Preparation method and application of full-interpenetrating membrane based on quaternized polyvinyl alcohols

A technology of polyvinyl alcohol and polyvinyl alcohol, which is applied in the preparation of fully interpenetrating membranes based on quaternized polyvinyl alcohols, the application field of competitive adsorption of rhodamine and Congo red, and can solve the problem of poor film stability and compatibility, etc. problem, achieve the effect of reducing swelling degree and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

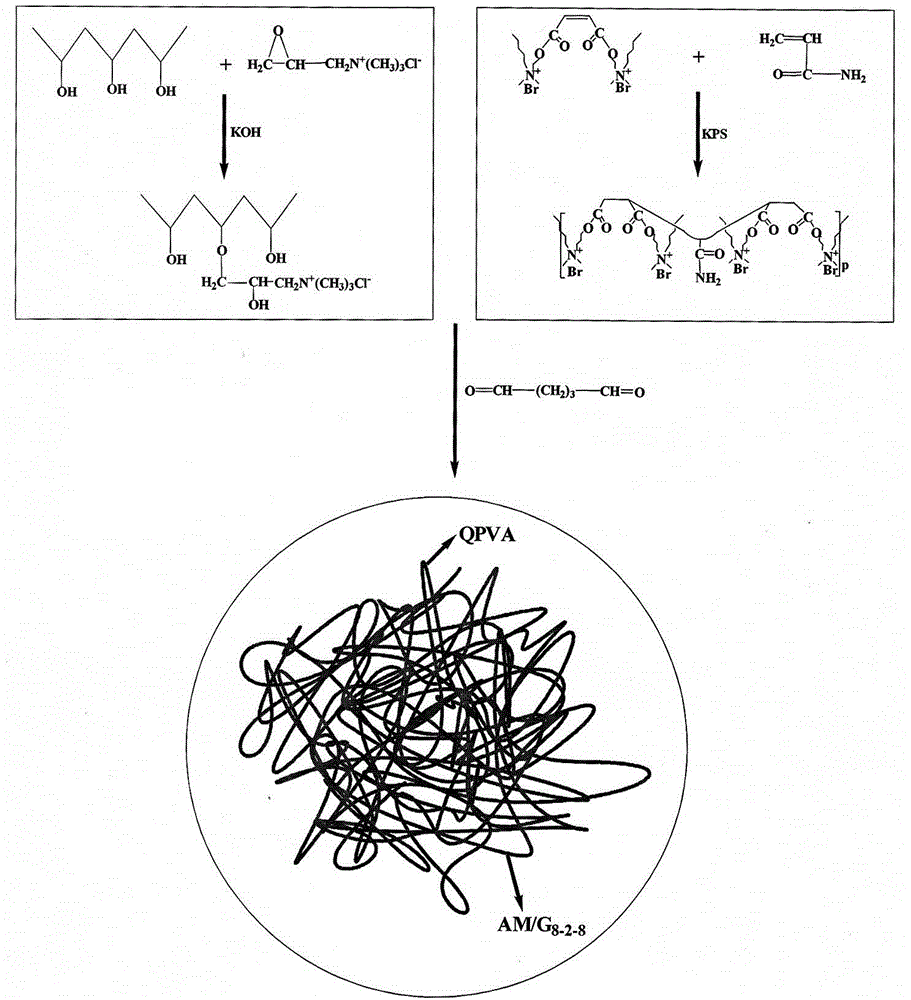

[0018] The steps of the method for preparing the quaternized polyvinyl alcohol fully interpenetrating membrane are as follows.

[0019] (1) Preparation of quaternized polyvinyl alcohol. At room temperature, slowly add 0.908 g of polyvinyl alcohol (PVA) into the flask and start stirring, and heat in a water bath. The temperature of the water bath is gradually raised to about 90°C to completely dissolve the PVA; the completely dissolved PVA is cooled to room temperature, and 4.708g of epoxypropyltrimethylammonium chloride (EPTMAC) is added to the flask, and stirred to make it The reactants are in full contact; every 10s, slowly add potassium hydroxide solution with a concentration of 10% into the round bottom flask, drop 4-5 drops each time, and the total amount of potassium hydroxide solution is 1-2mL; after the reaction, The product was cooled to room temperature, poured into a pre-prepared beaker containing 20 mL of isopropanol solution, and stirred continuously with a glass...

Embodiment 2

[0022] The steps of the method for preparing the quaternized polyvinyl alcohol fully interpenetrating membrane are as follows.

[0023] (1) Preparation of quaternized polyvinyl alcohol. At room temperature, slowly add 0.908 g of polyvinyl alcohol (PVA) into the flask and start stirring, and heat in a water bath. The temperature of the water bath is gradually raised to about 90°C to completely dissolve the PVA; the completely dissolved PVA is cooled to room temperature, and 4.708g of epoxypropyltrimethylammonium chloride (EPTMAC) is added to the flask, and stirred to make it The reactants are in full contact; every 10s, slowly add potassium hydroxide solution with a concentration of 10% into the round bottom flask, drop 4-5 drops each time, and the total amount of potassium hydroxide solution is 1-2mL; after the reaction, The product was cooled to room temperature, poured into a pre-prepared beaker containing 20 mL of isopropanol solution, and stirred continuously with a glass...

Embodiment 3

[0026] The steps of the method for preparing the quaternized polyvinyl alcohol fully interpenetrating membrane are as follows.

[0027] (1) Preparation of quaternized polyvinyl alcohol. At room temperature, slowly add 0.908 g of polyvinyl alcohol (PVA) into the flask and start stirring, and heat in a water bath. The temperature of the water bath is gradually raised to about 90°C to completely dissolve the PVA; the completely dissolved PVA is cooled to room temperature, and 4.708g of epoxypropyltrimethylammonium chloride (EPTMAC) is added to the flask, and stirred to make it The reactants are in full contact; every 10s, slowly add potassium hydroxide solution with a concentration of 10% into the round bottom flask, drop 4-5 drops each time, and the total amount of potassium hydroxide solution is 1-2mL; after the reaction, The product was cooled to room temperature, poured into a pre-prepared beaker containing 20 mL of isopropanol solution, and stirred continuously with a glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com