Electric servo hydraulic power source drive system of four-foot robot

A quadruped robot and drive system technology, applied in fluid pressure actuation system components, servo motors, servo motor components, etc., can solve the problems of high energy consumption, high noise, heavy battery and motor weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

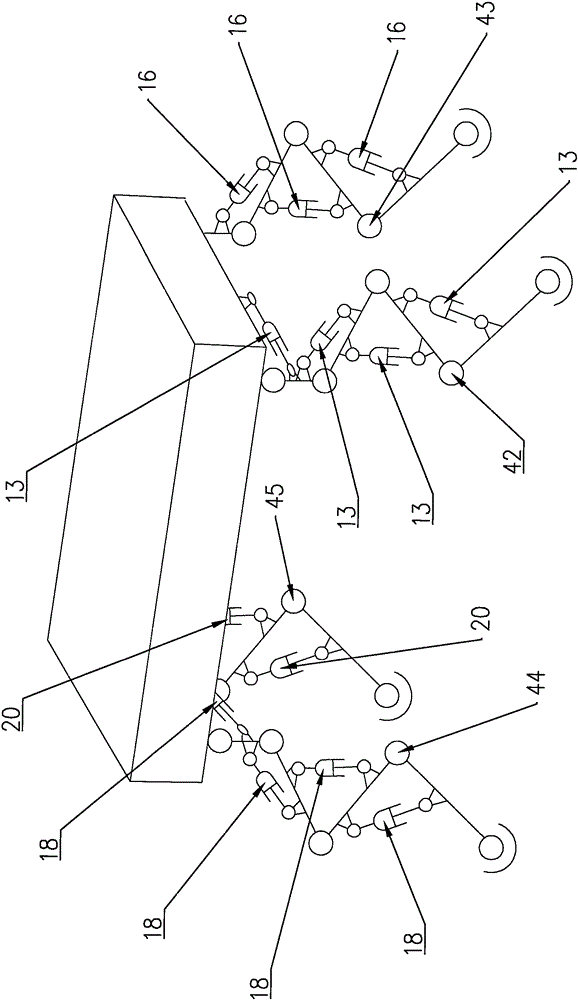

[0018] Such as figure 1 As shown, the quadruped robot electroservohydraulic source drive system of the present invention includes quantitative gear pump 2 and generator (not shown in the figure) driven by engine 1, the oil outlet of quantitative gear pump 2 and the connection of high-pressure oil pipe 4 The inlet is connected, and the middle part of the high-pressure oil pipe 4 is connected with the high-pressure oil pipe check valve 5, the filter 6 and the accumulator 7 sequentially from front to back, and the outlet of the high-pressure oil pipe 4 is connected with the inlet of the left oil supply pipe 30 and the right oil supply pipe 31. The inlet is connected; the filter 6 can filter the oil to ensure the cleanliness of the oil in the system.

[0019] A left hydraulic pump 32 is connected in series on the left fuel supply pipe 30, and the left hydraulic pump 32 is driven by a servo motor. A left overflow valve 41 is connected in series in the middle of the left overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com