Method for preparing reconstituted tobacco flakes based on low-grade tobacco raw materials

A technology for reconstituted tobacco and thin slices, which is applied in the fields of tobacco, tobacco preparation, and applications. It can solve the problems of insufficient curling in the production of thin slices, large investment in equipment and space, and poor filling performance, so as to reduce tar release, reduce site investment, The effect of high filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The discarded tobacco stems and stem heads produced by the threshing and re-baking factory are pressed into a density of 0.6g / cm with a diameter of 15cm by using a general-purpose tobacco stem and tobacco rod press machine 3 Tobacco material rod round rod; the prepared above-mentioned tobacco material rod is crushed and processed with a general-purpose shavings grinder, and the shavings are sieved to obtain tobacco shavings with a thickness of 0.1-0.4mm, a length of 10-30mm, and a width of 0.5-2mm After the moisture content of the silk is balanced to 12±0.5%, it can be directly used as reconstituted tobacco flakes for cigarette production; the shavings of unsuitable size after sieving are added as raw materials to waste tobacco stems for re-making rods and shavings. The prepared reconstituted tobacco sheet is marked as A.

Embodiment 2

[0027] Fully mix the tobacco powder and bagasse powder produced in the production process of the cigarette factory according to the mass ratio of 5:1, and press it to a density of 1.0g / cm with a diameter of 20cm by using a general-purpose tobacco stem press machine 3 Tobacco material rod round rod; the prepared above-mentioned tobacco material rod is crushed and shavings processed by a general-purpose shavings grinder, and the shavings are sieved to obtain tobacco shavings with a thickness of 0.1-0.3mm, a length of 10-30mm, and a width of 0.5-2mm After the silk balance moisture reaches 12±0.5%, it can be directly used as reconstituted tobacco flakes for cigarette production; the tobacco shavings with unsuitable size after sieving are added as raw materials to the aforementioned mixture to re-make rods and then shavings. The produced reconstituted tobacco sheet is recorded as B.

Embodiment 3

[0029] Spray the tobacco extract on the discarded tobacco stems and stem heads produced by the threshing and redrying factory according to the mass ratio of 0.5:100, and press it into a cross-sectional length and width of 10cm*15cm with a density of 1.3g / cm 3 Tobacco material rod block; the prepared above-mentioned tobacco material rod is crushed and processed with a general-purpose shavings grinder, and the shavings are sieved to obtain tobacco shavings with a thickness of 0.2-0.4mm, a length of 10-30mm, and a width of 0.5-2mm After the moisture content of the silk is balanced to 12±0.5%, it can be directly used as reconstituted tobacco flakes for cigarette production; the shavings of unsuitable size after sieving are added as raw materials to waste tobacco stems for re-making rods and shavings. The prepared reconstituted tobacco sheet is denoted as C.

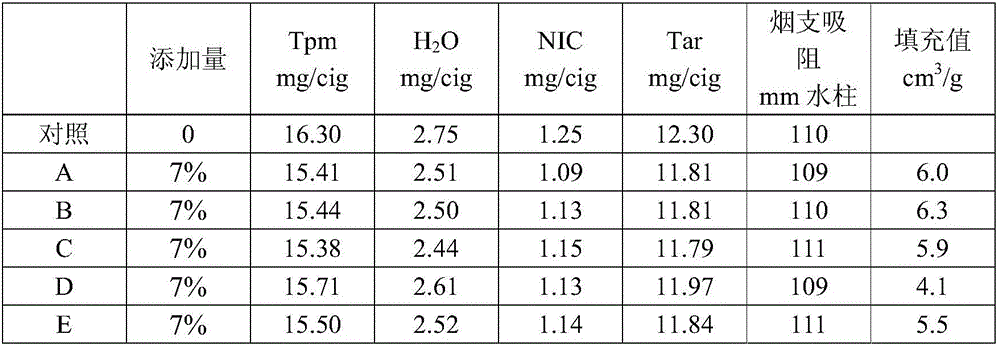

[0030] The sheet samples A, B, and C prepared above, the conventional thick pulp method sheet D and the paper-making metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com