Reciprocating motion type inclined plate box dense classifier

A reciprocating motion and classifier technology, applied in the direction of the settling tank, etc., can solve the problems of unsatisfactory cleaning effect of the inclined plate or inclined plate box, easy deformation and falling off of the inclined plate, easy blockage of the settling channel, etc., to achieve automatic cleaning The effect is enhanced and reduced Effect of material consumption and strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

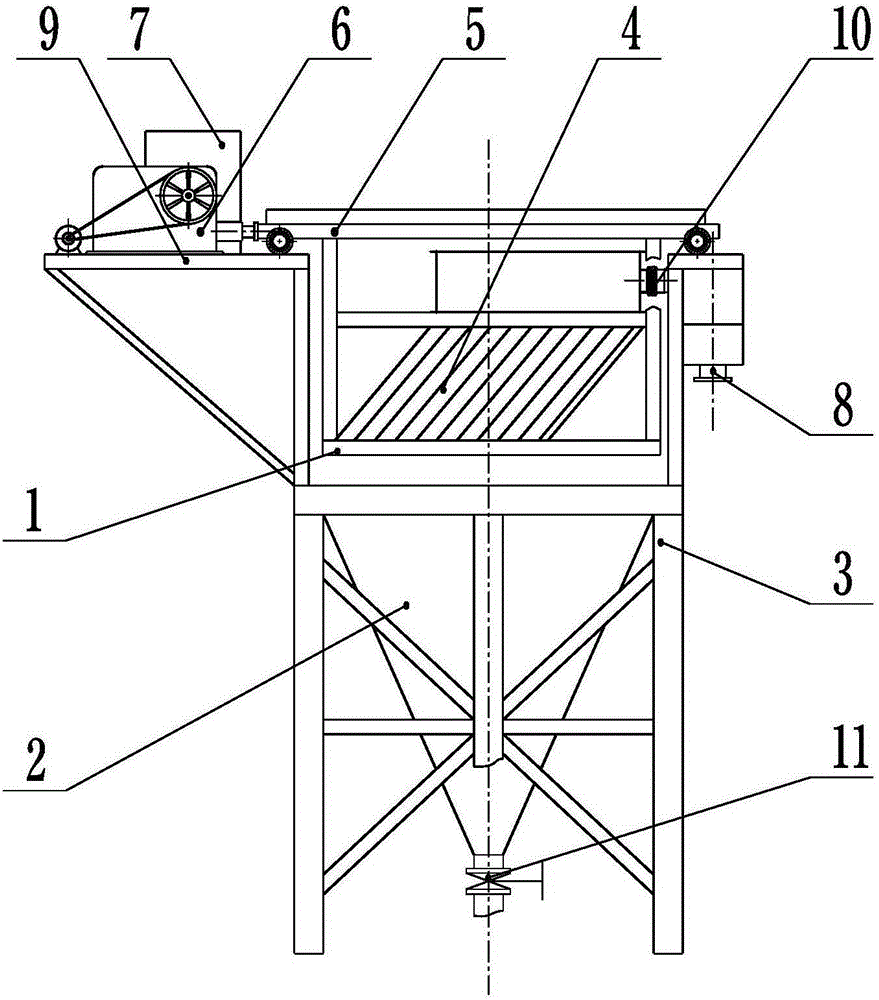

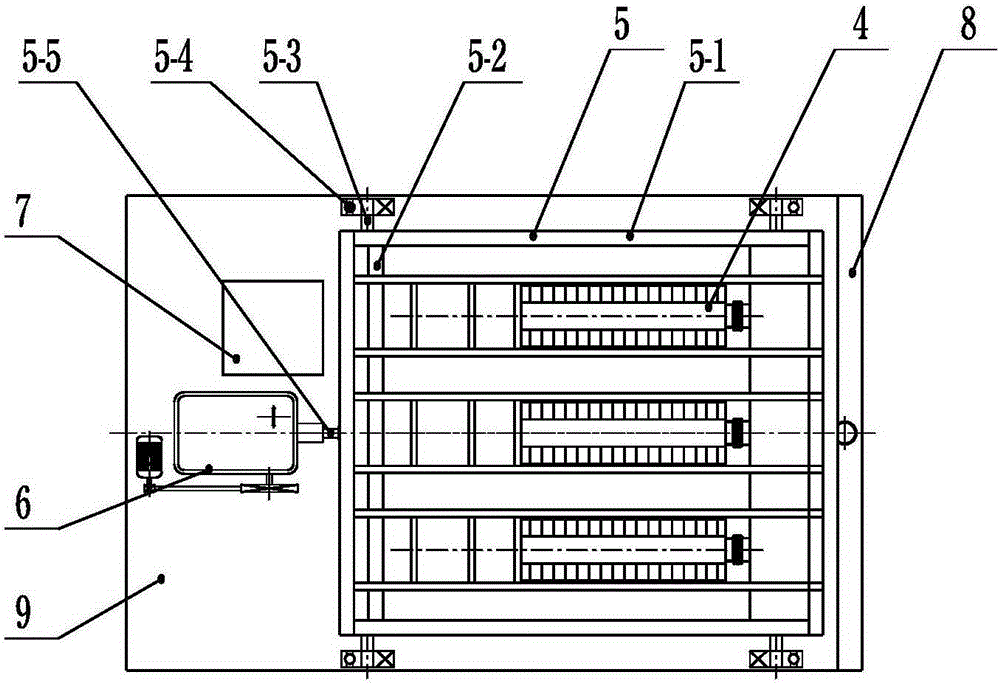

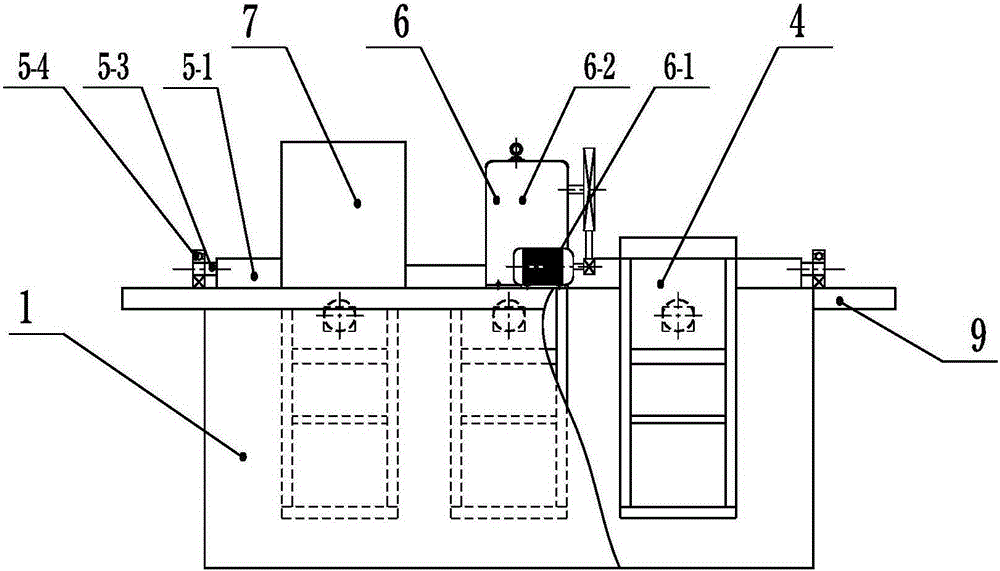

Embodiment 1

[0029] Example 1: In a lead-zinc beneficiation plant, it is necessary to carry out pre-plant dense backwater for flotation tailings. The slurry concentration of the tailings is 18%, and the flow rate is 90m 3 / h, the fineness is 80%-200 mesh, the underflow concentration after concentration is required to be ≥45%, the overflow solid content is ≤300mg / l, and the water return rate is ≥70%. The selected settlement area is 300m 2 1 reciprocating motion inclined plate box thickening classifier. The overall structure of the equipment and the inclined plate box module are made in the way of vibrating inclined plate box sedimentation separator (201310076262.1). The equipment is a box structure, and the upper box, the lower cone bucket and the support frame are all welded parts of steel structure. Install platforms on the left and right ends of the top of the upper box, install the slant box module installation bracket and drive system on the installation platform, install six slant ...

Embodiment 2

[0031] Example 2: In a certain ilmenite beneficiation plant, the pulp before flotation needs to be concentrated and deslimed, and the upper limit of the deslimed particle size is 20 μm. The ore feeding concentration of the pulp is 12%, and the flow rate is 1100m 3 / h, the content of -200 mesh is 75%, the underflow concentration after concentration is required to be 30-40%, and the content of -20μm in the overflow is ≥93%. The selected settlement area is 800m 2 1 reciprocating motion inclined plate box thickening classifier. The overall structure of the equipment and the inclined plate box module are made in the way of vibrating inclined plate box sedimentation separator (201310076262.1). The equipment is a box-type structure, the upper box body is a welded steel structure, and the lower cone bucket and support frame are reinforced concrete structures, a total of four cone buckets. Install a slant box installation bracket of the invention patent on the platform of the left a...

Embodiment 3

[0033] Example 3: An alumina plant adopts the Bayer method to produce alumina, and a large amount of alumina red mud is produced during the production process. The red mud is separated by sedimentation and separation in the multi-stage countercurrent washing industry with a reciprocating inclined plate box dense classifier . The feeding concentration is 10-12%, the flow rate is 280m 3 / h, the underflow concentration after the required concentration is ≥30%, and the overflow solid content is ≤300mg / l. The designed settlement area is 720m 2 1 reciprocating motion inclined plate box thickening classifier. The overall structure of the equipment and the inclined plate box module are made in the way of vibrating inclined plate box sedimentation separator (201310076262.1). The equipment is a box-type structure, the upper box, the lower cone bucket and the support frame are welded parts of steel structure, a total of 2 cone buckets. Install the slant box module mounting bracket of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com