Line laser sensor and method for calculating three-dimensional coordinate data of line laser sensor

A technology of three-dimensional coordinates and line laser, which applies online laser sensors and the calculation of three-dimensional coordinate data. In the field of welding, it can solve the problems of poor welding seam size accuracy and difficult application of teaching and reproduction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

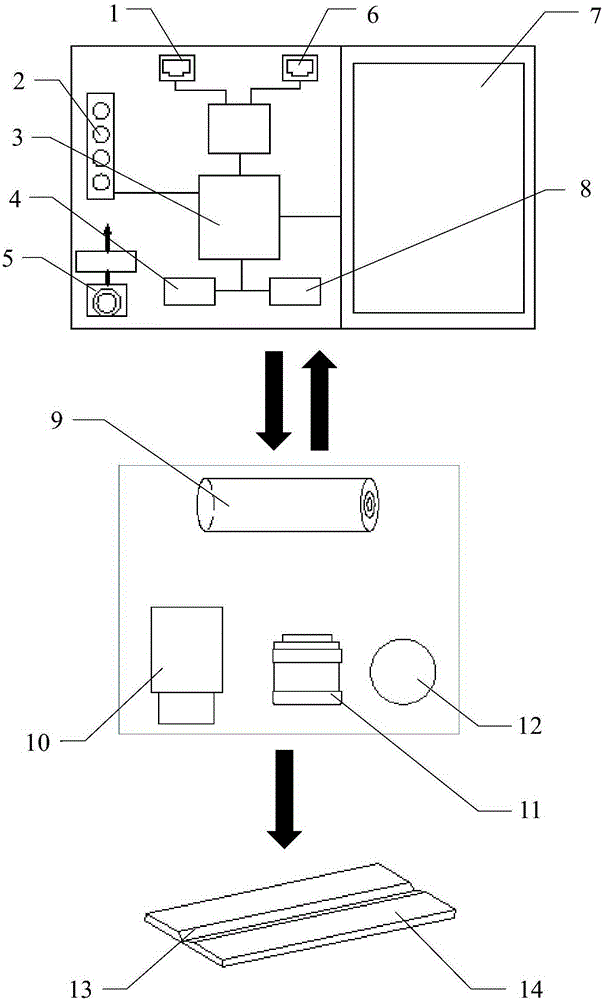

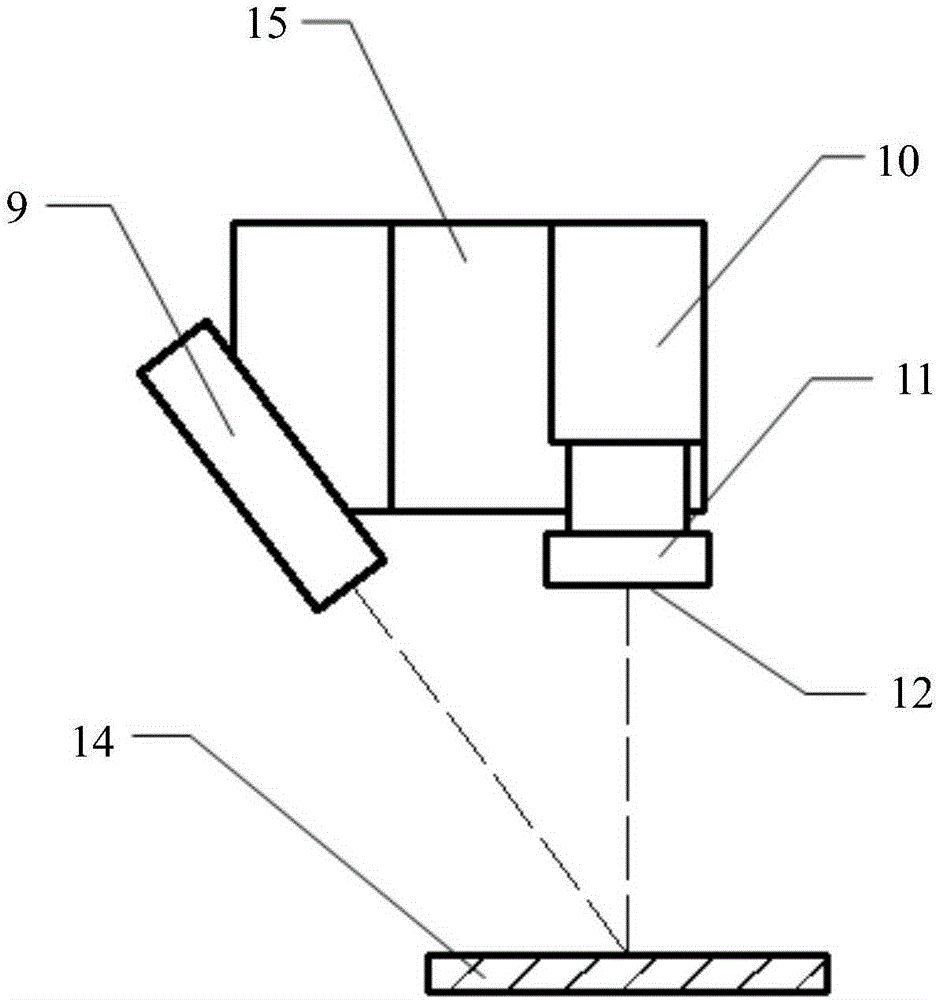

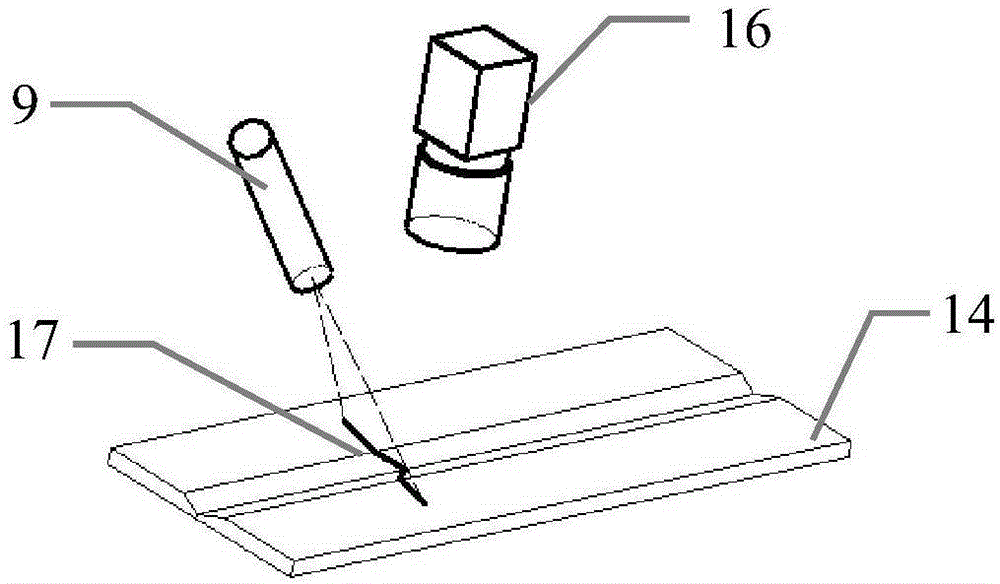

[0037] like figure 1As shown, it is a structural composition diagram of a line laser sensor for automatic welding equipment. The sensor is composed of a line laser emission module 9, an image acquisition module 16, and an image processing and control module:

[0038] Line laser generator module 9 has a power of 30mW and is composed of a semiconductor laser generator and a Powell linear prism to generate a line laser with a wavelength of 650nm;

[0039] The image acquisition module 16 includes an ACA type CMOS black and white industrial camera 10, an M0814 type fixed-focus lens 11 and a 30mm diameter filter 12 for image acquisition.

[0040] The image processing and control module includes a control circuit, an operating system and a control system.

[0041] The main units of the control circuit are: output Gigabit Ethernet interface 1; LED indicator light 2; DM3730 dual-core processor 3 of American TI Company, integrating 1GHz ARM CortexTM-A8 core and 800Hz DSP core; 512MB32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com