Ultralow-temperature waste heat compound heating recycling system and recycling method

A technology of combined heating and recovery methods, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of impossibility of heat energy recovery, increased investment, low thermal efficiency of heat recovery cycle, etc., and achieve huge environmental protection and energy saving benefits , the effect of increasing enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

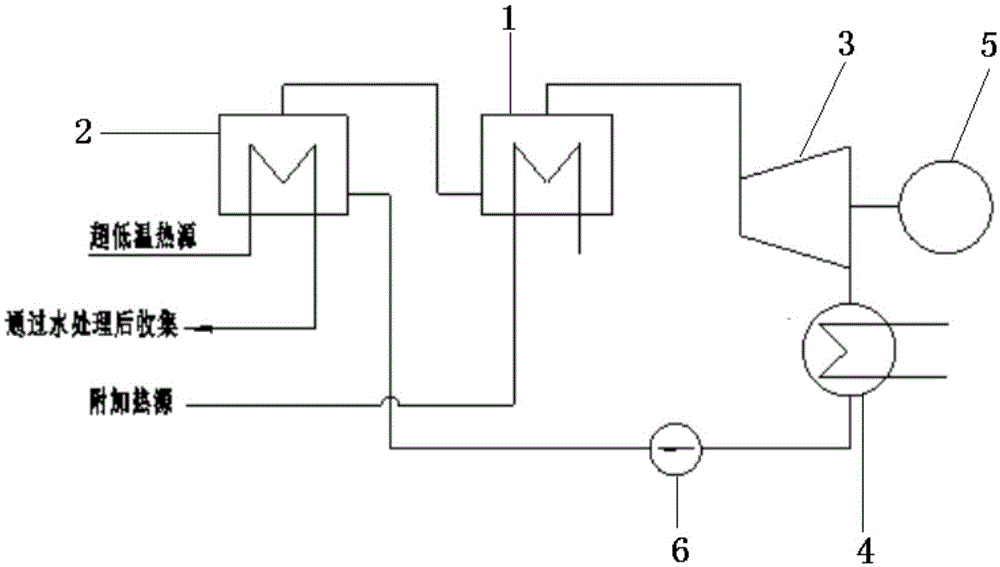

[0034] An ultra-low temperature waste heat composite heating recovery system, such as figure 2 As shown, it includes a circulation system composed of an evaporator, a steam turbine connected to a generator, a condenser, and a working medium pump; wherein, a heat exchanger is also connected to the inlet of the evaporator.

[0035] Using the above system to achieve ultra-low temperature waste heat compound heating recovery, the specific steps are as follows:

[0036] (1) Collect ultra-low temperature heat sources (specifically, steam evaporated from fermentation and drying), and the temperature is 65°C;

[0037] (2) The ultra-low temperature heat source enters the heat exchanger, and the ultra-low temperature heat source is heated by using the high temperature heat source (specifically, the degree of superheat of superheated steam);

[0038] (3) The heated ultra-low temperature heat source enters the evaporator to heat the organic working medium (specifically F245A), so that t...

Embodiment 2

[0043] An ultra-low temperature waste heat composite heating recovery system, such as image 3 As shown, it includes a circulation system composed of an evaporator, a steam turbine connected to a generator, a condenser, and a working medium pump; wherein, a heat exchanger is also connected at the outlet of the evaporator.

[0044] Using the above system to achieve ultra-low temperature waste heat compound heating recovery, the specific steps are as follows:

[0045] (1) Collect the ultra-low temperature heat source (specifically, the steam evaporated from the drying of the paper machine), and the temperature is 60°C;

[0046] (2) The ultra-low temperature heat source enters the evaporator to heat the ammonia water, so that the ammonia water produces medium and low pressure ammonia vapor; the ultra-low temperature heat source is collected after water treatment;

[0047] (3) The gained middle and low pressure ammonia steam enters the heat exchanger, and the middle and low press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com