Group measurement method flatness detection device

A detection device and a technology of normal plane, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of easy misoperation of manual reading, high labor intensity, and high skill requirements of workers, so as to improve the measurement accuracy and work efficiency. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

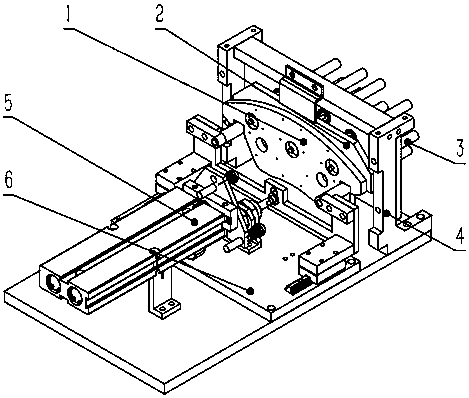

[0012] The present invention will be further described below in conjunction with accompanying drawing.

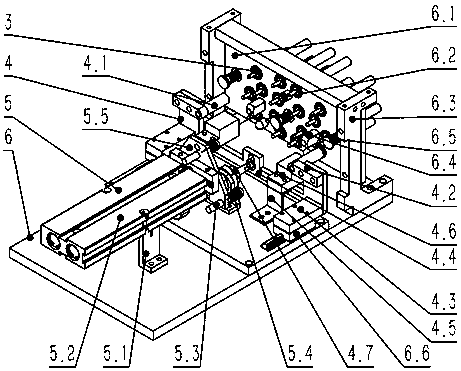

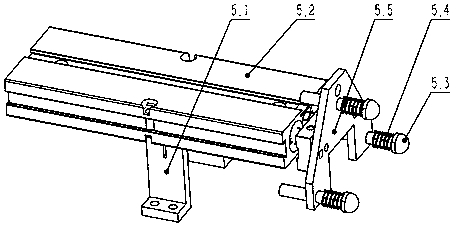

[0013] Such as figure 1 with figure 2 As shown, a flatness detection device includes a group measurement sensor group 3 , a detection and positioning device 4 , a workpiece adaptive pressing mechanism 5 and a frame 6 . The frame 6 is provided with a workpiece self-adaptive pressing mechanism 5 and a detection and positioning device 4 which is oriented and translated along the guide rail; the frame is provided with a fixedly installed group measuring sensor group 3 .

[0014] The group measurement sensor group 3 in the present embodiment comprises more than three LVDT sensor groups; The group measurement sensor group 3 is fixed on the frame 6 by the sensor mounting plate 6.1 and the sensor mounting plate bracket 6.3; the sensor mounting plate 6.1 is provided with three-point positioning Mechanism 6.2 and limit post 6.4.

[0015] The detection and positioning device 4 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com