Submerged membrane separation device and its operating method

A submerged and separation membrane technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of insufficient friction between membrane filaments, etc., and achieve reduced operating power consumption, high energy consumption, and reduced lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

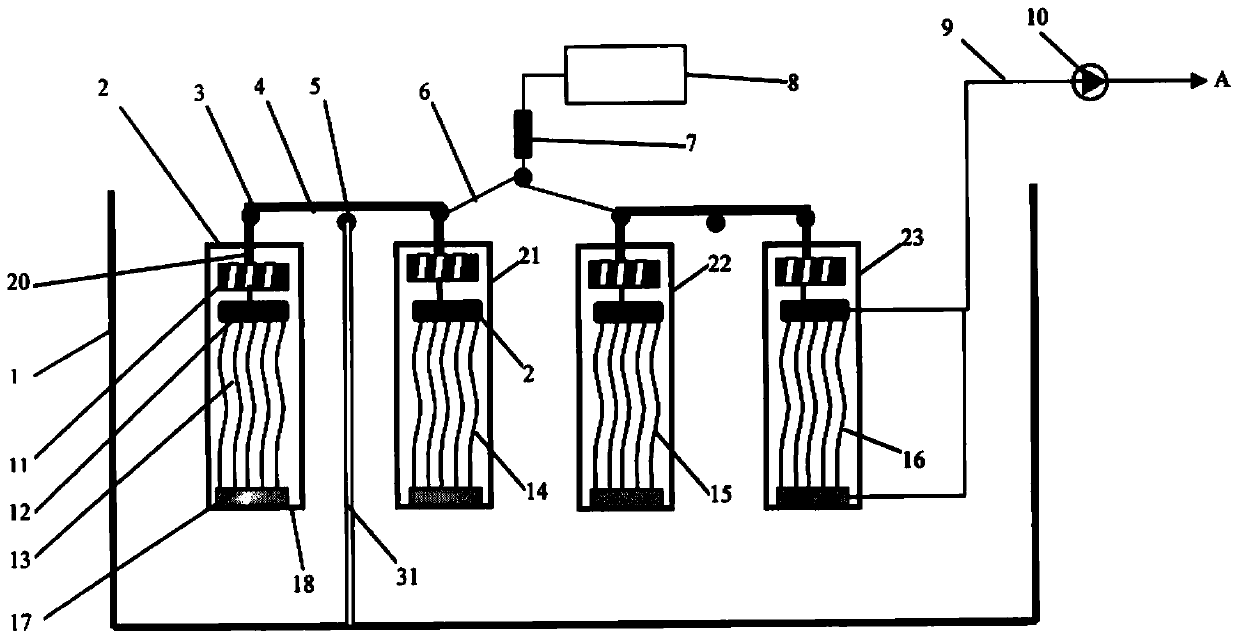

[0026] Embodiment one, such as figure 1 Shown: there are multiple membrane unit frames, shown as the first membrane frame 2, the second membrane frame 21, the third membrane frame 22, and the fourth membrane frame 23, which are respectively immersed in the water tank 1; The two cantilever ends are respectively connected to the upper ends 12, 24 of the membrane unit 13 and the membrane unit 14 through the rotatable connector 3 to form a balance group; 5 is the gravity balance fulcrum of the balance bar, fixed on the bracket 31; Another balance bar connects the membrane unit 15 and the membrane unit 16 to form another balance group; the two balance groups form a linkage group through the linkage rope 6 and the traction component 7 and the traction motor 8 . The improvements are: cancel the high energy consumption blower configuration of the prior art, and instead set the traction motor, the bracket 31 is vertically fixed in the water tank, can also be installed horizontally on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com