720 pipe bundle type container with seven pipes

A container and tube-bundle technology, which is applied in the field of 7-tube 720-tube-bundle containers, can solve the problems of small water volume of container tube bundles and cannot meet market demand, and achieve the effect of reducing transportation costs and reducing use waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

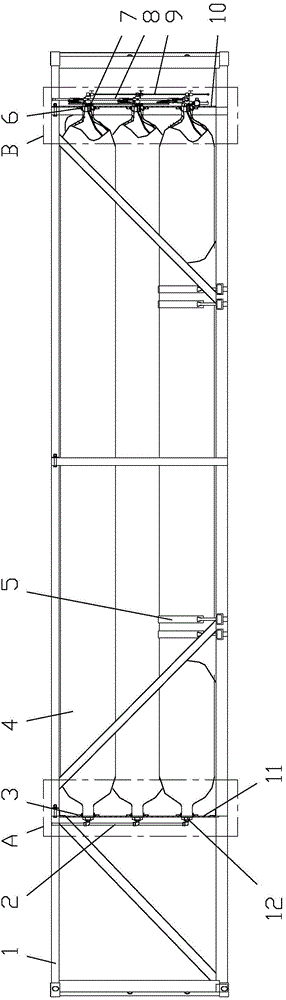

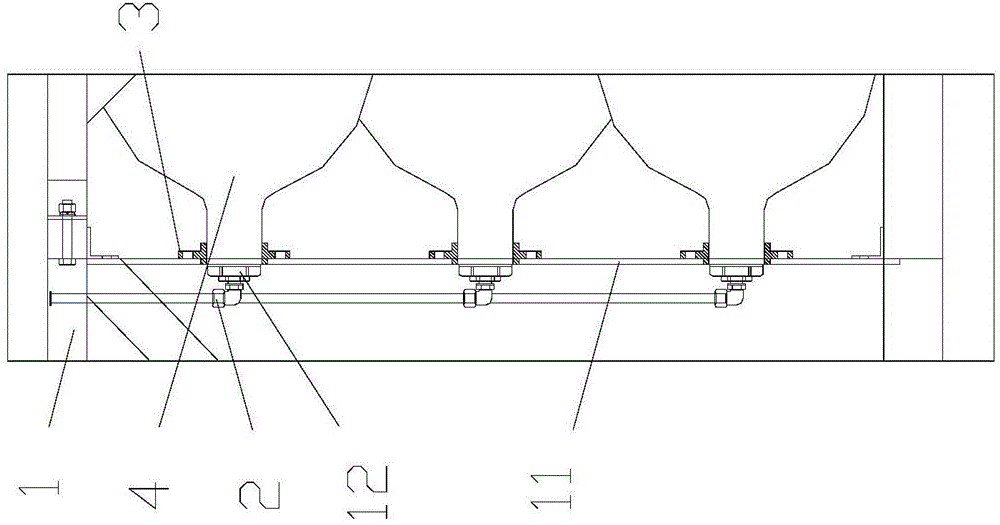

[0012] Such as figure 1 As shown, there is a 720-type gas cylinder group 4 in the container 1, and the two ends of the 720-type gas cylinder group 4 are respectively fixed with the front and rear support plates 11 and 10 through the front and rear flanges 3, 6, bolts and nuts, and the front support plate 11 is screwed to the container 1, and the rear support plate 10 is welded and fixed to the container 1; the front end of the 720-type gas cylinder set 4 is fixed to the front-end safety device 2 through the front-end plug 12, and the rear end of the 720-type gas cylinder set 4 is fixed through the rear end plug 7. Fix the rear end safety and operation device 8, the charging and unloading device 9 and the sewage discharge device 18.

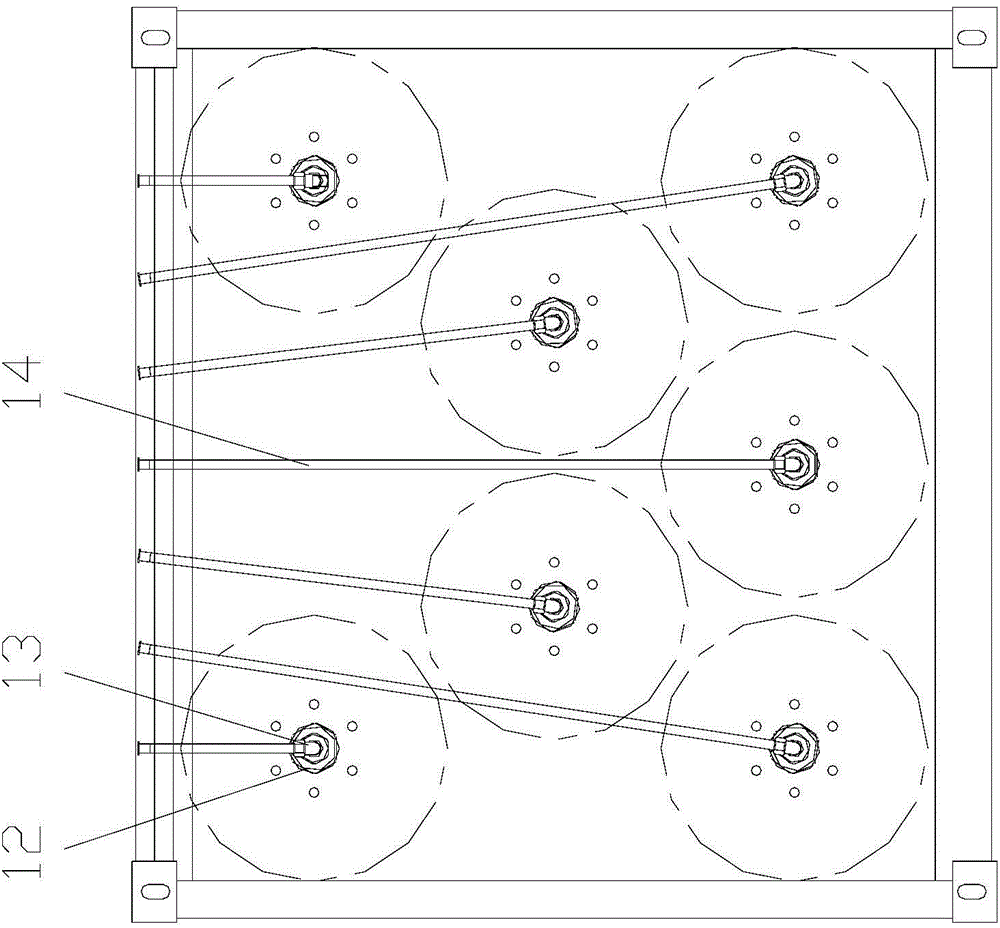

[0013] The 720-type gas cylinder group 4 has three layers, three bottom layers, two middle and upper layers respectively, and the gas cylinders in the lower layer are fixed with the container 1 by binding straps 5 .

[0014] Such as figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com