A forming device for a micro-carrier tape

A forming device and carrier tape technology, which is applied to belts, other household appliances, household appliances, etc., can solve the problems that cannot completely overcome the stretchability and shrinkage of sheet materials, and achieve good forming degree, improved forming degree and precision , The effect of simple and light device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

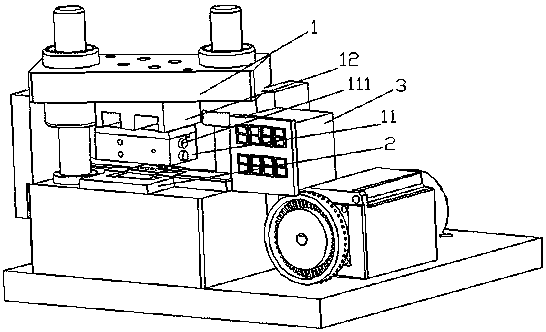

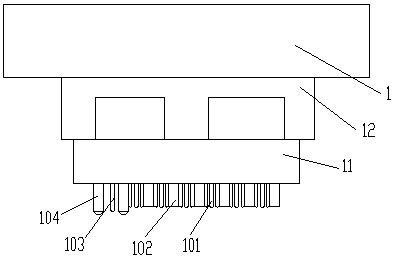

[0031] A kind of forming device of miniature carrier tape, as attached figure 1 , 2 As shown, it includes an upper mold base 1, a lower mold base 2 and a driving device arranged on the base, and a servo motor that drives the tape roll to rotate. The driving device adopts a motor to drive the upper mold base 1 to reciprocate up and down. Pocket forming needles 101 and positioning punching needles 102 arranged side by side are installed on the upper die base 1, each of which is provided with a plurality of them. According to processing requirements, the present embodiment adopts 24 pocket forming needles and 6 positioning punching needles. According to the shapes of pockets and positioning holes of carrier tapes commonly seen in the market, the pocket forming pins 101 are square, and the positioning punching pins 102 are circular. The lower mold base 2 is provided with a recess corresponding to the pocket forming needle 101 and a through hole corresponding to the positioning pu...

Embodiment 2

[0033] A molding device for a miniature carrier tape, comprising an upper mold base 1, a lower mold base 2 and a driving device. The driving device adopts a motor to drive the upper mold base 1 to reciprocate up and down. Pocket forming needles 101 and positioning punching needles 102 arranged side by side are installed on the upper die base 1, each of which is provided with a plurality of them. According to processing requirements, the present embodiment adopts 24 pocket forming needles and 6 positioning punching needles. According to the shapes of pockets and positioning holes of carrier tapes commonly seen in the market, the pocket forming pins 101 are square, and the positioning punching pins 102 are circular. The lower die base 2 is provided with a recess corresponding to the pocket forming needle 101 and a through hole corresponding to the positioning punch 102, and the lower die base is provided with a groove for accommodating the recess, and the recess can be vertically...

Embodiment 3

[0037] A molding device for a miniature carrier tape, comprising an upper mold base 1, a lower mold base 2 and a driving device. The driving device adopts a motor to drive the upper mold base 1 to reciprocate up and down. Pocket forming needles 101 and positioning punching needles 102 arranged side by side are installed on the upper die base 1, each of which is provided with a plurality of them. According to processing requirements, the present embodiment adopts 24 pocket forming needles and 6 positioning punching needles. According to the shape of the pocket and the positioning hole of the carrier tape commonly used in the market, the pocket forming pin 101 adopts a square shape, and the positioning punching pin 102 adopts a circular shape. The lower mold base 2 is provided with a recess corresponding to the pocket forming needle 101 and a through hole corresponding to the positioning punch 102 . On the upper mold base 1, there are first positioning pins 103 and second positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com