Hoop bending machine

A hoop bending machine and bending mechanism technology, applied in the field of hoop bending machines, can solve the problems of reduced service life of the reducer, large moment of inertia of the reducer, inconvenient maintenance and replacement, etc., and achieve stable performance, small moment of inertia, and easy maintenance The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

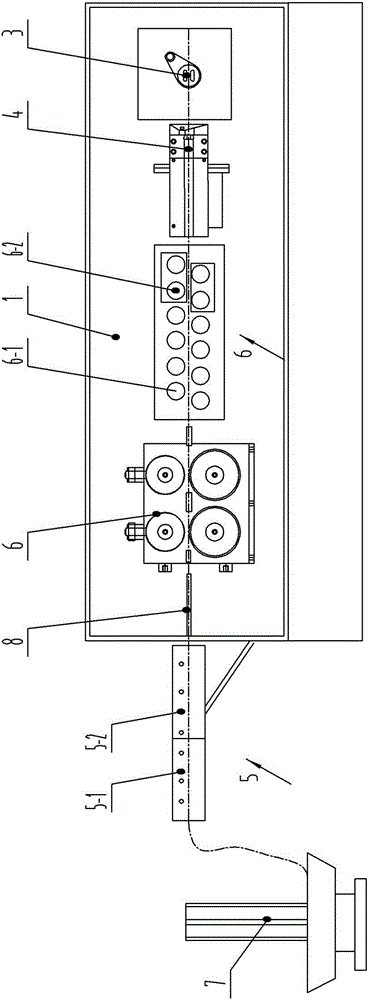

[0032] see figure 1 , in the figure, the hoop bending machine of the present invention includes a frame 1, and the frame is provided with a traction mechanism 2, a straightening mechanism, a bending mechanism 3 and a shearing mechanism 4, wherein the straightening mechanism has two groups, respectively front and rear straightening Mechanism 5 and up and down straightening mechanism 6, and front and rear straightening mechanism and up and down straightening mechanism are respectively placed on the two sides of traction mechanism, and pay-off frame 7 is arranged simultaneously before front and rear straightening mechanism. On the frame, a plurality of guide sleeves 8 are arranged along the moving direction; the front and rear straightening mechanisms and the upper and lower straightening mechanisms respectively include fixed wheel sets 5-1, 6-1 and adjusting wheel sets 5-2, 6-2.

[0033] see Figure 2-3 , among the figures, the traction mechanism includes a pinch wheel set and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com