Energy-saving control method for compressed air industrial screw-type air compressor group control system

A compressed air, energy-saving control technology, applied in the direction of machines/engines, etc., can solve the problems of increasing system maintenance costs and high renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

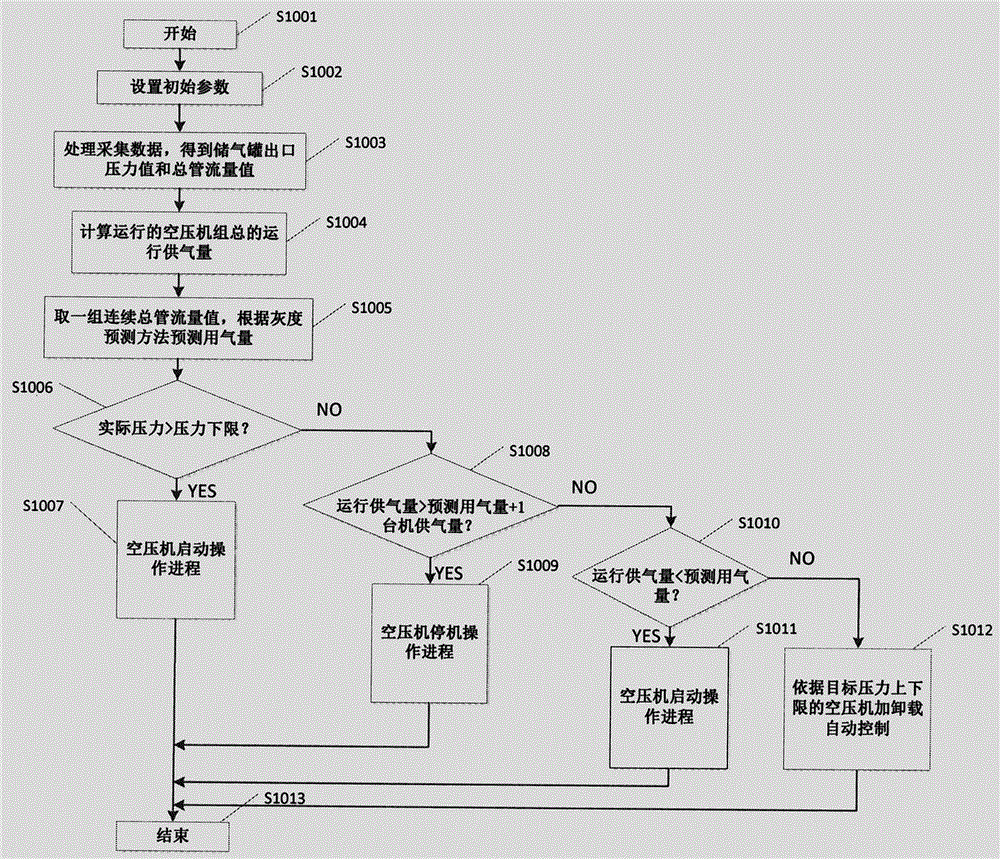

[0056] Such as image 3 As shown, the automatic control method for the number of air compressors includes the following steps:

[0057] S1001, start;

[0058] S1002. Set the initial parameters, the parameters include: system pressure lower limit value P Ldown ; Air compressor start delay time Ts; Air compressor stop delay time Te.

[0059] S1003. Process the collected data to obtain the output pressure value P of the gas storage tank 总 The flow value Q of the compressed air main pipe after the air storage tank 需 .

[0060] S1004. Calculate the total operating flow Q that the air compressor unit can provide 供 , the formula is:

[0061]

[0062] Among them, n is the number of air compressor units, k (i) is the operating state of the i-th air compressor unit, Q (i) is the rated flow rate of the i-th air compressor unit, k (i) Satisfy:

[0063]

[0064] In S1005, take 5 continuous time flow values Q 需 Generate a random sequence:

[0065] x i (0) (i=1, 2, ...,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com