Wear-resistant ball cleaning device

A technology of cleaning device and wear-resistant ball, applied in the field of wear-resistant ball processing, can solve the problems of inconsistent impurity removal effect, long time consumption of wear-resistant ball, deformation of wear-resistant ball, etc. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

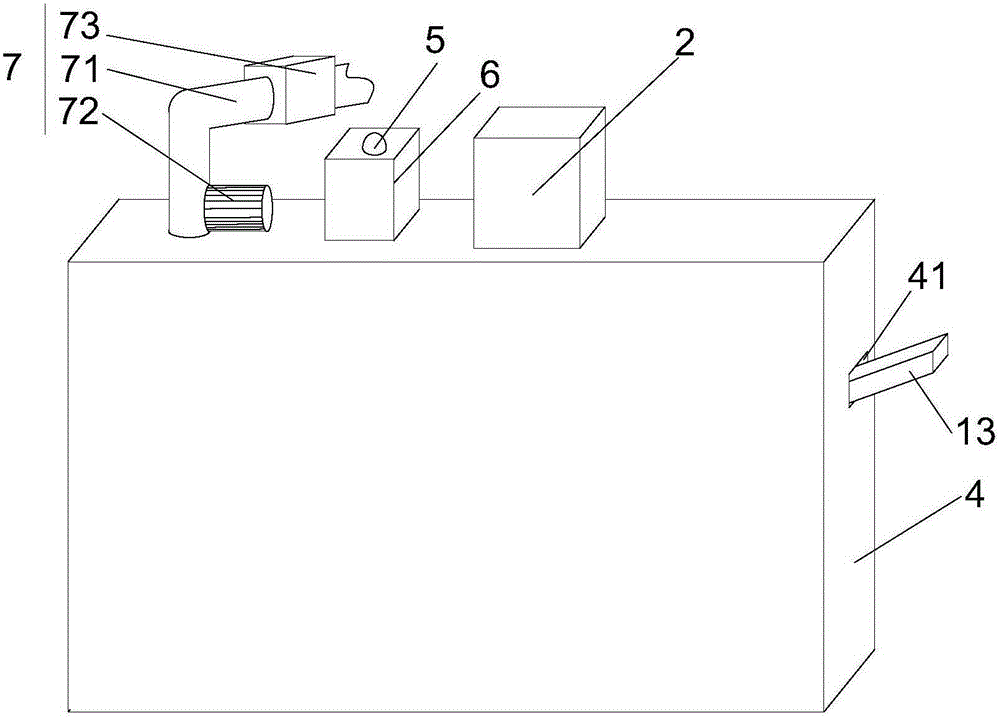

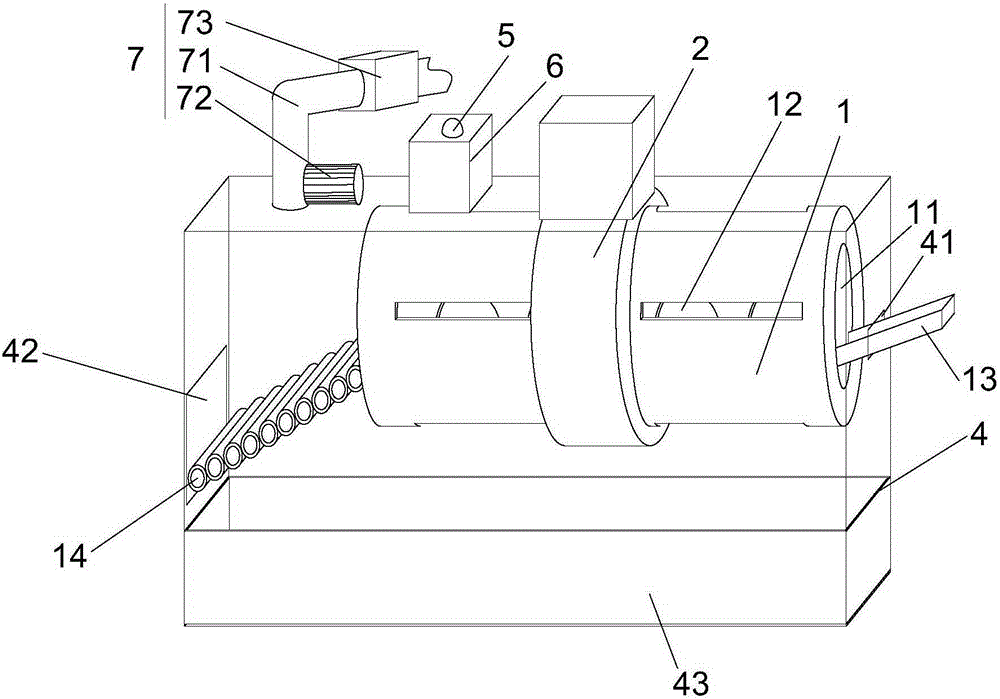

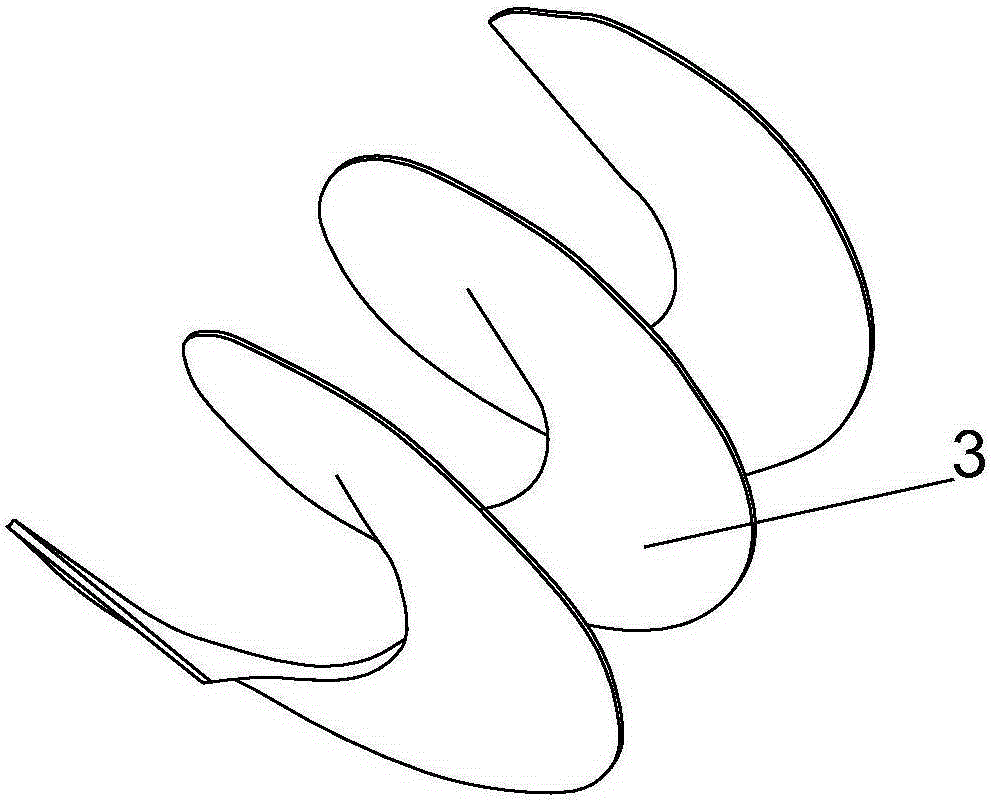

[0022] refer to figure 1 , figure 2 and image 3 As shown, a kind of wear-resisting ball cleaning device that the present invention proposes, comprises dust removal box 1 and driving device 2;

[0023] A spiral blade 3 is installed in the dust removal box 1, and the driving device 2 is connected with the dust removal box 1 and drives the dust removal box 1 to rotate around the axis. The inner wall of the dust removal box 1 and the spiral blade 3 are provided with a brush layer, and one end of the dust removal box 1 is provided with a second Once the entrance 11 is entered, the other end of the dust removal box 1 is provided with a first ball exit.

[0024] In this embodiment, the dust removal box 1 is provided with a plurality of through holes 12 .

[0025] In this embodiment, the wear-resistant ball cleaning device also includes an outer box 4 installed on the periphery of the dust removal box 1 , and the outer box 4 is provided with a second ball inlet 41 and a second ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com