Circular pipe transfer box type column and manufacturing method thereof

A manufacturing method and box-turning technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of structural design affecting supporting force, affecting the quality of steel structures, and having potential safety hazards, so as to eliminate welding residual stress, improve supporting capacity, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

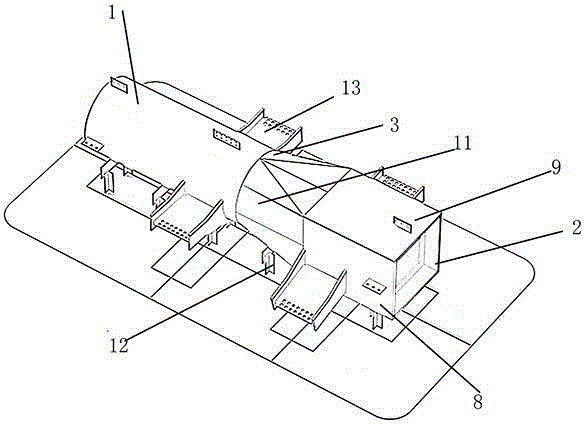

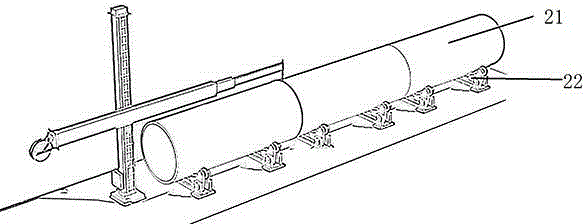

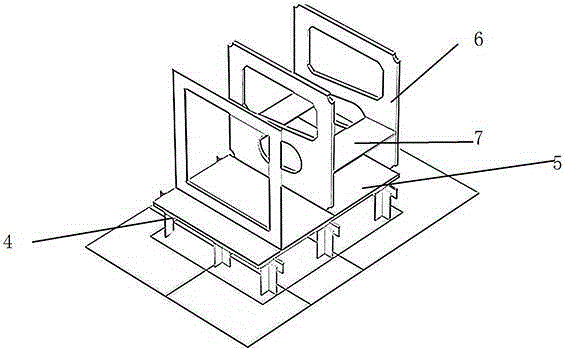

[0048] Such as figure 1 , figure 2 , image 3 and Figure 4A circular tube transfer box-type column shown includes: a cylinder body 1, a supporting frame 4, a box bottom plate 5, a transverse partition plate 6, a stiffening plate 7, a side sealing plate 8, a top sealing plate 9, and a second support tire frame 10, wall plate 11, integral tire frame 12 and corbel 13, the box bottom plate 5 is arranged on the supporting tire frame 4, the transverse partition 6 is arranged on the box body bottom plate 5, and the stiffening plate 7 is set Between the diaphragms 6, the side seals 8 are arranged on both sides of the box bottom plate 5, and the top seals 9 are arranged above the two side seals 8 to form the box 2, and the second The support tire frame 10 is fixed on the ground, the wall plate 11 is set on the second support tire frame 10 to form a circle 3, the integral tire frame 12 is set at a designated position for construction, the cylinder body 1, box The body 2 and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com