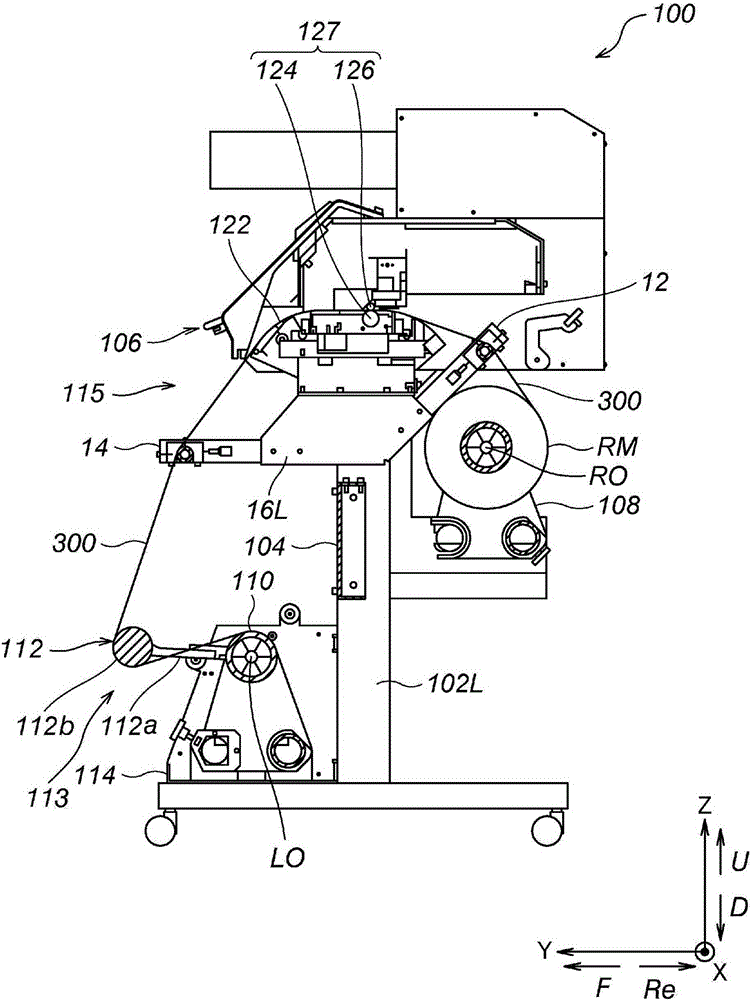

[0077] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a front perspective view showing the configuration of the inkjet printer 100 including the transport device 115 . figure 2 It is a rear perspective view showing the configuration of the inkjet printer 100 including the transport device 115 . image 3 Yes figure 1 The sectional view along the I-I line.

[0078] In this specification, "medium" includes paper such as plain paper, various recording media made of resin materials such as PVC and polyester, and various materials such as aluminum, iron, and wood.

[0079] In this specification, the width direction of the medium 300 is appropriately referred to as a "main scanning direction". Furthermore, the direction perpendicular to the main scanning direction is appropriately referred to as a "sub-scanning direction".

[0080] In this specification, "inkjet method" includes conventionally known inkjet pri...

no. 2 approach

[0164] like Figure 12 As shown, the inkjet printer 100 also includes a sensor 58 . The sensor 58 is provided on the left side of the ink head 130 . The sensor 58 moves in the X-axis direction together with the ink head 130 . The sensor 58 acquires an X-coordinate value of an end portion of the medium 300 on the platen 122 in the X-axis direction (main scanning direction) when the ink head 130 moves in the X-axis direction. In addition, the sensor 58 may also be disposed on the right side of the ink head 130 .

[0165] like Figure 13 As shown, the microcomputer 60 includes: a storage unit 62 for storing various data such as input print image data; a first print unit 64 for performing predetermined printing on the medium 300 based on the print image data; The second printing unit 66 for adjusting the scale of the medium 300 is printed using the setting value of the storage unit 62 .

[0166] The storage unit 62 stores various types of data, such as data for printing image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com