Method for manufacturing electrostatic power machine

A power machine and electrostatic technology, which is applied in the field of physics teaching experiment instruments, can solve the problems of lack of electrostatic power machine design and device, lack of innovation in electrostatic power demonstration experiments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

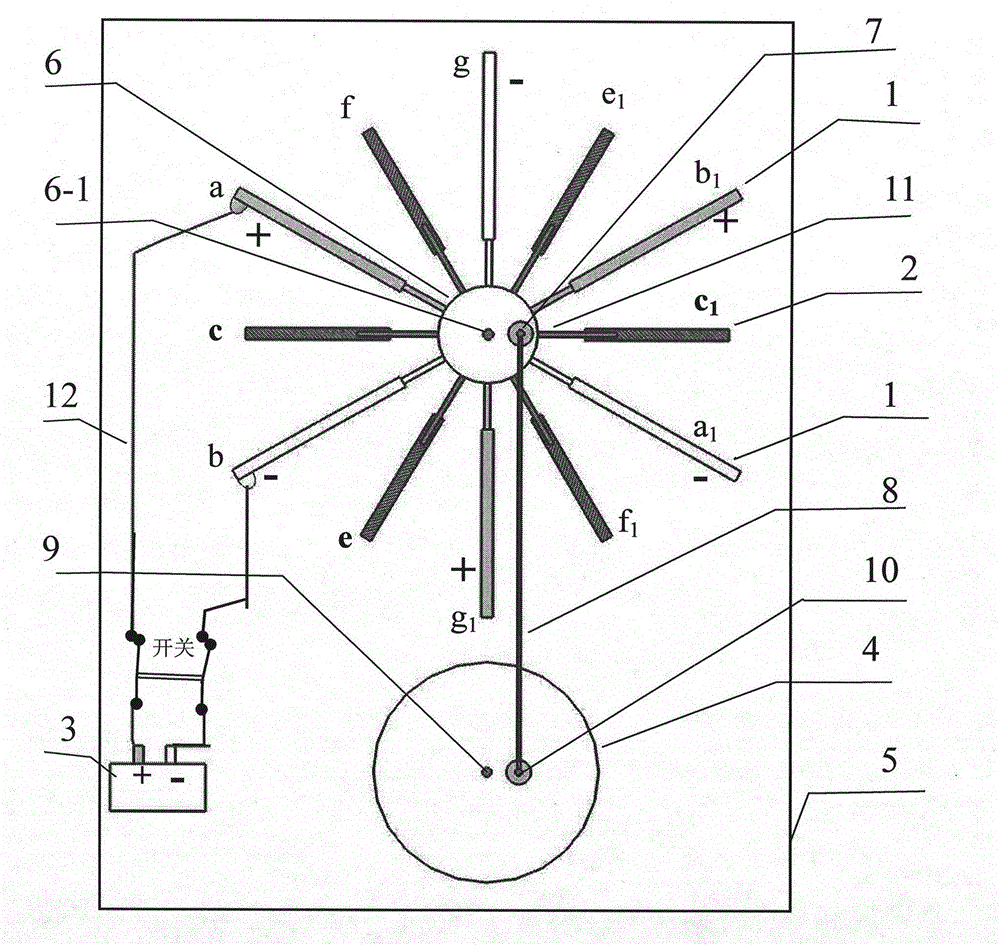

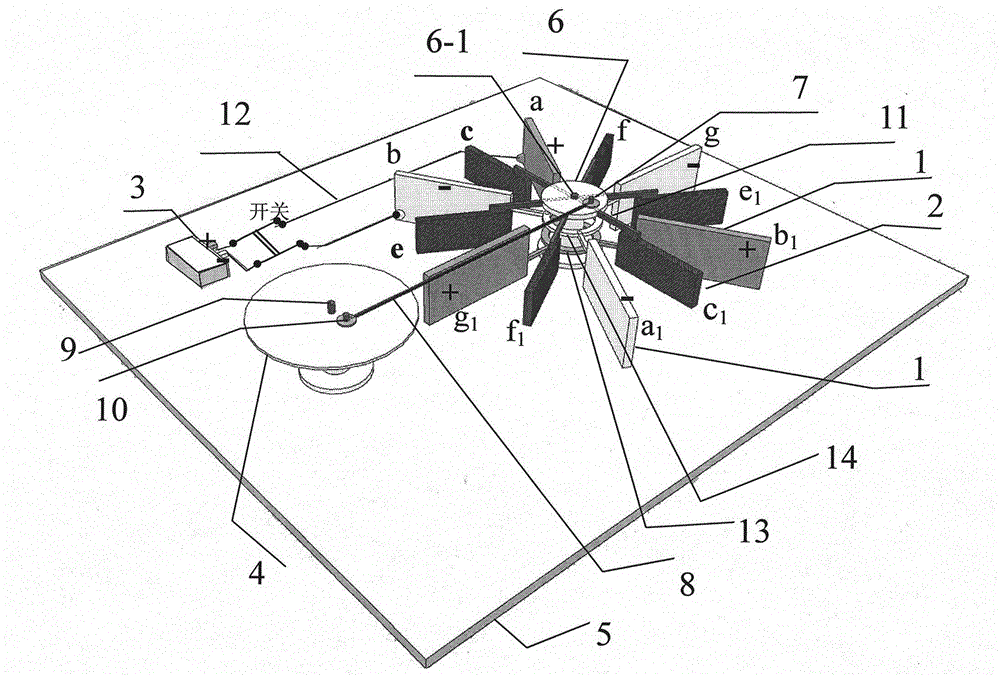

[0015] Taking the number of electrode plates N=6 as an example as a further specific implementation description

[0016] as attached figure 1 with attached figure 2 A kind of method of making electrostatic power machine, mainly is made of electrode plate (1), swing plate (2), high-voltage electrostatic power supply (3), runner (4), motion conversion lever (8), is characterized in that: The electrode plate (1) includes a metal conductor plate a and a metal conductor plate a 1 , metal conductor plate b and metal conductor plate b 1 And metal conductor plate g and metal conductor plate g 1 , the metal conductor plate a and the metal conductor plate a 1 , metal conductor plate b and metal conductor plate b 1 And metal conductor plate g and metal conductor plate g 1 Respectively parallel and take the plastic turntable rotating shaft (6-1) as the symmetry axis to equally divide the garden plane perpendicular to the plastic turntable rotating shaft (6-1), that is, the metal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com