Hybrid electric vehicle power driving system based on double planetary lines

A hybrid vehicle and dual planetary technology, which is applied in the arrangement of multiple different prime movers of power units, general power units, and pneumatic power units, etc., can solve the problem of poor fuel economy, insufficient power performance, and system Efficiency decline and other problems, to achieve the effect of improving fuel economy, reducing system cost and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

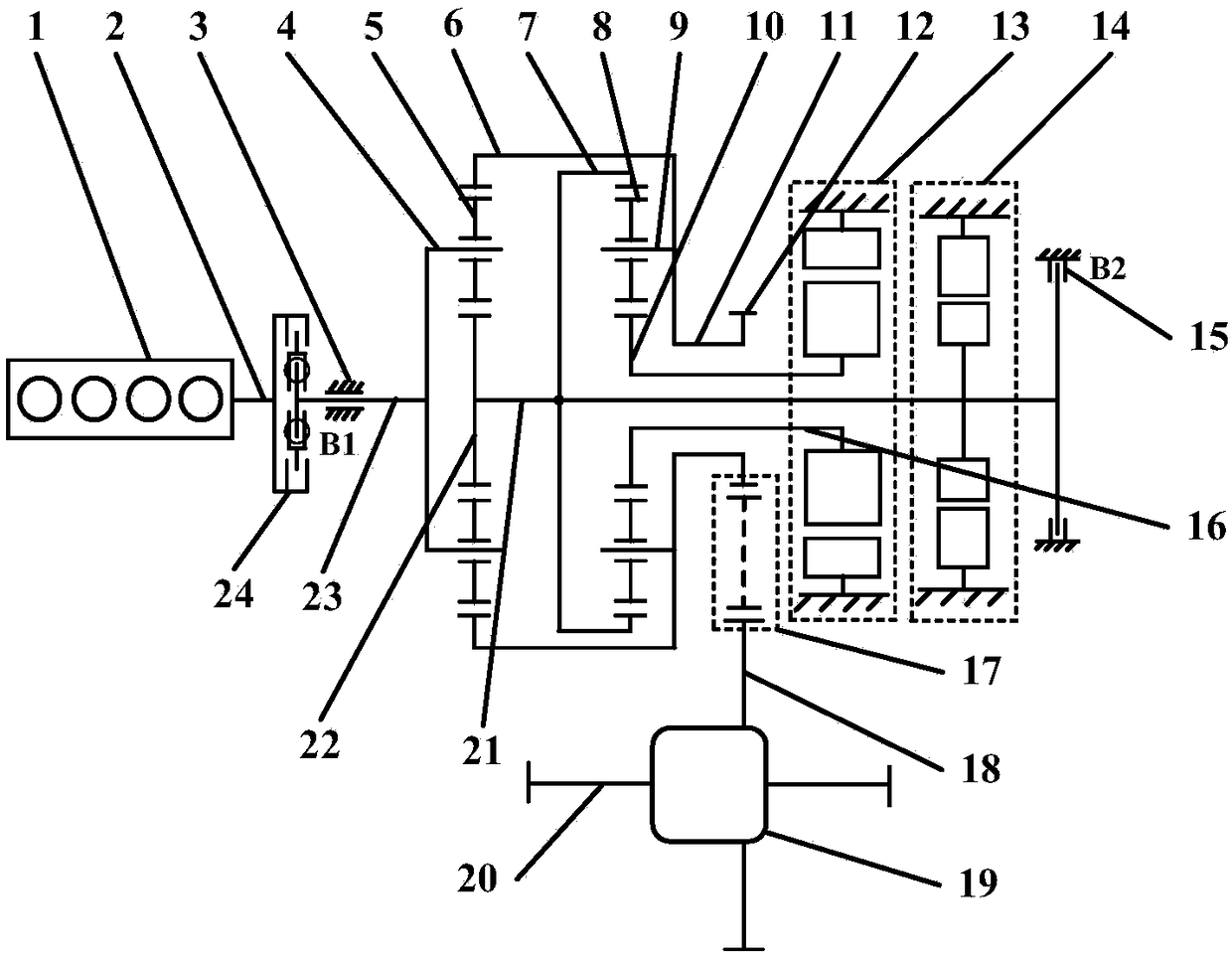

[0042] Such as figure 1 As shown, the hybrid electric vehicle power drive system based on the double planetary row provided by the present invention is characterized in that the system includes: a power output device, a brake, a power source, a first planetary row drive device, a second planetary row drive device and controller. The power source wherein comprises a first power source 1, a second power source 13 and a third power source 14, the first power source is preferably an engine, the second power source and the third power source adopt motors, and the second power source is hereinafter referred to as The motor 1 , the third power source is the motor 2 , and the brakes include a first brake 3 and a second brake 15 .

[0043] The first planetary row driving device adopted in the present invention includes a first sun gear 22, a first ring gear 6, a first planet carrier 4, and a first planetary gear 5 meshed with the first sun gear 22 and the first ring gear 6; The first...

Embodiment 2

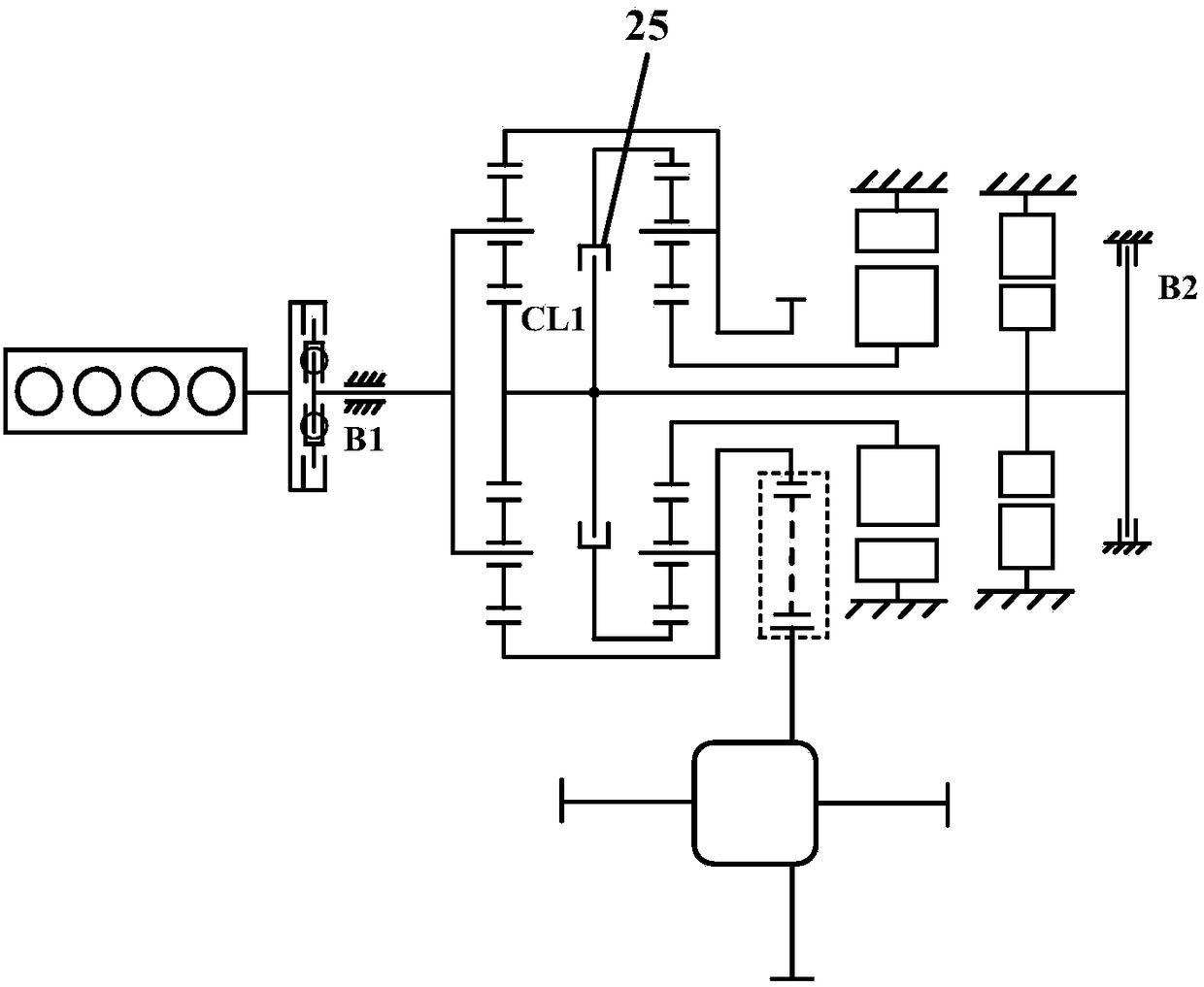

[0057] Such as figure 2 As shown, on the basis of Embodiment 1, the first clutch 25 is added, that is, the second ring gear 7 forms a clutch connection with the fourth drive shaft 21 through the first clutch 25, and the controller controls the first brake 3, the second brake 15 and The first clutch 25 is controlled individually or in combination. The control system is in pure electric mode, input power split mode, compound power split mode and parallel hybrid drive mode. The specific typical working modes are shown in Table 2.

[0058] Table 2 Correspondence figure 2 typical working mode

[0059]

[0060] Note: 0 means that the clutch or brake is disengaged or unlocked, and 1 means that the clutch or brake is engaged or braked. B1, B2, and CL1 denote a first brake, a second brake, and a first clutch, respectively.

Embodiment 3

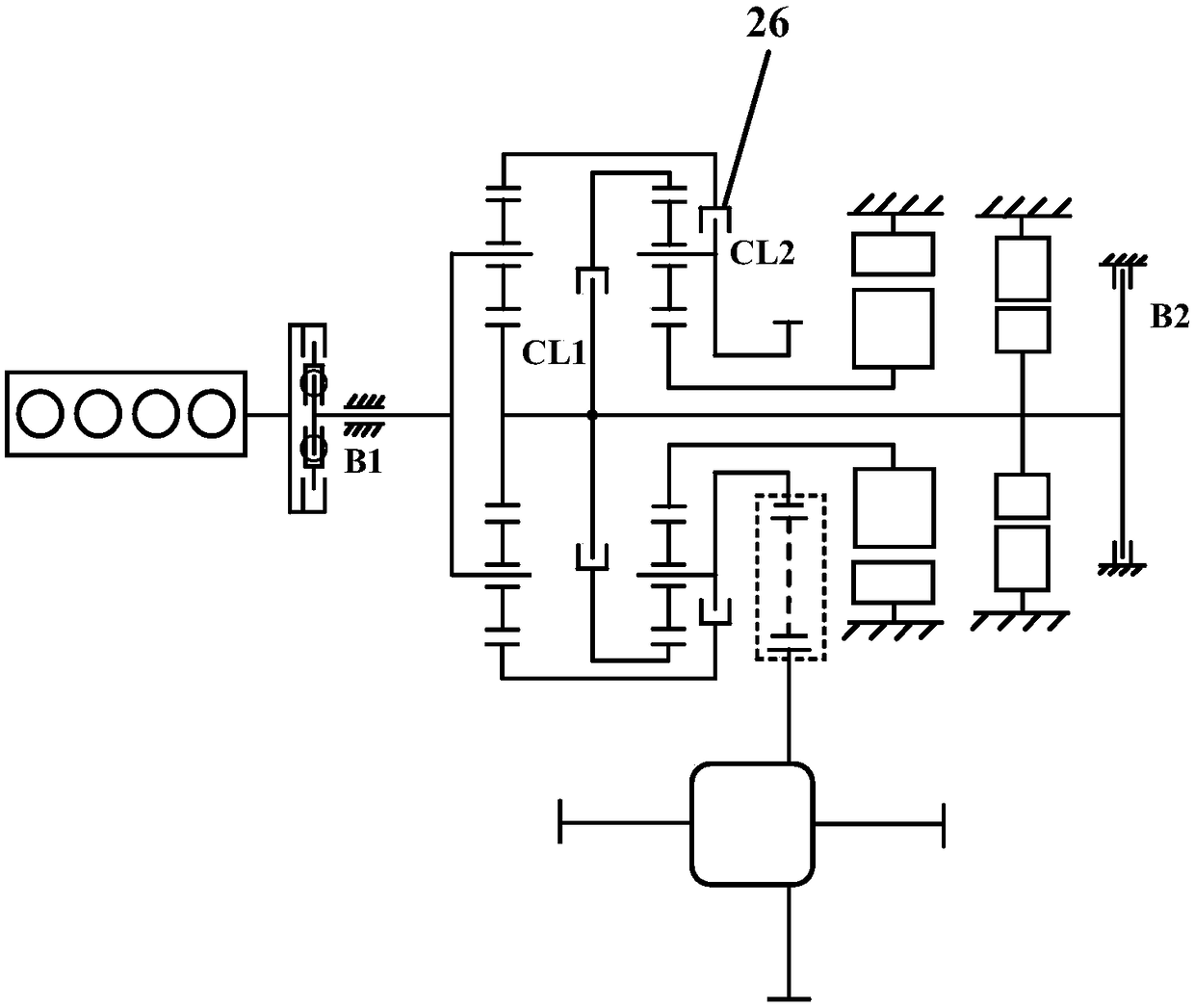

[0062] Such as image 3 As shown, the second clutch 26 is added on the basis of Embodiment 2, that is, the first ring gear 6 forms a clutch connection with the second planet carrier 9 through the second clutch 26, and the controller controls the first brake 3, the second brake 15, The first clutch 25 and the second clutch 26 are controlled independently or in combination. The control system is in pure electric mode, input power split mode, compound power split mode and parallel hybrid drive mode. The specific typical working modes are shown in Table 3.

[0063] Table 3 Correspondence image 3 typical working mode

[0064]

[0065] Note: 0 means that the clutch or brake is disengaged or unlocked, and 1 means that the clutch or brake is engaged or braked. B1, B2, CL1, and CL2 denote a first brake, a second brake, a first clutch, and a second clutch, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com