Composition, applications thereof and moisture retention preparation

A technology of composition and enzymatic hydrolysis product, which is applied in the direction of drug combination, cosmetic preparations, skin care preparations, etc., and can solve the problems of unsatisfactory moisturizing effect and single product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

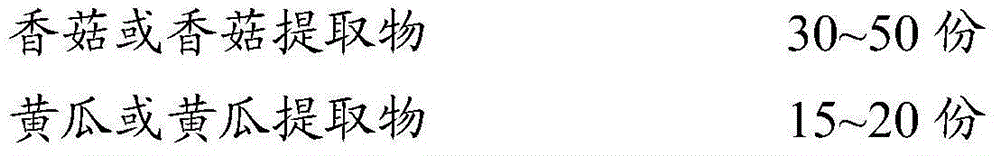

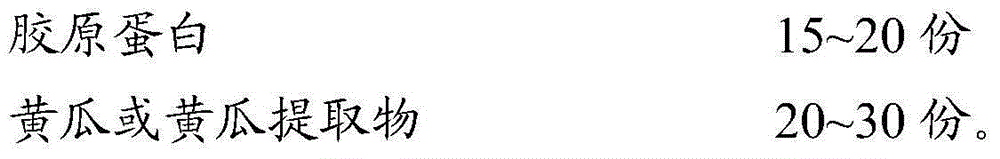

Method used

Image

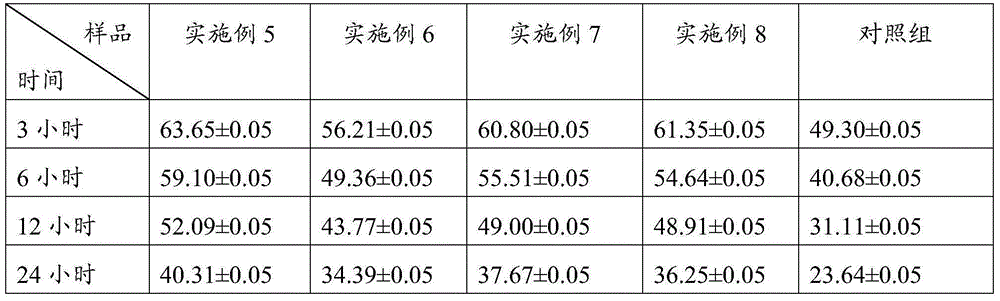

Examples

Embodiment 1

[0093] The preparation of embodiment 1 shiitake mushroom extract

[0094] ①. Crush the fruiting bodies of dried shiitake mushrooms, add 10 times the weight of water, stir evenly, heat to 95°C, maintain for 90min, and cool down to room temperature;

[0095] ②, step ① Ultrasonic treatment of the aqueous solution, adjust the pH value to 8.5, add protease with a specific activity of 50,000 international units per kg of dried shiitake mushrooms, and hydrolyze at 50°C for 180 minutes;

[0096] ③. Adjustment step ②The pH value of the hydrolyzate is 5.0, add protease (alkaline protease, trypsin or papain) with a specific activity of 50,000 international units per kg of dried shiitake mushrooms, hydrolyze at 50°C for 360min; inactivate the enzyme, and cool it down to room temperature ;

[0097] ④. Adjust the pH value of the inactivated hydrolyzate to 7.0 in step ③, heat to 95°C, keep for 180min, cool down to room temperature, centrifugally filter, and collect the filtrate;

[0098] 5...

Embodiment 2

[0099] The preparation of embodiment 2 cucumber extract

[0100] ①. Take fresh cucumbers, squeeze the juice with a juicer, collect the cucumber juice, add 5 times the amount of deionized water to the cucumber dregs, stir evenly, heat to 80°C, keep for 1 hour, cool down to room temperature, and add 30,000 deionized water per kg of cucumber dregs. The plant compound hydrolase with international unit specific activity is used for enzymolysis, the enzymolysis temperature is 50°C, and the enzymolysis time is 1 hour. After the enzymolysis is completed, the enzyme is inactivated, filtered, and the filtrate is taken for use.

[0101] ②. Combine cucumber juice and filtrate, add 5 / 10,000 carrageenan by liquid weight, stir thoroughly, place at 4°C for 2 hours, centrifuge, and take clear liquid, which is cucumber extract.

Embodiment 3

[0102] The preparation of embodiment 3 collagen polypeptides

[0103] ①. Take the fish skin and scales as the leftovers of aquatic product processing, wash them with tap water, add purified water 8 times the weight of the fish skin and scales, and ultrafinely pulverize them. After pulverization, the fish skin and scales can pass through a 200-mesh sieve, and set aside;

[0104] ②. Adjust the pH value to 8.5 with 10.0 mol / L lye, maintain the pH value at 8.5, add alkaline protease (add 0.1% alkaline protease by weight of fish skin and scale) for enzymolysis for 120 minutes, and the enzymatic hydrolysis temperature is 55°C. After enzymatic hydrolysis, heat up to 90°C-100°C for 10 minutes to inactivate the enzyme, then cool down to 60°C for later use;

[0105] ③. Add 0.5% activated carbon for decolorization, maintain the temperature at 60°C for 60 minutes, stir for decolorization, filter, adjust the pH value to 6.0 with 10.0mol / L citric acid solution, and obtain collagen polypepti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com