Automatic loading machine and process thereof

An automatic and technological technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as large deviation, mechanism wear, and inaccurate equipment operation, and achieve the effect of high precision, overcoming easy wear, and precise operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

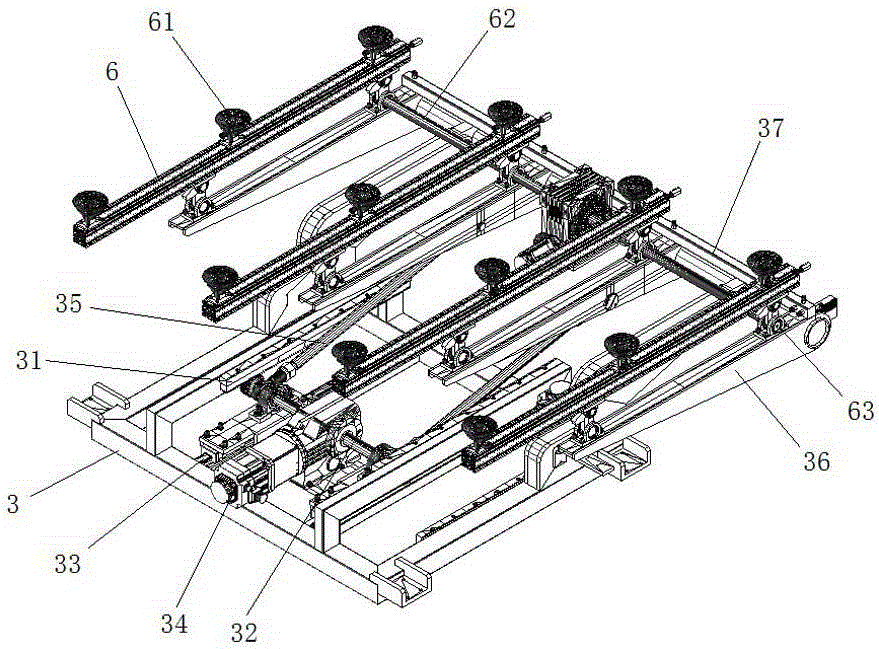

[0016] Embodiment one: if Figure 1~3 As shown, an automatic loading machine includes a frame 1, the bottom of the frame 1 is provided with a rail frame 2, and both sides of the rail frame 2 are provided with guide rails 21 that are guided along the front and rear, and on the rail frame 2 A base 3 that moves along the guide rail is provided, and a plurality of roller shafts 5 arranged along the left and right direction are evenly distributed on the upper part of the frame 1. The base 3 is provided with a slide rail 33 that is guided along the front and rear. 3 is provided with a base 4 that moves along the slide rail, and the base 4 is provided with a rotating shaft 32 that is driven by a motor 34 to rotate. The two sides of the base 3 are provided with racks 31 that are guided forward and backward. Both ends are provided with gears that engage with the rack 31, the two ends of the rotating shaft 32 are also hinged with connecting rods 35, the two sides of one end of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com