Preparation method for lithium titanate negative electrode slurry of lithium battery

A technology of negative electrode slurry and lithium titanate, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uneven dispersion of conductive agents, affecting battery consistency, poor slurry stability, etc., and achieves short preparation time and equipment The effect of low wear and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

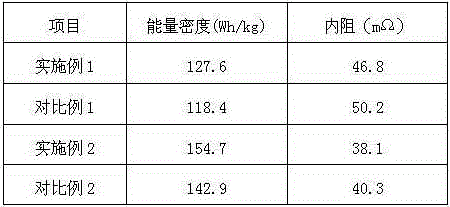

Embodiment 1

[0029] Lithium titanate prepared by anatase titanium dioxide is used as the negative electrode, SP is the conductive agent, according to Li 4 Ti 5 o 12 : SP: CMC: SBR = 94.0: 1.5: 2.0: 2.5 mass ratio, solvent deionized water is 100% of the total amount of the above components. The preparation steps are as follows:

[0030] 1. Add the thickener CMC into the deionized water solvent, dissolve it evenly with a mixer, take it out for use, and the time is 60 minutes;

[0031] 2. Add the negative electrode active material and conductive agent into the mixing tank to stir and disperse for 30 minutes, and scrape the powder on the stirring blade and the barrel at the time of 15 minutes and 30 minutes;

[0032] 3. Add 55% of the total amount of the thickener solution to the above stirred powder, stir and disperse for 60 minutes, and scrape the stirring blade and the barrel on the time of 20 minutes, 40 minutes and 60 minutes Slurry, the temperature of the slurry is controlled between...

Embodiment 2

[0042] Lithium titanate prepared by rutile titanium dioxide is used as the negative electrode, SP is the conductive agent, according to Li 4 Ti 5 o 12 : SP: CMC: SBR = 94.5: 2.0: 1.6: 1.9 mass ratio, solvent deionized water is 80% of the total amount of the above components. The preparation steps are as follows:

[0043] 1. Add the thickener CMC into the deionized water solvent, dissolve it evenly with a mixer, take it out for use, and the time is 120 minutes;

[0044] 2. Add the negative electrode active material and conductive agent into the mixing tank to stir and disperse for 40 minutes, and scrape the powder on the stirring blade and the barrel at the time of 20 minutes and 40 minutes;

[0045] 3. Add 60% of the total amount of thickener solution to the above stirred powder, stir and disperse for 70 minutes, and scrape the stirring blade and the barrel at 23 minutes, 46 minutes and 70 minutes Slurry, the temperature of the slurry is controlled between 25 and 35°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com