Bottle blank heater

A heater and preform technology, which is applied in the field of blow molding heating, can solve the problems of high heating temperature, uneven heating of the preform, and uneven temperature distribution inside the casing, and achieves the effect of high utilization efficiency and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

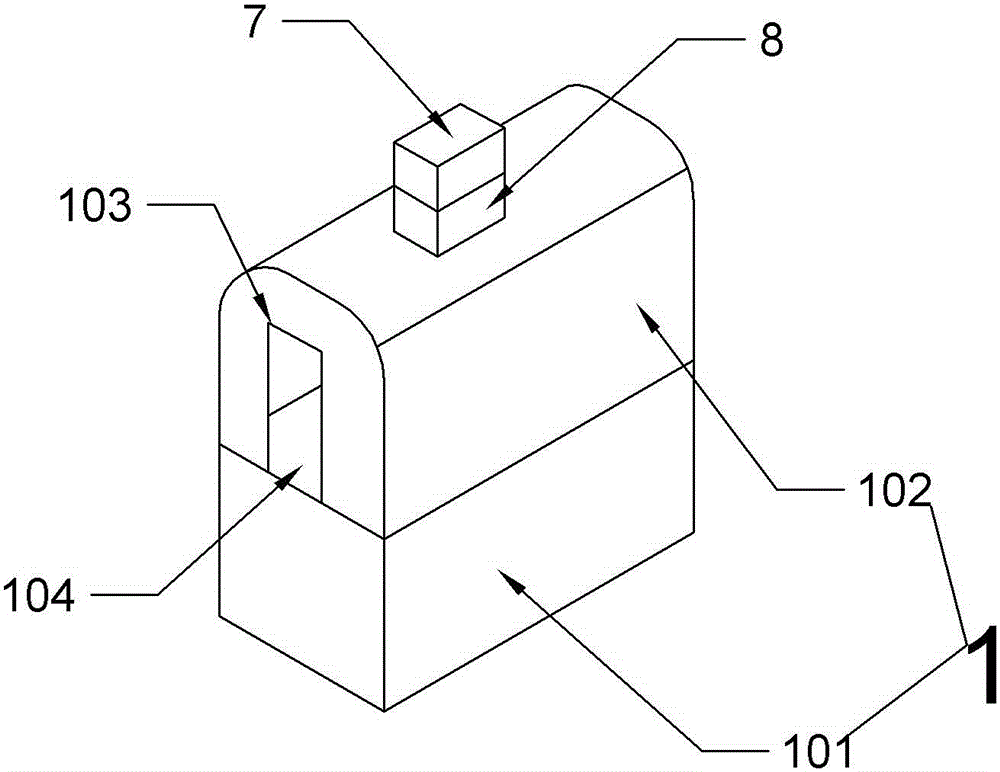

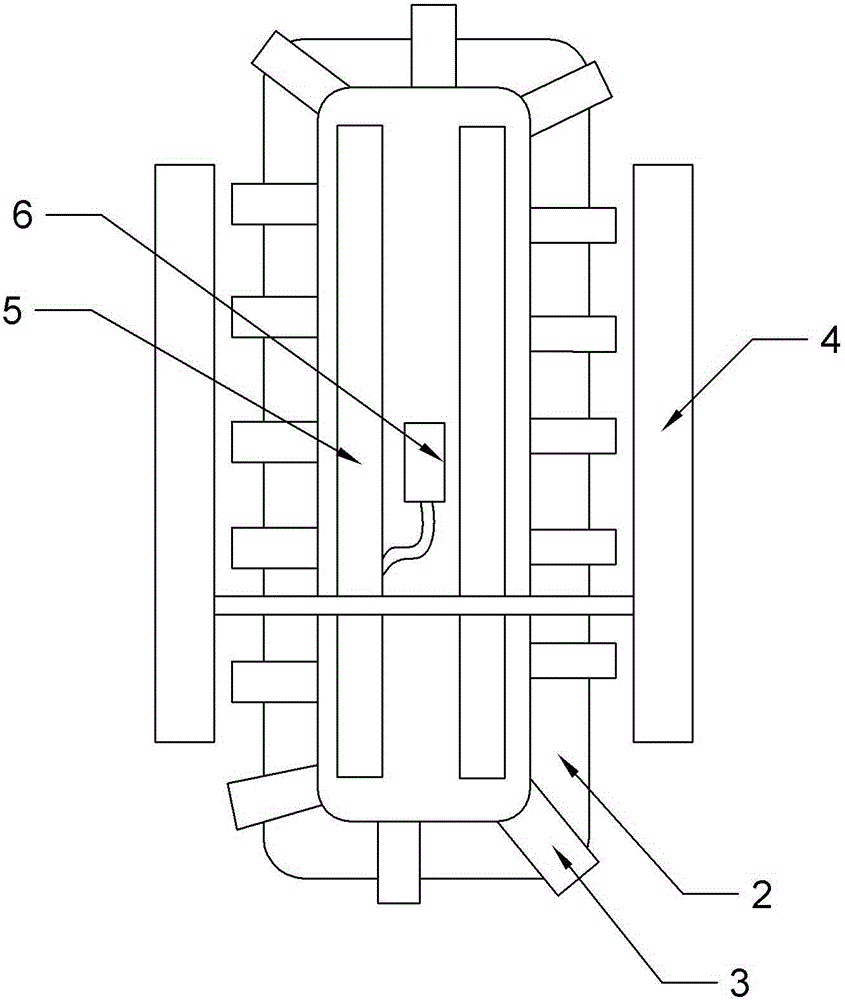

[0018] Such as figure 1 with figure 2 As shown, a preform heater includes a casing 1, and the casing 1 is divided into two parts, one part is the operating cabinet 101 below, and the other part is a U-shaped heating cover 102 located at the upper end of the operating cabinet 101. The heating cover 102 There are feeding doors 103 front and back. The lower end of the operation cabinet 101 is provided with universal wheels for convenient transportation. The upper end of the operating cabinet 101 is provided with an operating table 104, and the part of the operating table 104 located in the heating mantle 102 is provided with a transmission chain 2, which is driven by large gears arranged at both ends, and a pinion engaged with it is provided below the large gear. The transmission chain 2 is provided with a plurality of support seats 3, and is distributed equidistantly, which is convenient for fixing the preform and rotating with the transmission chain 2. The transmission chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com