A front feeding device for a section steel heating furnace

A section steel and driving device technology is applied in the field of charging device in front of a heating furnace, which can solve the problems of inability to separate section steel billets, potential safety hazards, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

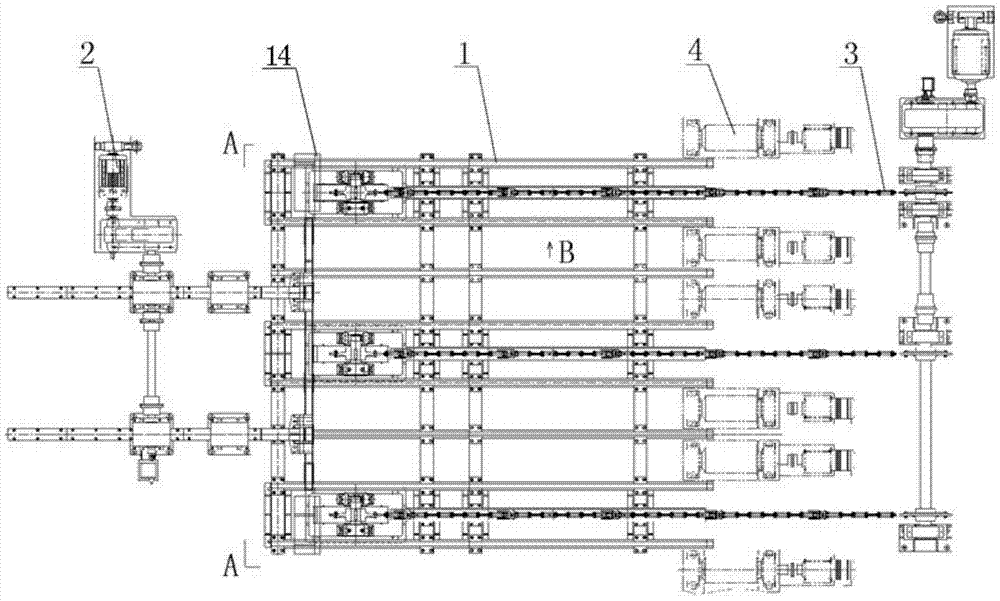

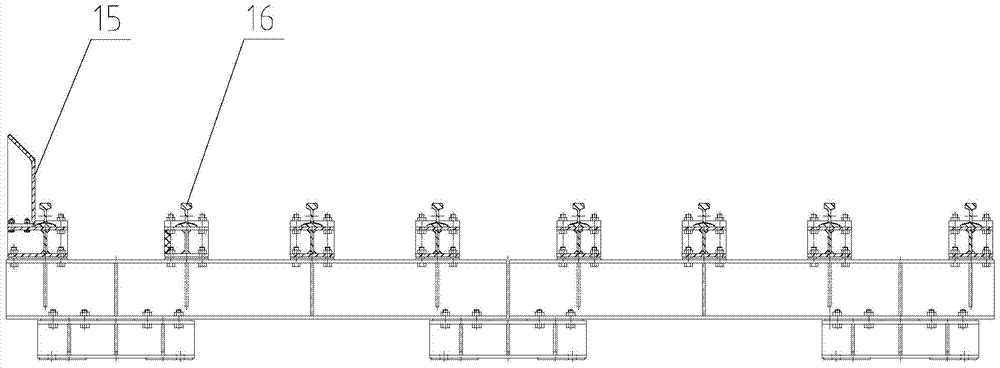

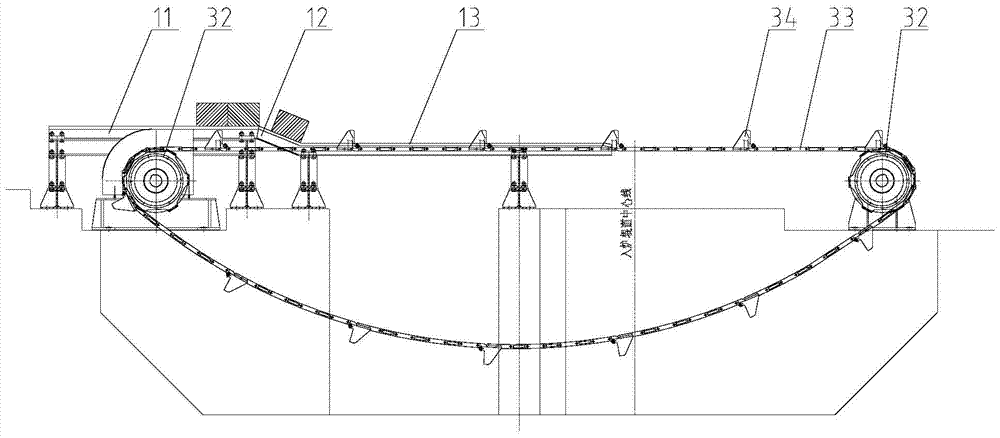

[0021] see Figure 1-Figure 3 , Is a schematic diagram of the structure of the present invention. The present invention is a front loading device for a section steel heating furnace, comprising a stepped platform 1, a steel pushing device 2 and a chain transmission device 3. The stepped platform 1 is composed of several parallel rail beams, including an upper platform 11. The transition table 12 and the lower table 13, in which the side of the lower table 13 is close to the section steel entering the furnace roller table 4; the steel pushing device 2 is arranged on the side of the upper table 11, and the pushing device 21 is connected in turn. , Gear 22, rack 23 and push rod 24 driven by the rack 23; on the other side of the section steel into the furnace roller table 4 is provided with a chain drive device 3, the multiple chains 33 can be driven by the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com