Pipeline heating deflation valve and rotation closed type hydraulic system of crane

A technology of air release valve and pipeline, applied in the field of rotary closed hydraulic system, can solve the problems of oil heating and high cost of artificial exhaust, and achieve the effect of avoiding manual operation and reducing labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

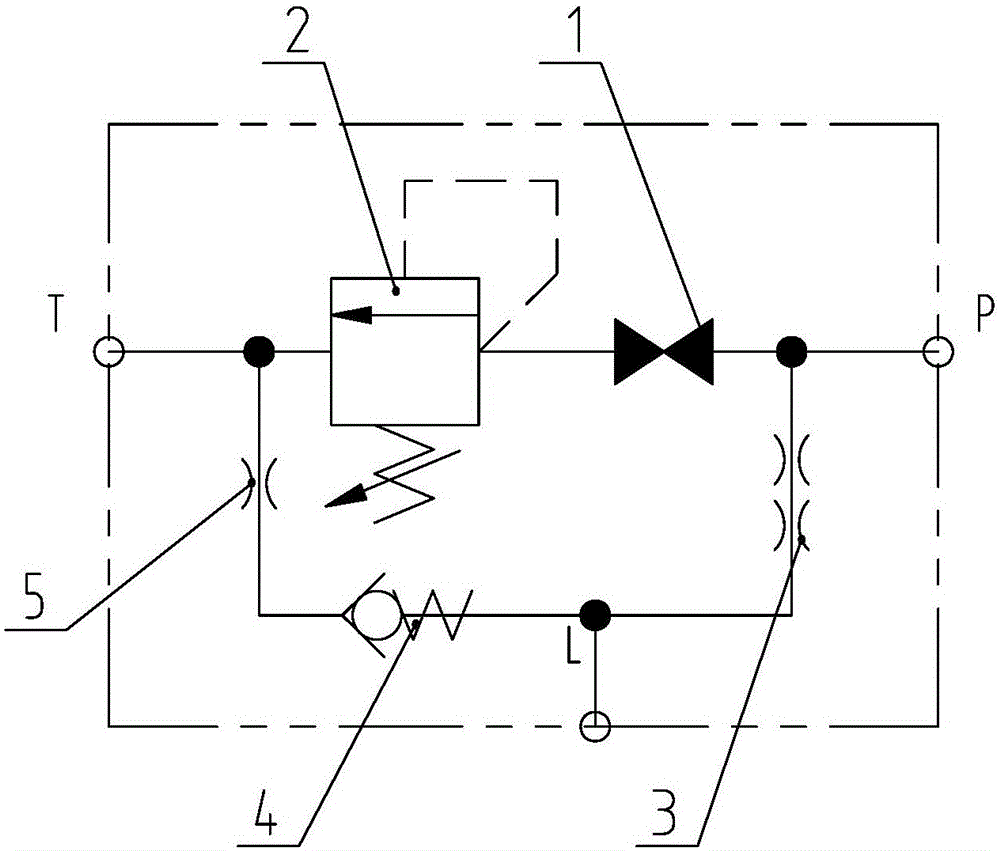

[0024] The embodiment of the present invention provides a pipeline heating and deflation valve, which is suitable for closed hydraulic systems where the working environment temperature is low (below 15°C) and the pipeline is easy to mix with air, such as figure 1 As shown, the pipeline heating purge valve includes: cut-off valve 1, overflow valve 2, first restrictor 3 and check valve 4, the oil outlet of cut-off valve 1 communicates with the oil inlet of overflow valve 2 , the oil inlet of stop valve 1 communicates with the oil inlet of first restrictor 3, the oil outlet of first restrictor 3 communicates with the oil outlet of check valve 4, and the oil inlet of check valve 4 It communicates with the oil outlet of the overflow valve 2 , and an oil drain L is arranged on the pipeline between the oil outlet of the check valve 4 and the oil outlet of the first restrictor 3 . The oil drain port L is used to connect with the leakage pipe in the pipeline of the hydraulic system.

...

Embodiment 2

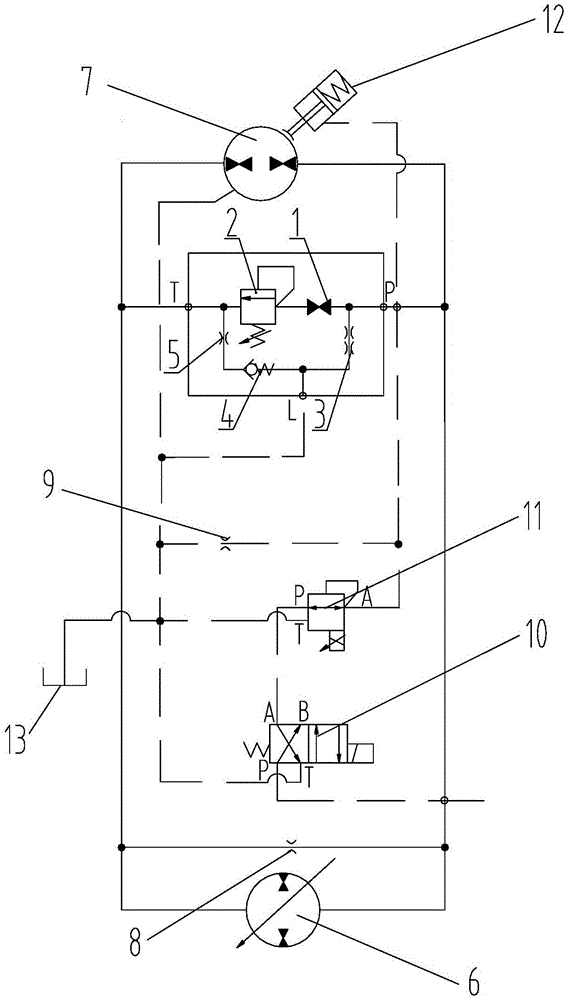

[0039] The embodiment of the present invention provides a rotary closed hydraulic system of a crane, including: a closed hydraulic pump 6, a rotary motor 7, a buffer damper 8, a fixed damper 9, a two-position four-way reversing valve 10, a pressure reducing valve 11 and The brake cylinder 12, the oil outlet of the closed hydraulic pump 6 is connected with the oil inlet of the rotary motor 7, the oil outlet of the rotary motor 7 is connected with the oil inlet of the closed hydraulic pump 6, and the two ends of the buffer damper 8 are respectively It is connected with the oil inlet and outlet of the rotary motor 7, the A port of the two-position four-way reversing valve 10 is connected with the P port of the pressure reducing valve 11, and the A port of the pressure reducing valve 11 is connected with the brake cylinder 12. The rod cavity is connected, the T port of the two-position four-way reversing valve 10 and the T port of the pressure reducing valve 11 are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com