Water-tube type central-reverse-flame and condensation integrated boiler

A water tube type, integrated technology, applied in the field of water tube type central backfiring and condensing integrated furnace, can solve the problems of high heat resistance and sealing performance of the front smoke box, increase the operating cost of the boiler, and the boiler system is not compact enough, etc., to reduce the temperature , easy to manufacture, and the effect of avoiding weld corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

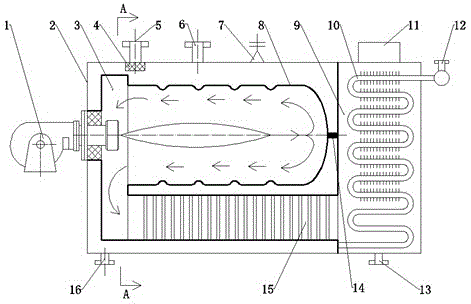

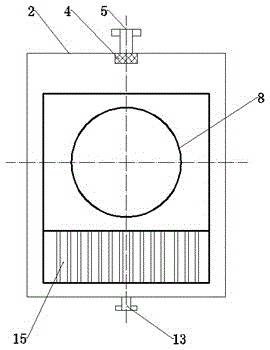

[0013] The specific implementation of the water tube type central flashback and condensing integrated furnace will be further described below in conjunction with the accompanying drawings.

[0014] The main components of the water tube type central backfiring and condensing integrated furnace include a burner, a shell, a furnace liner, a front smoke box, a water tube heat exchanger, a rear smoke box and an economizer. The boiler shell is a cuboid, which is formed by vertically butting and welding six flat plates; the flue gas heat exchange surface of the boiler includes the furnace gall, the front smoke box, the water tube heat exchanger and the economizer, the furnace gall, the water tube heat exchanger and the The front smoke box is connected by welding, and the furnace, front smoke box and water tube heat exchanger are all immersed in the furnace water to form a fully wet back structure.

[0015] The combustion method in the furnace is central back-burning. For small boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com