Production method of rice product rich in gamma-aminobutyric acid

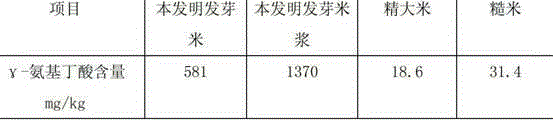

A technology of GABA rice and its production method, which is applied in the field of rice products rich in r-aminobutyric acid (GABA), can solve the problems of poor taste, poor digestion and absorption rate, nutrient loss, and unacceptability by people. Achieve the effects of reduced fat content, increased soluble sugar content, and soft color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A production method rich in gamma-aminobutyric acid rice products, the steps are as follows:

[0021] (1) Cleaning and disinfection of raw materials: separate the newly harvested rice hulls and paddy to obtain raw brown rice, remove broken grains, mildewed grains and heterochromatic grains, sterilize the raw raw brown rice with 0.05% sodium hypochlorite solution, and rinse with tap water Wash away the residual sodium hypochlorite;

[0022] (2) Soak the raw brown rice according to the volume ratio of raw brown rice and calcium chloride solution with a concentration of 0.2% as 4:1. The soaking temperature is 30° C. and the soaking time is 6 hours. The raw material brown rice is spread flat on a mesh tray or mesh belt that can drain water, and sent to the cultivation room for cultivation to make it germinate. The temperature of the cultivation chamber is 30°C, and the cultivation time is 48h. The water mist method is used (for example, a common household humidifier is used...

Embodiment 2

[0026] (1) Cleaning and disinfection of raw materials: separate the newly harvested rice hulls and paddy to obtain raw brown rice, remove broken grains, mildewed grains and heterochromatic grains, sterilize the raw raw brown rice with 0.05% sodium hypochlorite solution, and rinse with tap water Wash away the residual sodium hypochlorite;

[0027] (2) Soak the raw brown rice according to the volume ratio of raw brown rice and 0.25% calcium chloride solution at a volume ratio of 4:1. The soaking temperature is 25° C. and the soaking time is 3 hours. The raw material brown rice is spread flat on a mesh tray or mesh belt that can drain water, and sent to the cultivation room for cultivation to germinate. The temperature of the cultivation chamber is 25°C, and the cultivation time is 36h. The water mist method is used (for example, a commonly used household humidifier is used for treatment) , the indoor relative humidity is maintained at 90-99%, and the compost is washed 2 times wi...

Embodiment 3

[0031] (1) Cleaning and disinfection of raw materials: separate the newly harvested rice hulls and paddy to obtain raw brown rice, remove broken grains, mildewed grains and heterochromatic grains, sterilize the raw raw brown rice with 0.05% sodium hypochlorite solution, and rinse with tap water Wash away the residual sodium hypochlorite;

[0032](2) Soak the raw brown rice according to the volume ratio of raw brown rice and 0.1% calcium chloride solution at a volume ratio of 4:1, the soaking temperature is 35°C, and the soaking time is 4 hours, and then washed with tap water, and the soaked and cleaned The brown rice as the raw material is spread flat on a mesh tray or mesh belt that can drain water, and sent to the cultivation room for cultivation to germinate. The temperature of the cultivation chamber is 35°C, and the cultivation time is 45h. The water mist method is used (for example, a common household humidifier is used for treatment) , the indoor relative humidity is ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com